Distributed optical fiber sound wave and vibration fusion type sensing system

A distributed optical fiber, sensing system technology, applied in the measurement of ultrasonic/sonic/infrasonic waves, the use of wave/particle radiation, measurement devices, etc., can solve problems such as single vibration or acoustic wave sensing, to achieve cost savings, flexible operation, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

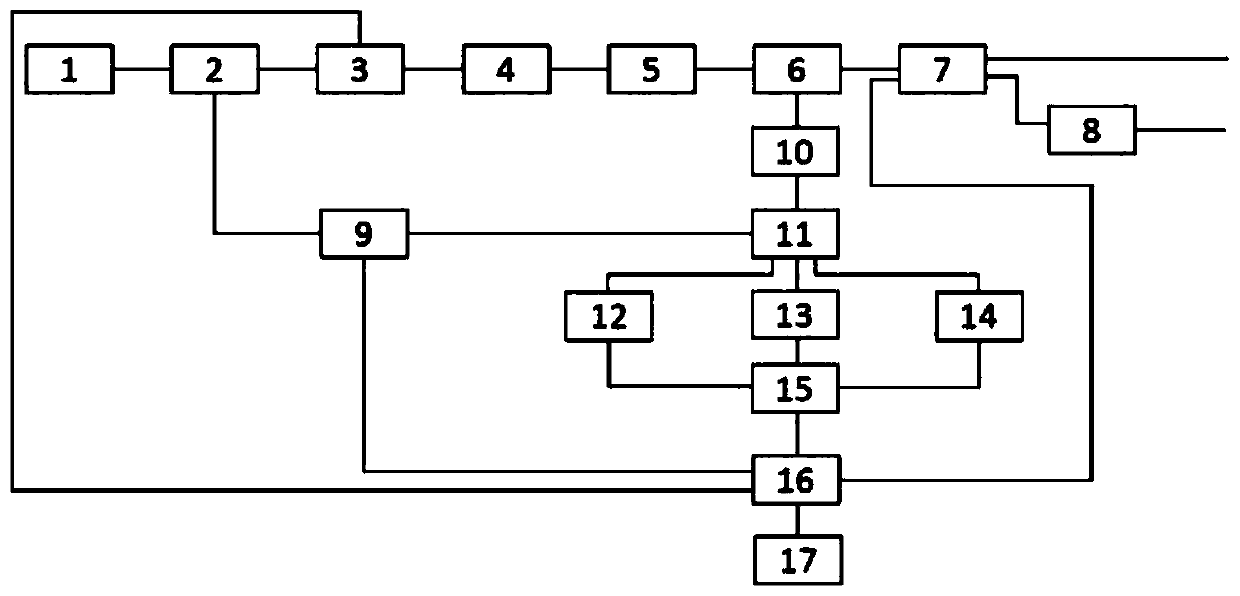

[0023] A distributed optical fiber acoustic wave and vibration fusion sensing system of the present invention, its structure includes a laser 1, a 1×2 optical fiber coupler 2, an acousto-optic modulator 3, an erbium-doped optical fiber amplifier 4, a first optical fiber filter 5, Optical fiber circulator 6, first optical switch, optical fiber Raman amplifier 8, second optical switch 9, second optical fiber filter 10, 3×3 optical fiber coupler 11, first photodetector 12, second photodetector 13 , the third photodetector 14, data acquisition and processing unit 15, computer 16, host computer software 17;

[0024] The laser 1, the 1×2 fiber coupler 2, the acousto-optic modulator 3, the erbium-doped fiber amplifier 4, the first fiber filter 5, the fiber circulator 6, the first optical switch, and the fiber Raman amplifier 8 pass through a single mode optical fiber, the optical fiber circulator 6, the second optical fiber filter 10, the 3×3 optical fiber coupler 11, the first photo...

Embodiment 2

[0044] Compared with Embodiment 1, the difference is that the laser 1 is a narrow linewidth laser.

[0045] All the other contents are the same as in Example 1.

Embodiment 3

[0047] Compared with Embodiment 2, the difference is that the power splitting ratio of the 1×2 fiber coupler 2 is 1:99, and the output power ratio of the first output port of the 1×2 fiber coupler 2 is 99. %, the output power ratio of the second output port of the 1×2 fiber coupler 2 is 1%.

[0048] All the other contents are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com