Methods and assemblies using flourine containing and inert gasses for plasma flood gun (PFG) operation

A technology of inert gas and fluorine-containing gas, applied in the direction of plasma, discharge tube ion gun, electrical components, etc., can solve the problems of reducing the yield of ion implantation system and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

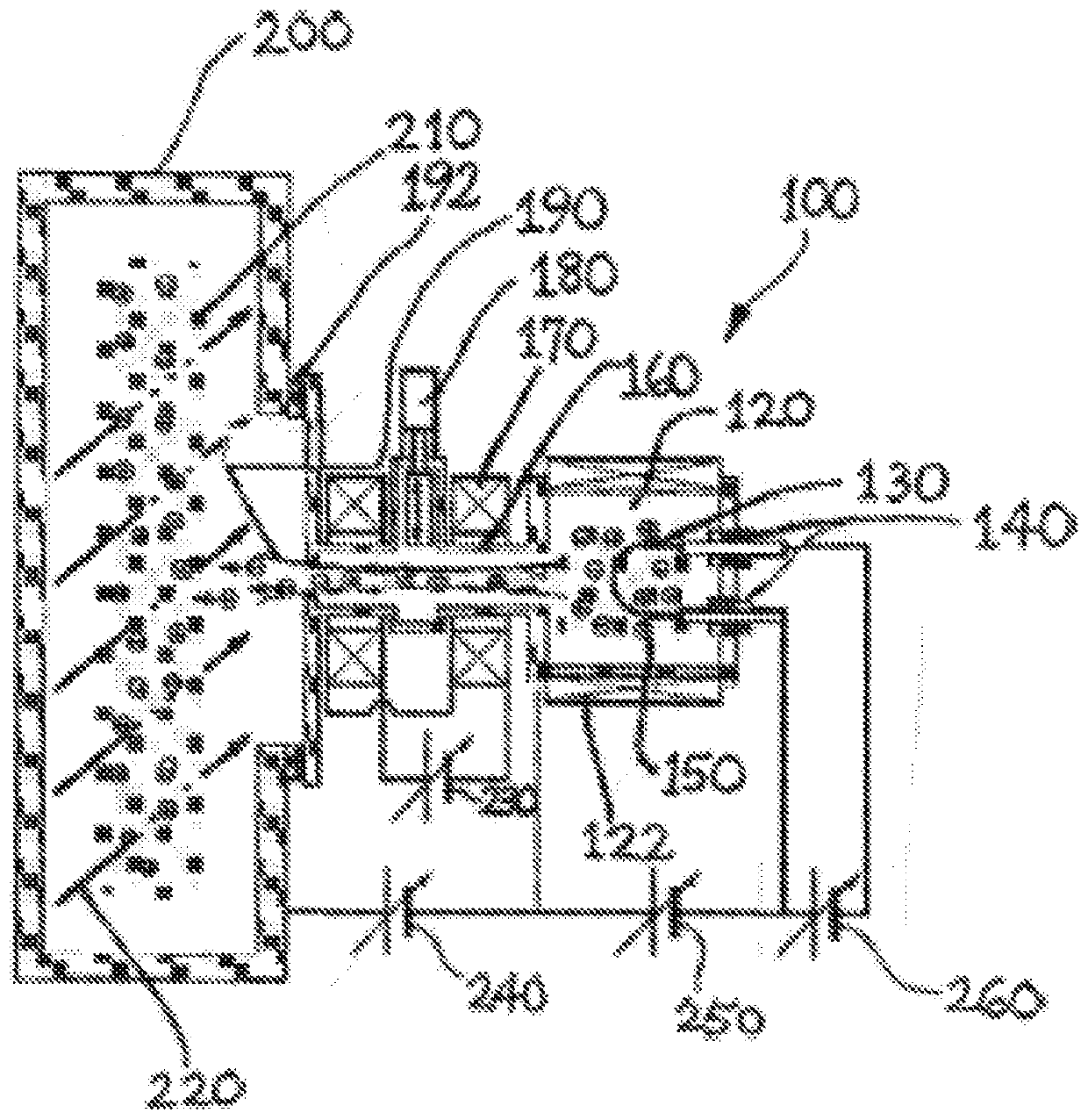

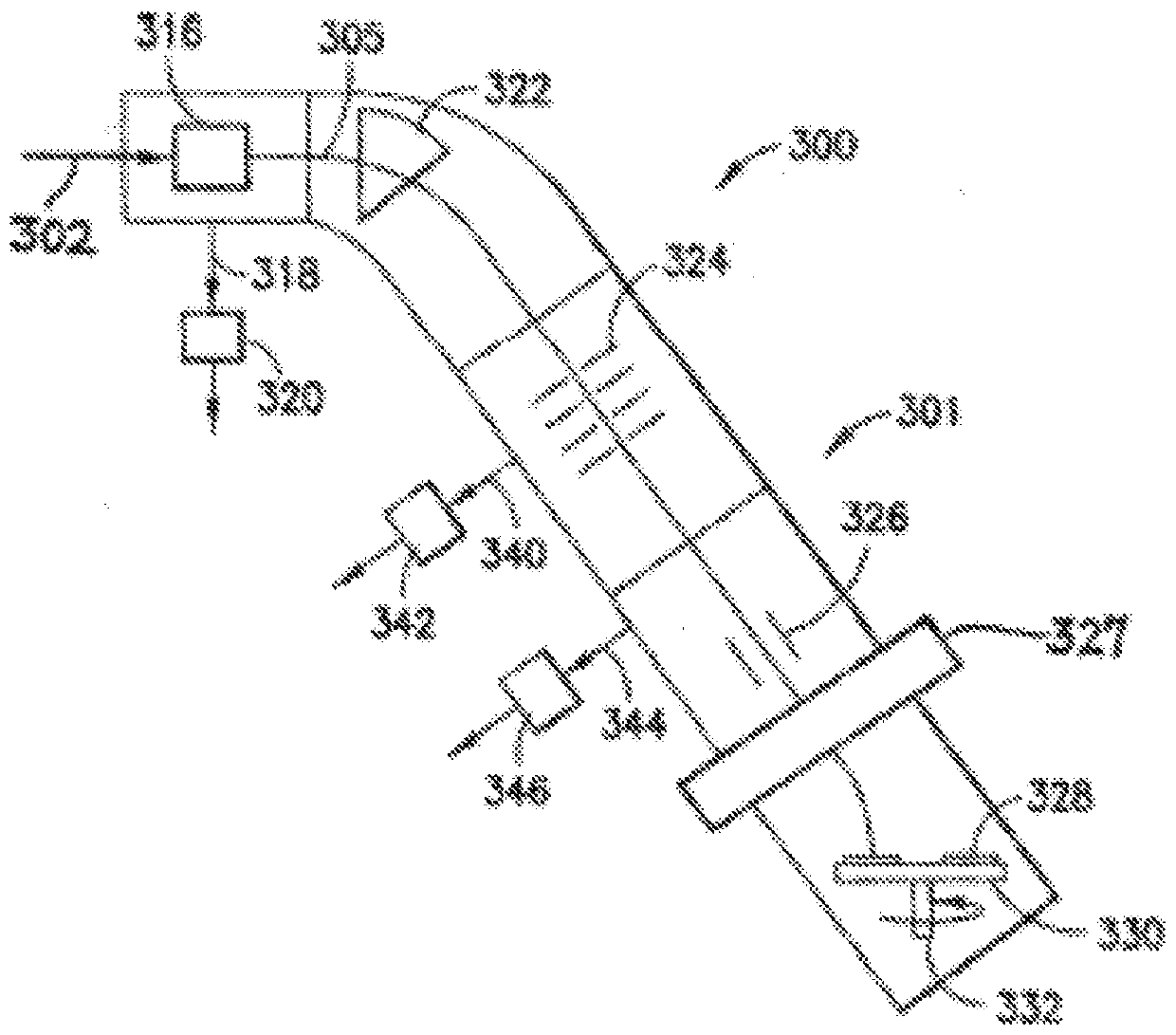

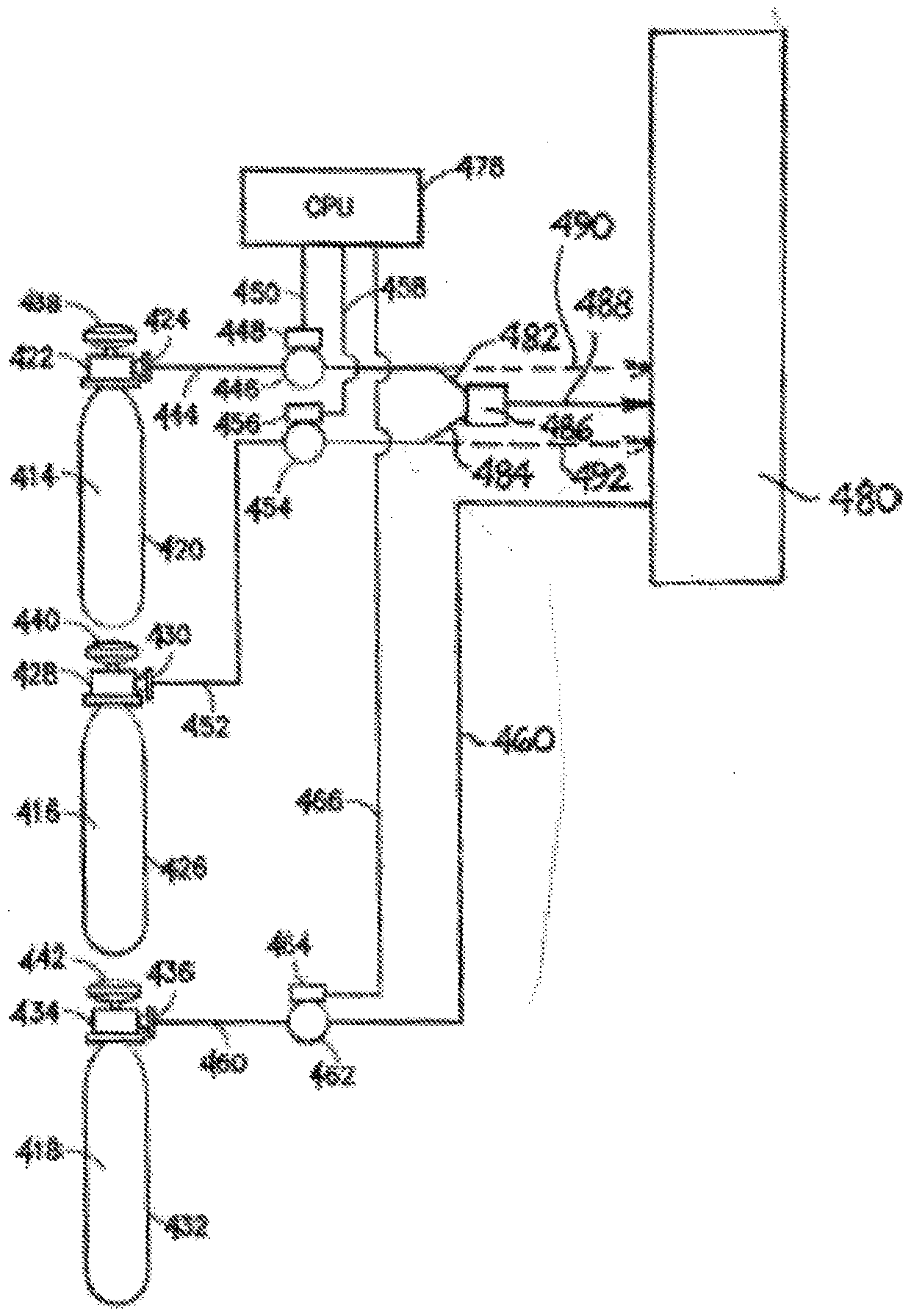

Image

Examples

example 1

[0086] Beam test using Xe gas

[0087] A Bernas ion source with a graphite arc chamber was used. The ion beam conditions are as follows: arc voltage: 50V; arc current: 0.75A; extraction voltage: 20kV; suppression voltage: 3kV. The inert gas used was argon, which flowed into the arc chamber at a rate of 1 sccm or 1.5 sccm. Fluorine-containing gas is a 2% gas mixture (Ar+NF 3 ) using NF 3 , corresponding to a flow rate of 0.021 sccm (1 sccm Ar flow) or 0.031 sccm (1.5 sccm Ar flow). The arc chamber was operated under the gas flow for a total of 11 hours and the source was checked after the operating period and the filament weight was measured and the results are shown in Table 1.

[0088] Table 1

[0089] source# Argon (sccm) NF3(%) Filament Weight Change (g) 1 1 0 -0.037 2 1 2% -0.021 3 1.5 0 -0.030 4 1.5 2% -0.006

[0090] All filament weight changes were negative relative to filament weight loss. When fluorine gas NF is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com