Production mechanism and process of novel high-valued oyster calcium feed additive

A feed additive and high-value technology, applied in the agricultural field, can solve problems such as industrialization difficulties and unstable conditions, and achieve the effects of prolonging the mixing time, accurately controlling the feeding amount, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

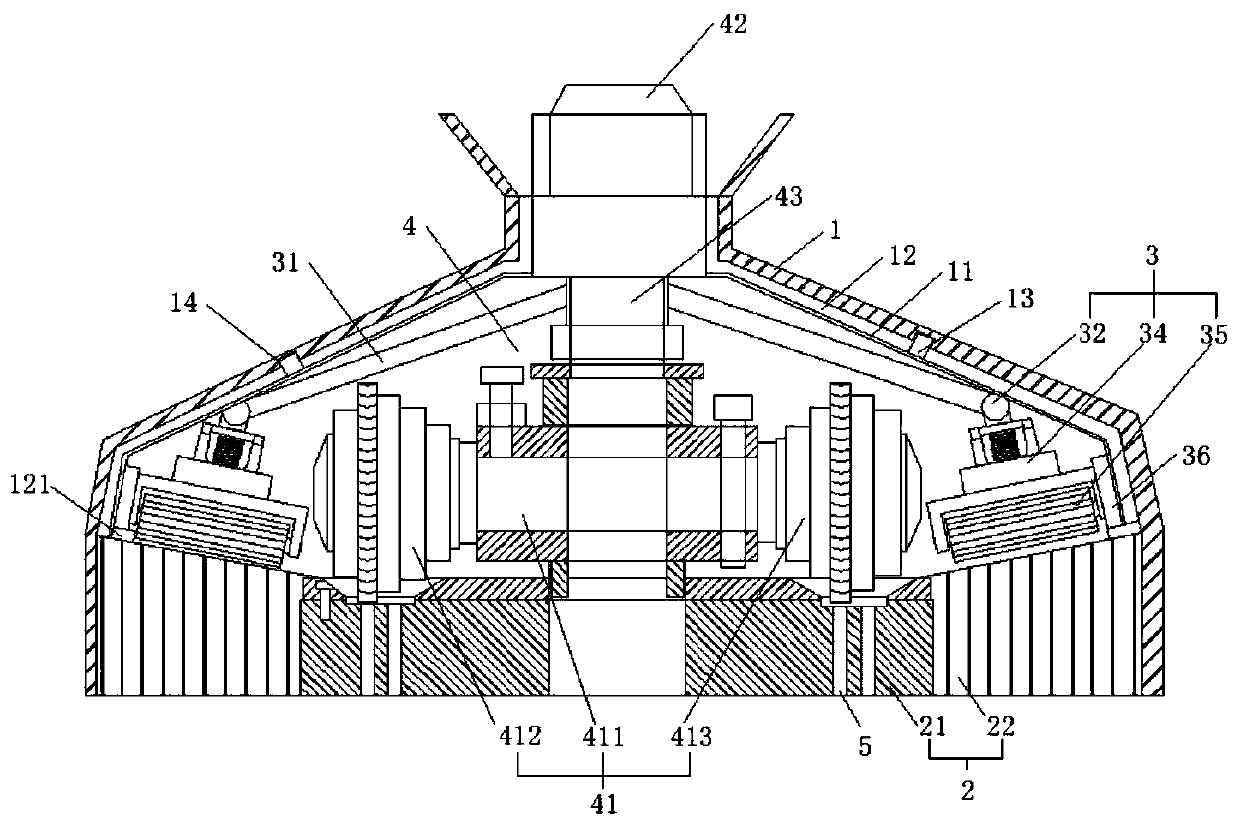

[0066] The production process of novel high-value oyster calcium chicken feed additive comprises the following steps:

[0067] Step 1: Put oyster shell powder, wheat, rice, and corn into the mixing feeding cavity in a weight ratio of 4:13:40:43;

