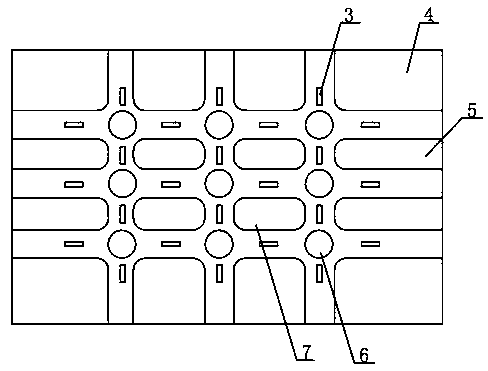

Manufacturing method of EPP (Expanded Polypropylene) non-slip floor mat for bathroom

A manufacturing method and anti-slip pad technology, which can be applied to other household appliances, household appliances, household components, etc., can solve problems such as poor user experience, hardened materials, wear resistance, service life and poor drainage, and achieve temperature balance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

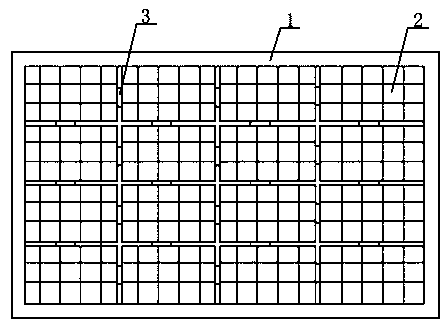

[0020] The purpose of the present invention is to provide a method for manufacturing EPP bathroom non-slip floor mats. The manufacturing steps of the EPP bathroom non-slip floor mats are as follows: prepare 500-600kg of expandable polypropylene raw materials; put the expandable polypropylene raw materials at a pressure of 20m³ In the container, keep the temperature at 30°C±5°C and the pressure at 0.8-1Mpa to pre-press for 12 hours; send the expandable polypropylene raw material that has completed the pre-pressing step into the mold of the steam foaming molding machine through a 2Mpa air compression device. Pre-foam in the steam foam molding machine for 5 seconds, open the steam channel of the steam foam molding machine, adjust the pressure in the steam foam molding machine to 2Mpa-3.5Mpa, heat up for 20-30 seconds, and weld the raw materials to make a poly Acrylic bathroom non-slip mat semi-finished products; turn on the steam foam molding machine and cool for 100-150 seconds. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com