Rotary kiln residual refractory brick breaking device and method capable of accurately controlling breaking depth

A precise control, rotary kiln technology, applied in furnace, lining repair, lighting and heating equipment, etc., can solve problems such as precise adjustment of drill rod striking force, kiln body breakage, unusability, etc., to improve work efficiency and extend the kiln body. Longevity and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

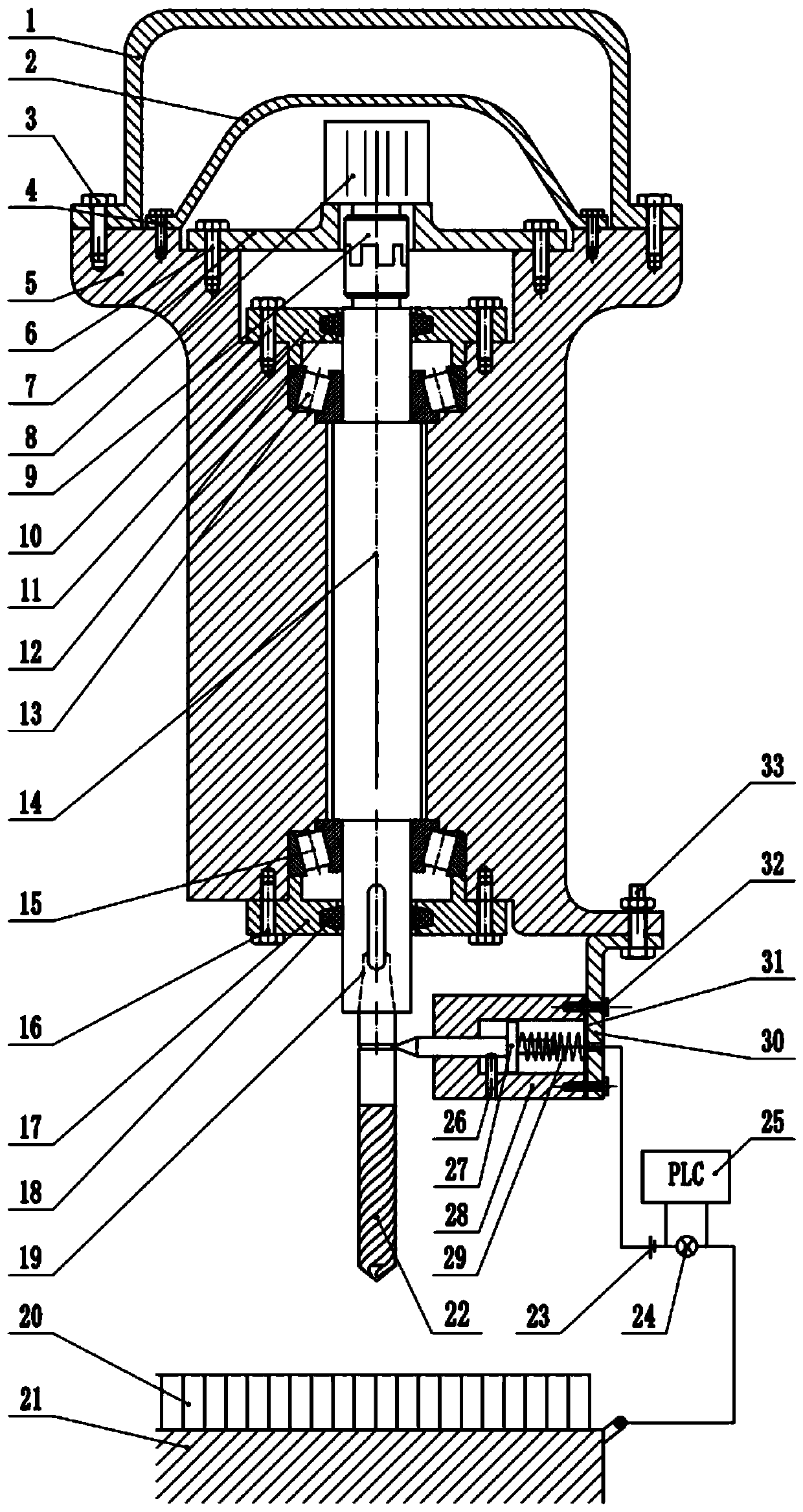

[0014] Such as figure 1 As shown, the device of the present invention includes a frame system, a rescue system and a control system.

[0015] The frame system includes a handle 1 , a shield 2 , a first bolt 3 , a second bolt 4 , and a body 5 . The handle 1 is fixed on the end face of the machine body 5 by the first bolt 3. The existence of the handle 1 is convenient for transportation and provides a point of strength during demolition operations. For the demolition on the side wall, the operator can hold the handle 1 with one hand and the other hand Hold the middle part of the body 5 by hand. The protrusion protruding from the lower end of the body 5 can also use the position of foot power for the workers of the demolition to increase the downward force of demolition. The shield 2 is fixed on the end face of the body 5 by the second bolt 4, which mainly prevents the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com