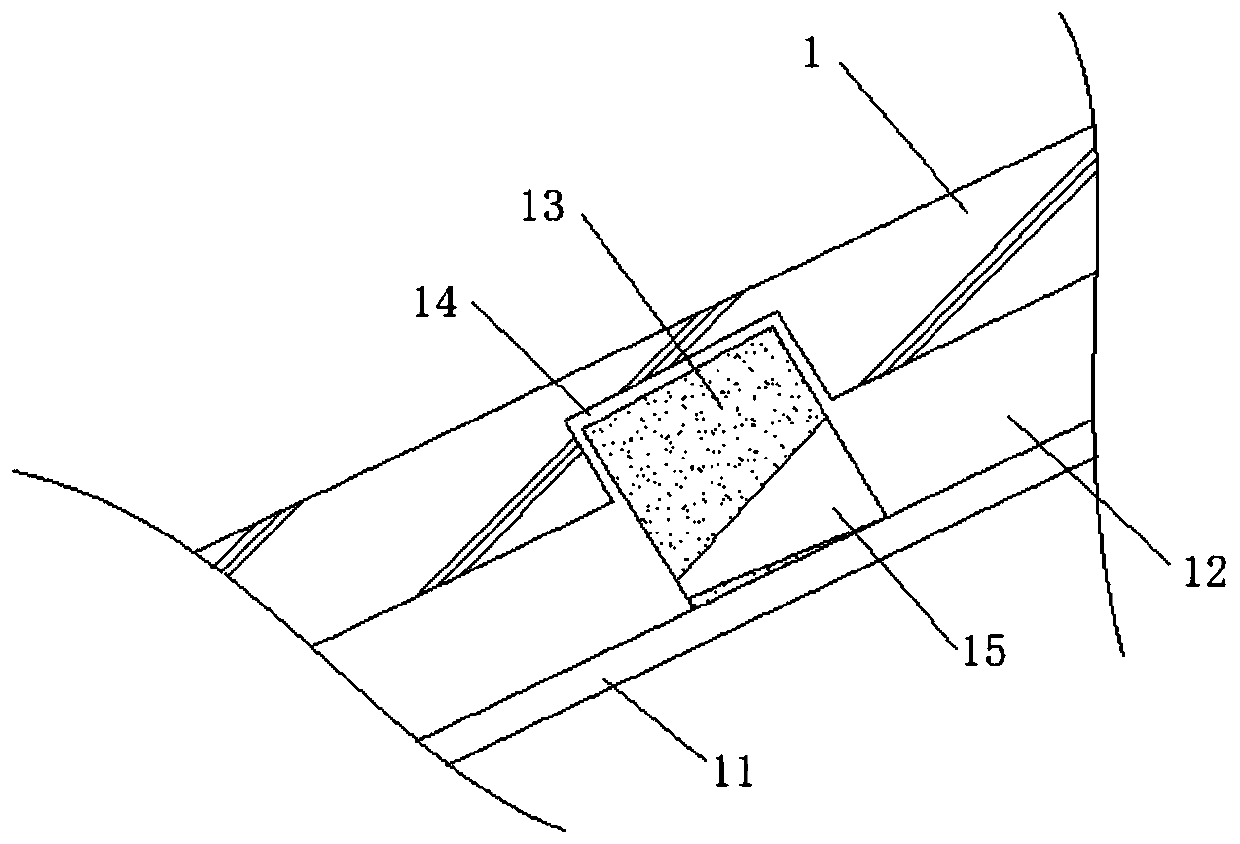

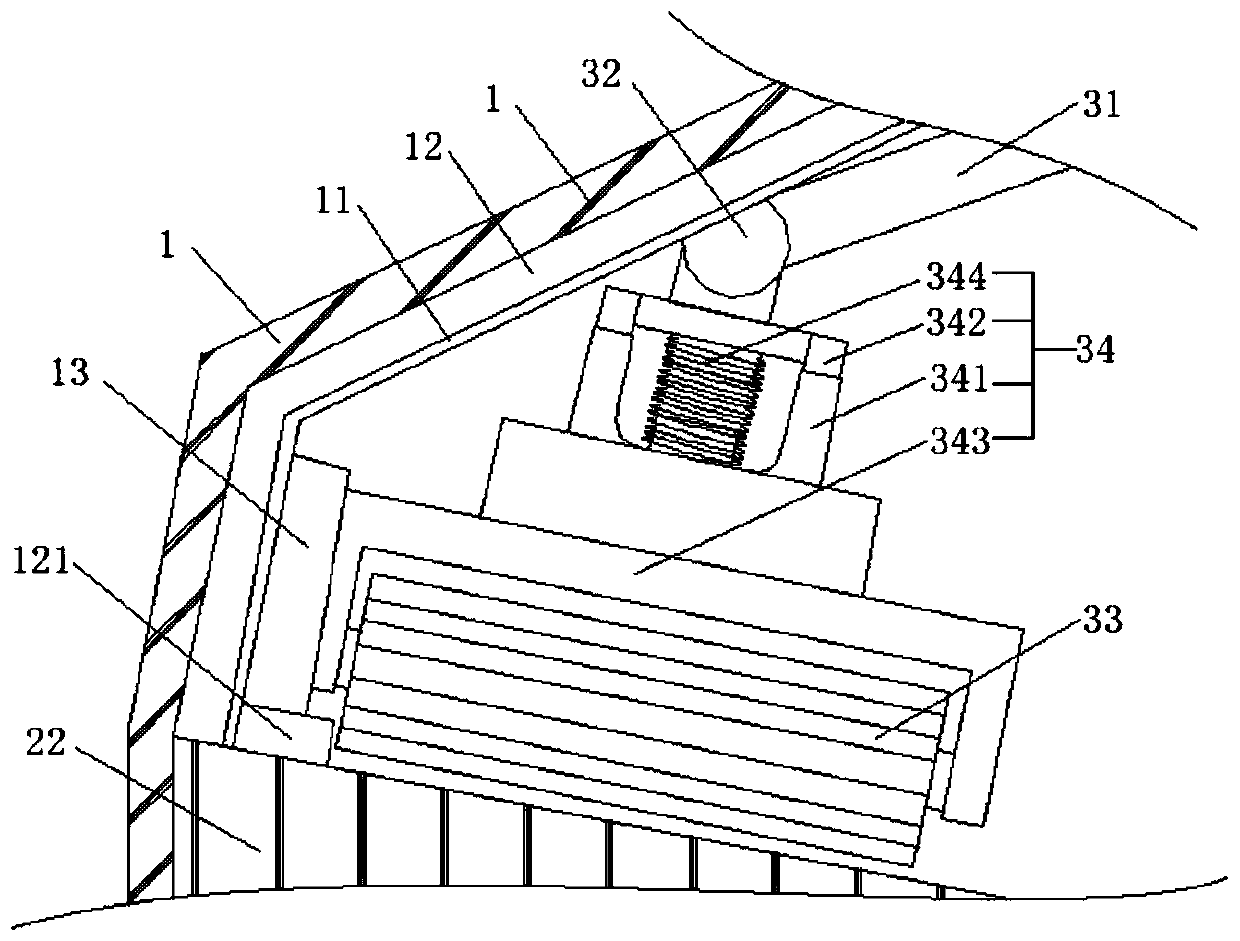

[0068] Step 2: Control the roller motor so that its rotation speed is 200 rpm to form a mixture of oyster shell powder, which enters the grinding part of the mold through the opening at the bottom of the mixing feeding cavity, and is pulverized into powder by the grinding assembly, and the particle size of the powder is controlled to be 0.05 ~ 0.5mm, and enter the granulation part of the die along the strip groove;

[0069] Step 3: Under the action of the rotation of the inner pressure roller and the outer pressure roller, the powder is pressed into the granulation through hole to form cylindrical particles with a height of 2.0 mm and a cross-sectional radius of 1.0 mm.

Embodiment 2

[0071] The production technology of novel high-value oyster calcium duck feed additive comprises the following steps:

[0072] Step 1: put oyster shell powder, fish grass, corn, and rapeseed meal into the mixing chamber according to the weight ratio of 5:28:53:14;

[0073] Step 2: Control the roller motor so that its rotation speed is 250 rpm to form a mixture of oyster shell powder, which enters the grinding part of the mold through the opening at the bottom of the mixing feeding cavity, and is crushed into powder by the grinding assembly, and the particle size of the powder is controlled to be 0.05 ~ 0.5mm, and enter the granulation part of the die along the strip groove;

[0074] Step 3: Under the action of the rotation of the inner pressure roller and the outer pressure roller, the powder is pressed into the granulation through hole to form cylindrical granules with a height of 6.0 mm and a cross-sectional radius of 2.0 mm.

Embodiment 3

[0076] The production process of the novel high-value oyster calcium pig feed additive comprises the following steps:

[0077] Step 1: put oyster shell powder, rice bran, corn, and soybean meal into the mixing feeding cavity in a weight ratio of 8:28:45:19;

[0078] Step 2: Control the roller motor so that its rotation speed is 250 rpm to form a mixture of oyster shell powder, which enters the grinding part of the mold through the opening at the bottom of the mixing feeding cavity, and is crushed into powder by the grinding assembly, and the particle size of the powder is controlled to be 0.05 ~ 0.5mm, and enter the granulation part of the die along the strip groove;

[0079] Step 3: Under the action of the rotation of the inner pressure roller and the outer pressure roller, the powder is pressed into the granulation through hole to form cylindrical granules with a height of 10.0 mm and a cross-sectional radius of 3.0 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com