Heat-resistant grease for gap type overhead conductor as well as preparation method and application thereof

An overhead wire, gap-type technology, applied in the field of grease, can solve the problems of weakening resistance to external erosion, reducing the service life of power lines, limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In the present invention, the preparation method of the polyurea-based composite thickener preferably includes the following steps: under normal pressure, add 1 / 2 base oil, p-toluidine and cyclohexylamine to the fat-making kettle, start mixing and heating , and add the adhesive; mix 1 / 2 base oil and diphenylmethane-4,4'-diisocyanate in an automatic mixer and heat; slowly add the isocyanate-base oil mixture into the fat-making kettle, mix with The organic amine-base oil mixture is fully reacted under stirring to obtain a thickener. In the present invention, the heating and mixing temperature of the 1 / 2 base oil and p-toluidine and cyclohexylamine is preferably 120~140°C; the 1 / 2 base oil and diphenylmethane-4,4'-bis The heating and mixing temperature of the isocyanate is preferably 80-120°C; the heating and mixing temperature of the two mixtures is preferably 150-200°C.

[0042] In the present invention, based on the mass parts of the base oil, the raw materials for pre...

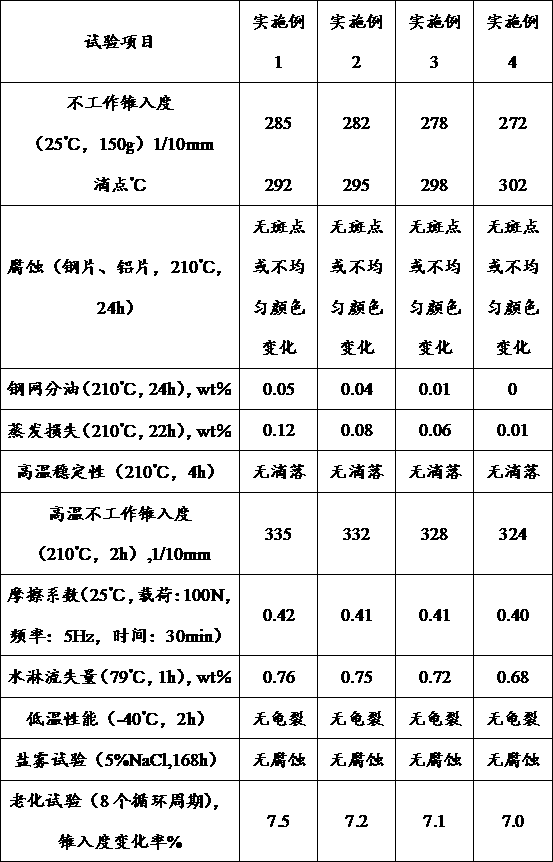

Embodiment 1

[0062] Put 80 parts of mixed base oil, 6 parts of p-toluidine and 18 parts of cyclohexylamine into the fat-making kettle, start mixing and heating, add 3 parts of adhesive (random polypropylene) at 60°C, mix and heat to 130°C; 80 parts of mixed base oil and 36 parts of diphenylmethane-4,4'-diisocyanate are mixed and heated in an automatic mixer, and the mixture is heated to 100°C; slowly add the isocyanate-base oil mixture into the fat-making kettle, mix with The organic amine-base oil mixture is fully reacted under stirring, mixed and heated to 180°C, and continued to stir for 30 minutes; after fat formation, then add 1.6 parts of antirust agent (neutral barium dinonyl naphthalene sulfonate) and 1.7 parts of antioxidant , 3.5 parts of oil separation inhibitor (modified nano-silicon dioxide), continue to heat to about 250 ° C for 2 hours, then add 6 parts of solid filler (mica powder), and then perform cyclic shearing, homogenization and degassing treatment, Obtain heat-resist...

Embodiment 2

[0065] Put 82 parts of mixed base oil, 6.5 parts of p-toluidine and 16 parts of cyclohexylamine into the fat-making kettle, start mixing and heating, add 3.5 parts of adhesive (random polypropylene) at 60°C, mix and heat to 130°C; 82 parts of mixed base oil and 35 parts of diphenylmethane-4,4'-diisocyanate are mixed and heated in an automatic mixer, and the mixture is heated to 100°C; slowly add the isocyanate-base oil mixture into the fat-making kettle, and mix with The organic amine-base oil mixture is fully reacted under stirring, mixed and heated to 180°C, and continued to stir for 30 minutes; after fat formation, then add 1.8 parts of antirust agent (neutral barium dinonyl naphthalene sulfonate) and 1.9 parts of antioxidant , 3.8 parts of oil separation inhibitor (modified nano-silicon dioxide), continue to heat to about 250 ° C for 2 hours, then add 6.5 parts of solid filler (mica powder), and then carry out cyclic shearing, homogenization and degassing treatment, Obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com