A parabolic trough solar collector

A trough-type solar collector technology, which is applied in solar collectors, solar collectors using working fluid, solar thermal energy, etc., can solve the problems of heavy installation and commissioning, high mirror damage rate, and light conversion efficiency. Low-level problems, to achieve the effects of reduced maintenance costs, high light-gathering efficiency, and low process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] DETAILED DESCRIPTION OF THE INVENTION The specific embodiments of the present invention will be further described below with reference to the accompanying drawings:

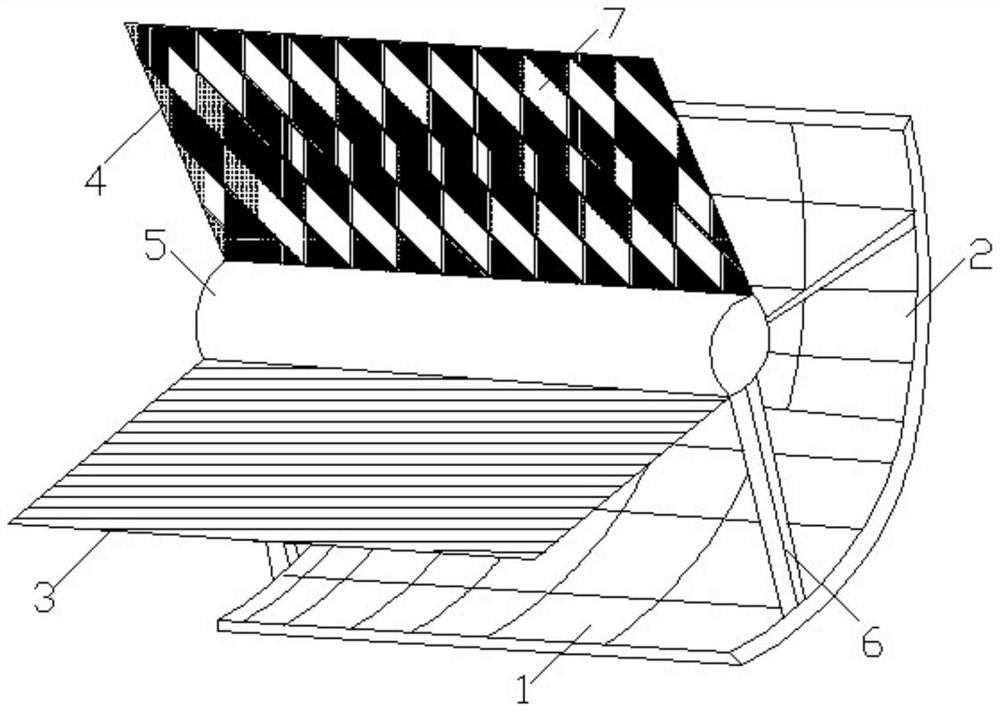

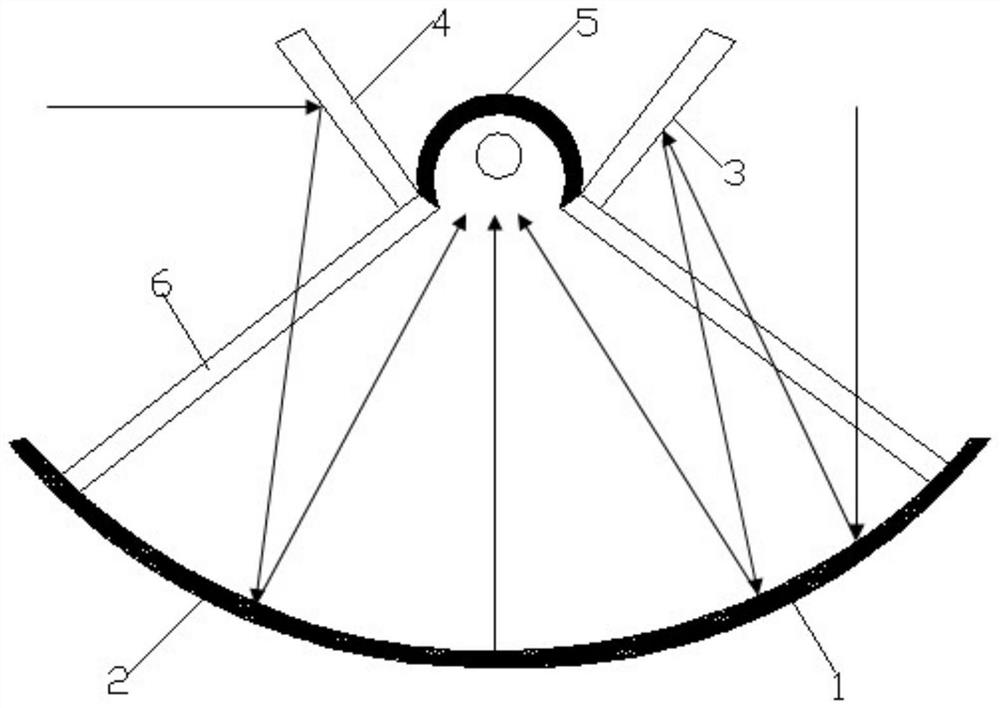

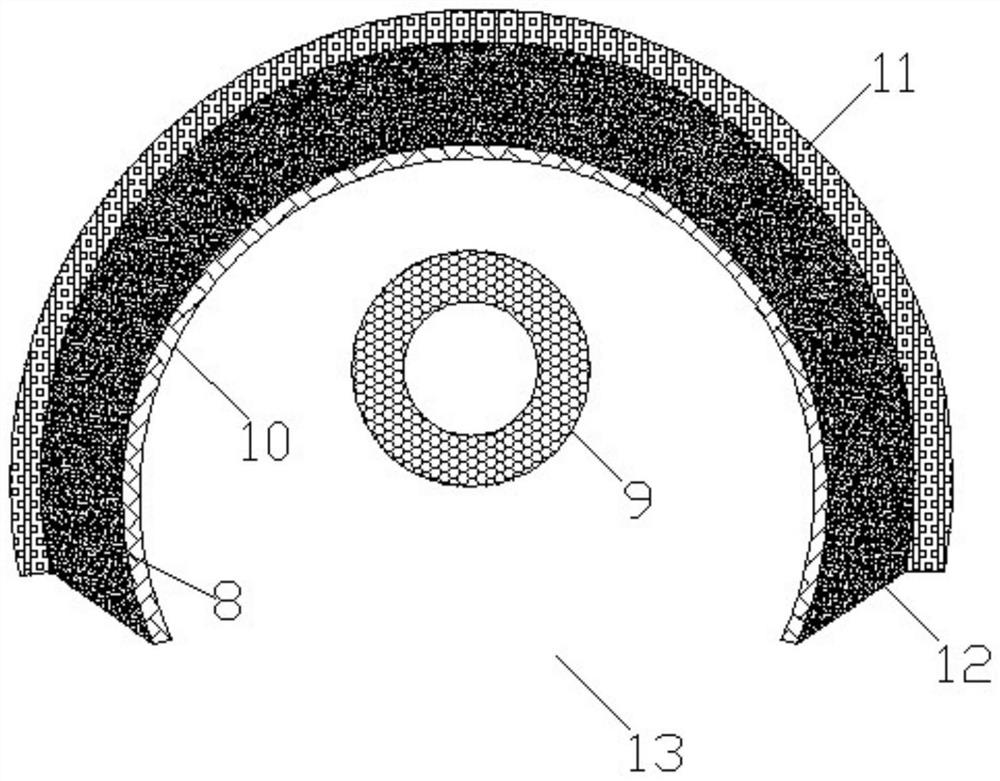

[0034] like figure 1 with figure 2 , The present embodiment provides one kind of parabolic trough solar collector assembly 6 comprises a support, a reflective assembly endothermic assembly 5, the assembly comprises a first reflecting parabolic concentrator trough 1 and a second parabolic concentrator trough 2, and a first plane mirror 3 and second flat mirror 4, the first plane mirror 3 and second flat mirror 4 are laid in the first trough and a second parabolic concentrator trough parabolic concentrator reflective front end 2; and a first plane mirror 3 and second flat mirror or a polygon defines a plurality of strip 4 into the aperture 7, the sun's rays directly incident through the aperture 7 into stripe or polygon to the entrance aperture 7 a first parabolic concentrator trough parabolic trough 1 and a sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| photothermal conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com