Corrosion-and fire-resistant pipe system

A pipeline system and fire extinguishing system technology, applied in the field of corrosion-resistant and fire-resistant pipeline systems, can solve problems such as casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

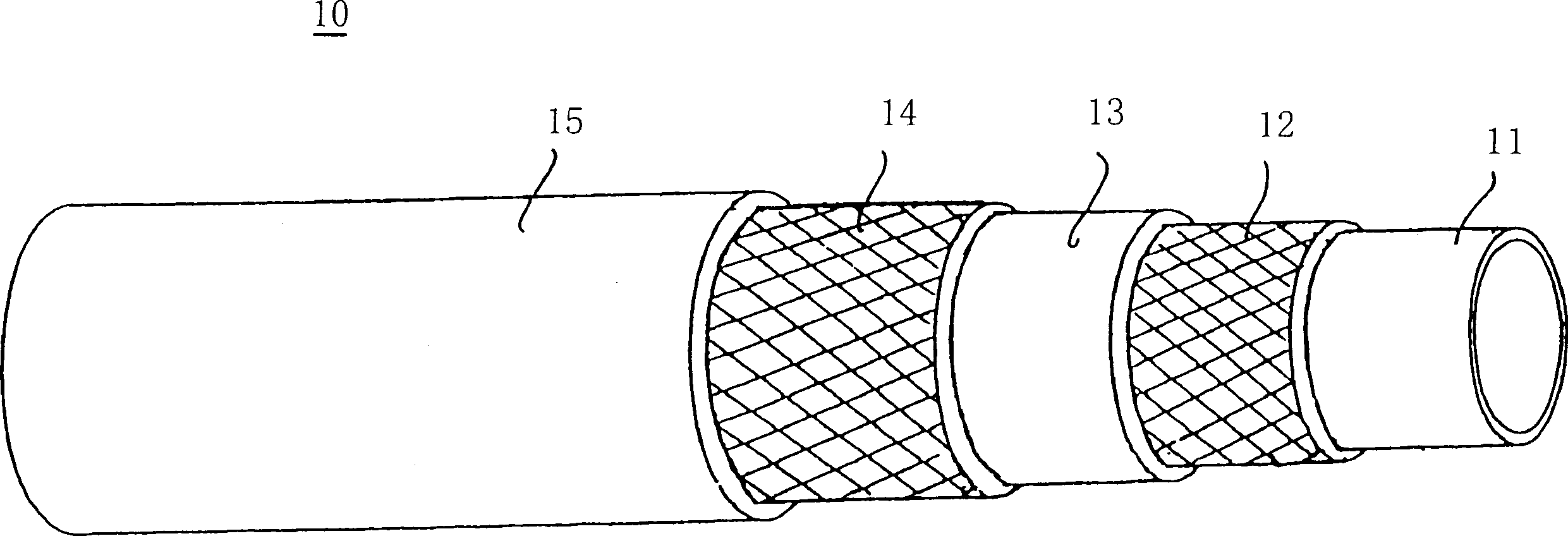

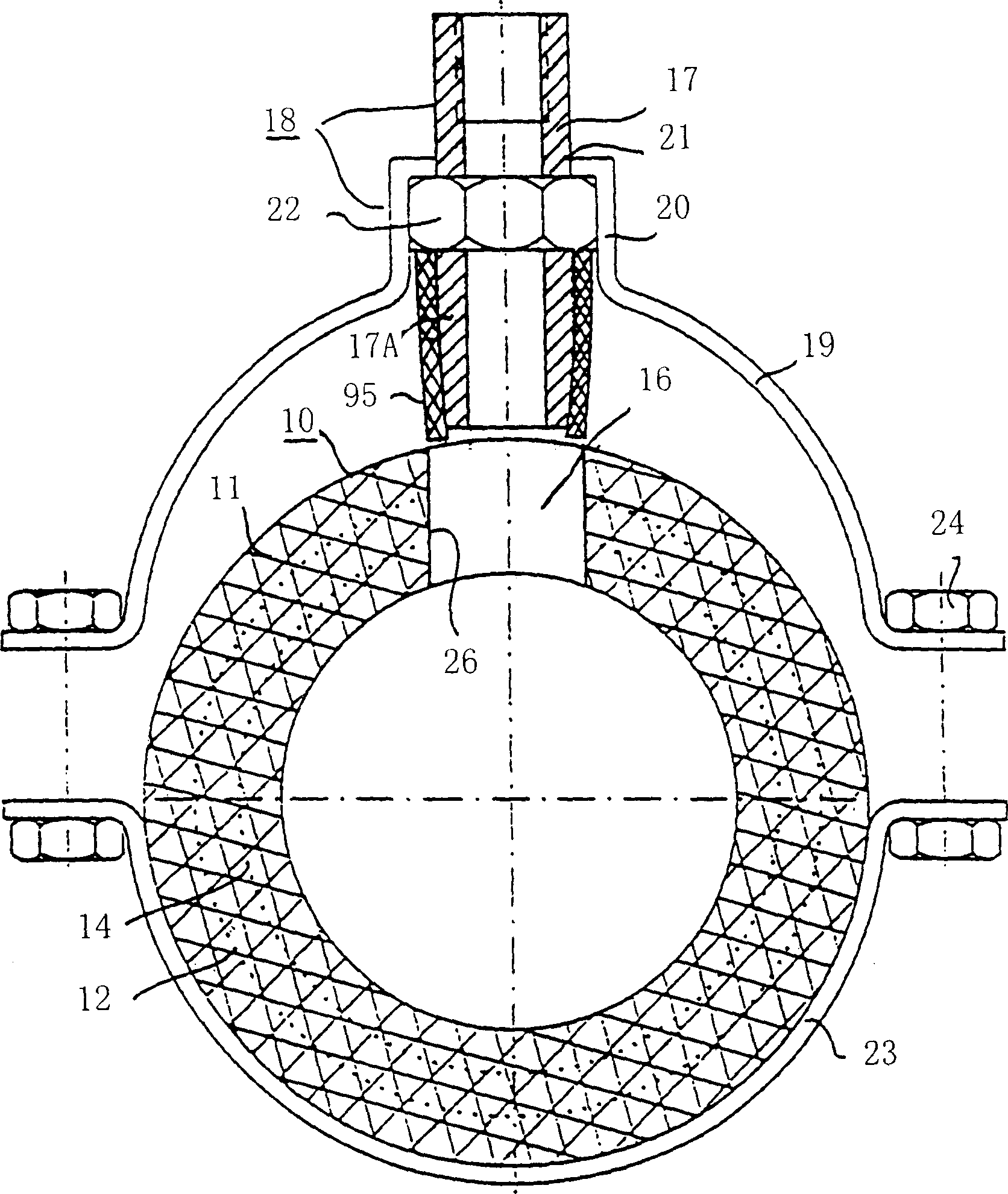

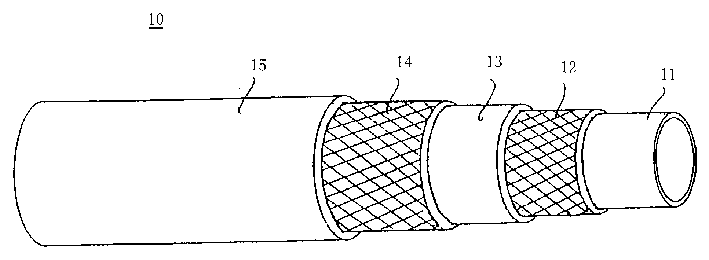

[0034] figure 1 Shown is an embodiment of a pipe segment or part of a pipe section 10 in which the rubber and reinforcing material are included in separate layers, the pipe section 10 thus comprising a material compatible with the liquid transported in the pipe The inner rubber layer 11. The inner rubber layer 11 is surrounded by a first reinforcing layer 12, in the illustrated case: a woven wire mesh, the wires on which have a winding angle of about 54° in both wire directions. The first reinforcing layer 12 is surrounded by an intermediate rubber layer 13 whose thickness is generally greater than that of the inner rubber layer 11 . The middle rubber layer 13 is surrounded by a second reinforcement layer 14 . Although in the case of the illustrated embodiment the second reinforcement layer is identical to the first reinforcement layer 12, it could also be different from the first reinforcement layer and still be within the contemplation of the present invention, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com