Polyion liquid electrolyte for in-situ photopolymerization without solvent

A technology of polyionic liquids and ionic liquids, applied in the field of polyionic liquid electrolytes, can solve the problems of cumbersome preparation methods and inability to meet room temperature cycles, and achieve the effects of improving ionic conductivity, good application prospects, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

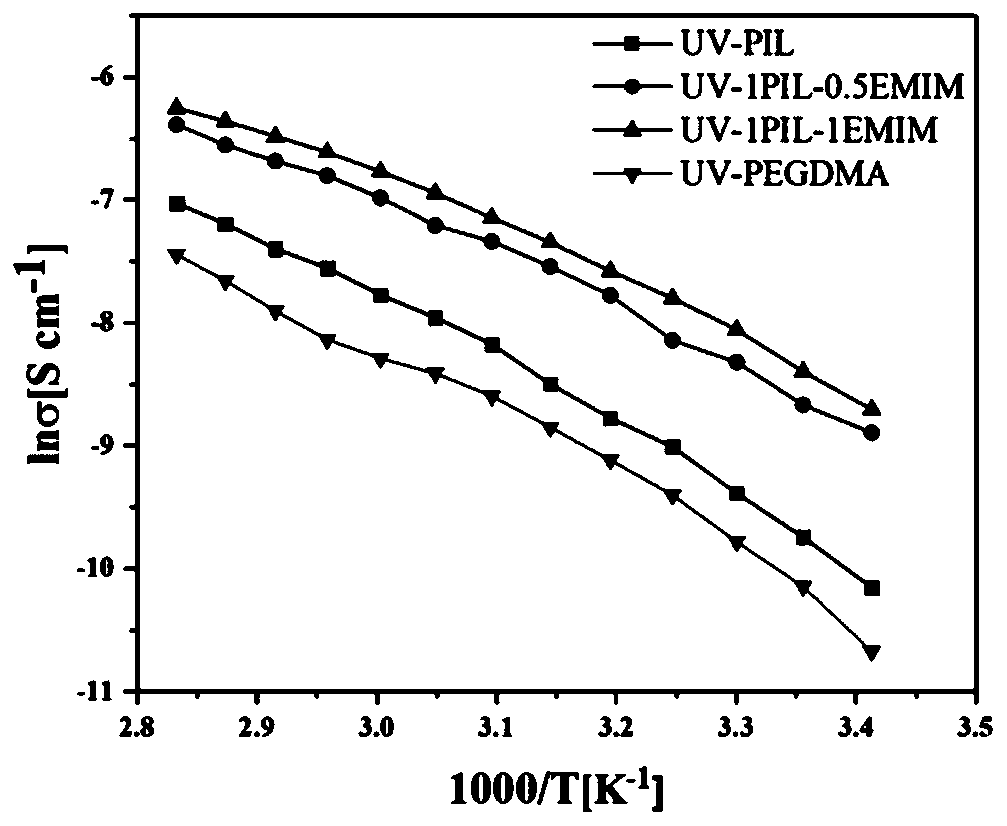

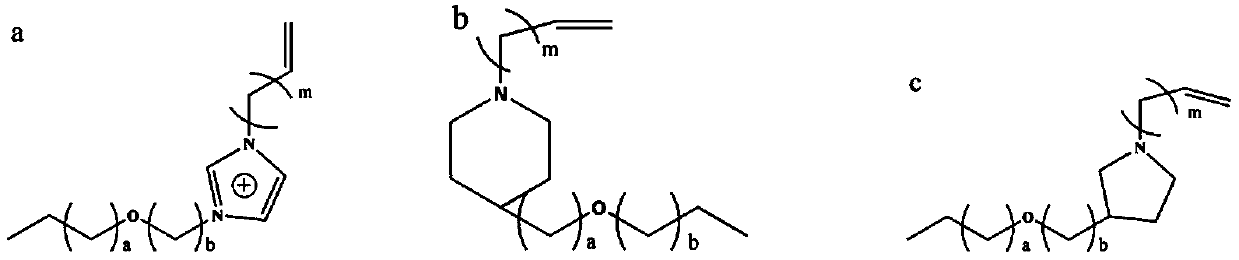

[0023] Take 0.001 mol amount of functionalized polymerizable ionic liquid monomer, add 0.0005 mol PEGDMA, and at the same time add photoinitiator with 5% mass fraction of the total reactive monomer, and add 1-B according to the molar ratio of the total reactive monomer 1:1 Ethyl-3-methylimidazole bistrifluoromethanesulfonimide ([Emim][TFSI]) plasticizer was stirred at room temperature for 6 hours and mixed thoroughly, and then lithium salt was added according to the molar ratio of the total amount of reacted monomers of 1:0.2 LiTFSI, continue to stir for 3 hours to fully mix into a clear solution, use a spatula to evenly coat the viscous solution on a flat polytetrafluoroethylene plate, irradiate with UV light for 60 minutes, perform light polymerization reaction, and finally obtain a cured polyion Liquid electrolyte, and finally cut the polymer electrolyte film into a 16mm diameter disc film for storage and further testing.

Embodiment 2

[0025] Take 0.001 mol amount of functionalized polymerizable ionic liquid monomer, add 0.0005 mol PEGDMA, and at the same time add photoinitiator with 5% mass fraction of the total reactive monomer, and add 1-B according to the molar ratio of the total reactive monomer 1:0.75 Ethyl-3-methylimidazole bistrifluoromethanesulfonimide ([Emim][TFSI]) plasticizer was stirred at room temperature for 6 hours and mixed thoroughly, and then lithium salt was added according to the molar ratio of the total amount of reacted monomers of 1:0.2 LiTFSI, continue to stir for 3 hours to fully mix into a clear solution, use a spatula to evenly coat the viscous solution on a flat polytetrafluoroethylene plate, irradiate with UV light for 60 minutes, perform light polymerization reaction, and finally obtain a cured polyion Liquid electrolyte, and finally cut the polymer electrolyte film into a 16mm diameter disc film for storage and further testing.

Embodiment 3

[0027] Take 0.001 mol amount of functionalized polymerizable ionic liquid monomer, add 0.0005 mol PEGDMA, and add photoinitiator with 5% mass fraction of total reactive monomer at the same time, and add 1-B according to the molar ratio of total reactive monomer 1:0.5 Ethyl-3-methylimidazole bistrifluoromethanesulfonimide ([Emim][TFSI]) plasticizer was stirred at room temperature for 6 hours and mixed thoroughly, and then lithium salt was added according to the molar ratio of the total amount of reacted monomers of 1:0.2 LiTFSI, continue to stir for 3 hours to fully mix into a clear solution, use a spatula to evenly coat the viscous solution on a flat polytetrafluoroethylene plate, irradiate with UV light for 60 minutes, perform light polymerization reaction, and finally obtain a cured polyion Liquid electrolyte, and finally cut the polymer electrolyte film into a 16mm diameter disc film for storage and further testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com