Laser beam focusing method and system for coupled water beam optical fiber

A focusing method and laser beam technology, applied in laser welding equipment, optics, light guides, etc., can solve the problems of poor beam quality, low water beam-beam coupling efficiency, and difficult water beam-beam coupling, etc., to reduce difficulty, Improved energy density and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with examples, but the present invention is not limited to these examples.

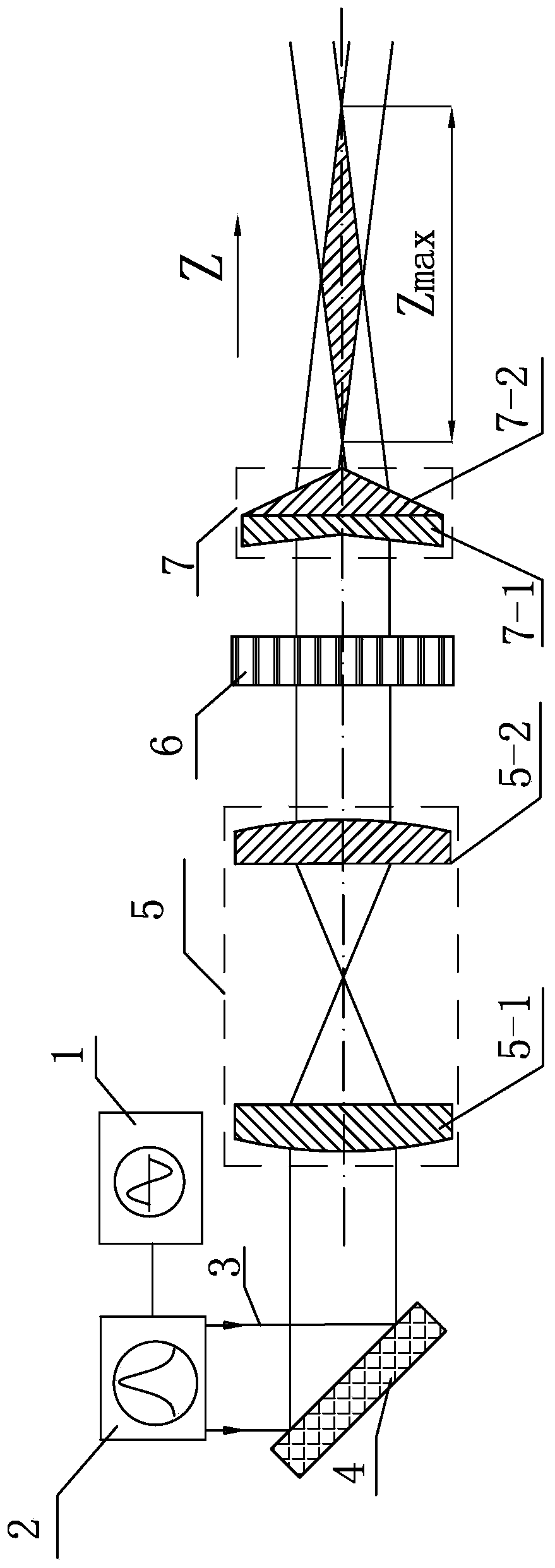

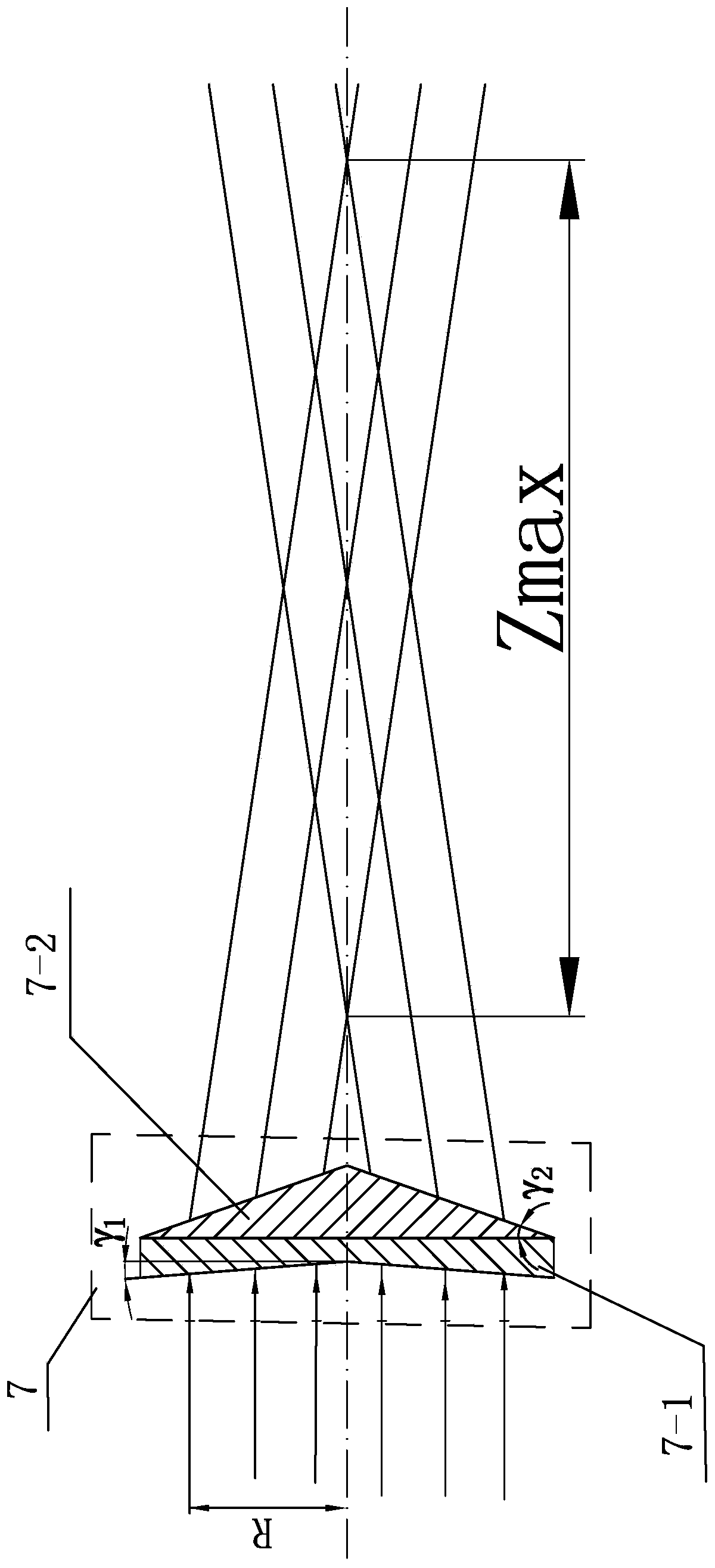

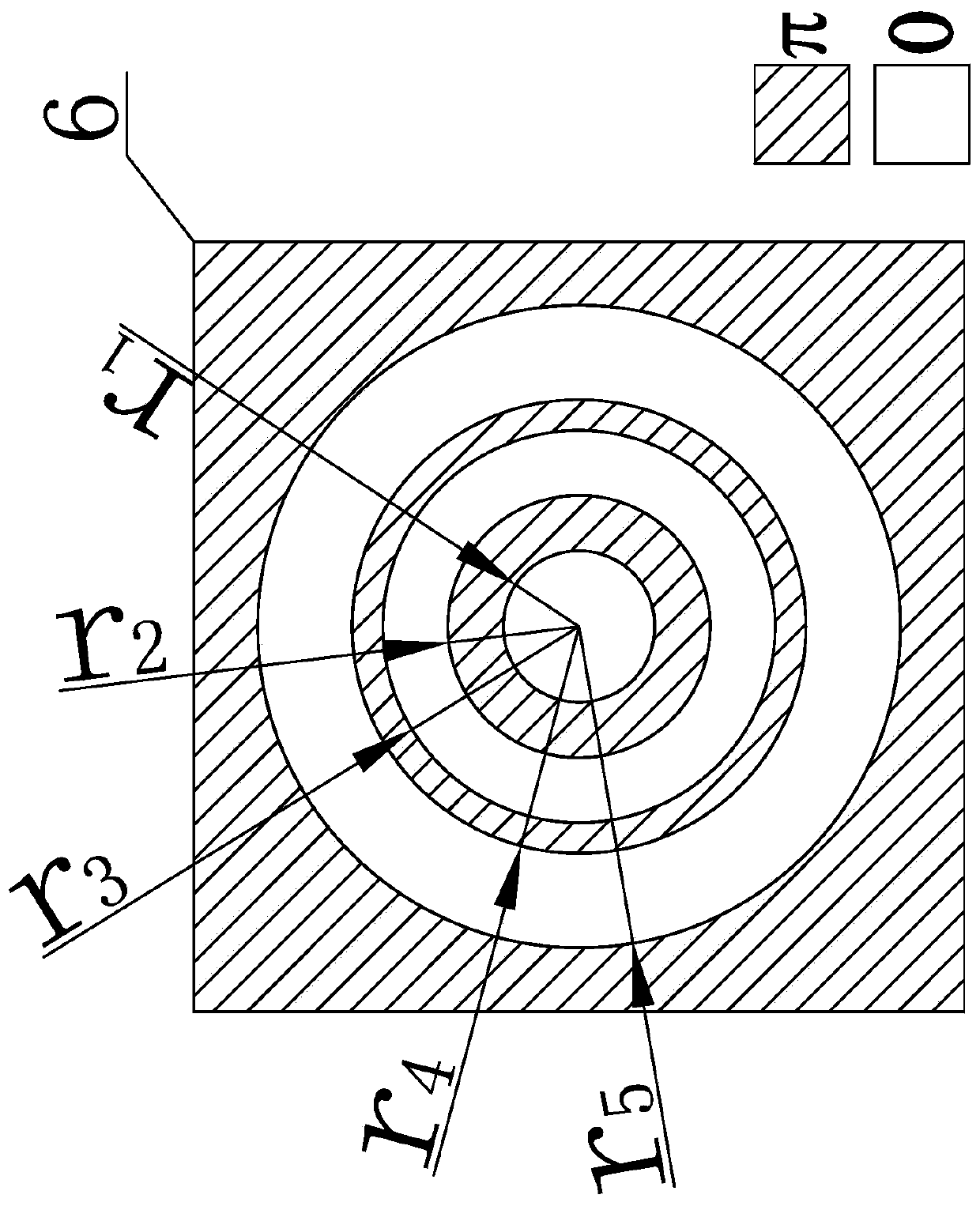

[0045] A laser beam focusing system coupled with a water beam optical fiber, comprising a controller 1, a laser transmitter 2, a mirror 4, a laser beam collimating and expanding unit 5, a phase plate 6, and a positive / negative axis prism combination unit 7; Said laser beam collimation beam expansion unit 5, phase plate 6 and positive / negative axicon mirror combination unit 7 are coaxially arranged; said laser emitter 2 emits laser beam 3 to mirror 4 under the control of controller 1, said After the laser beam 3 is collimated and expanded by the laser beam collimation and expansion unit 5, it is incident on the phase plate 6 for phase modulation; the positive / negative axicon combination unit 7 is composed of a negative axicon 7-1 and a positive axicon 7-2, the light beam after the phase modulation is completed by the phase plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com