Method for manufacturing filled container, and filled container

A manufacturing method and container technology, which are applied to the manufacture of filled containers and the field of filled containers, can solve problems such as lowering the yield of products, and achieve the effects of preventing mixing and suppressing the reduction of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

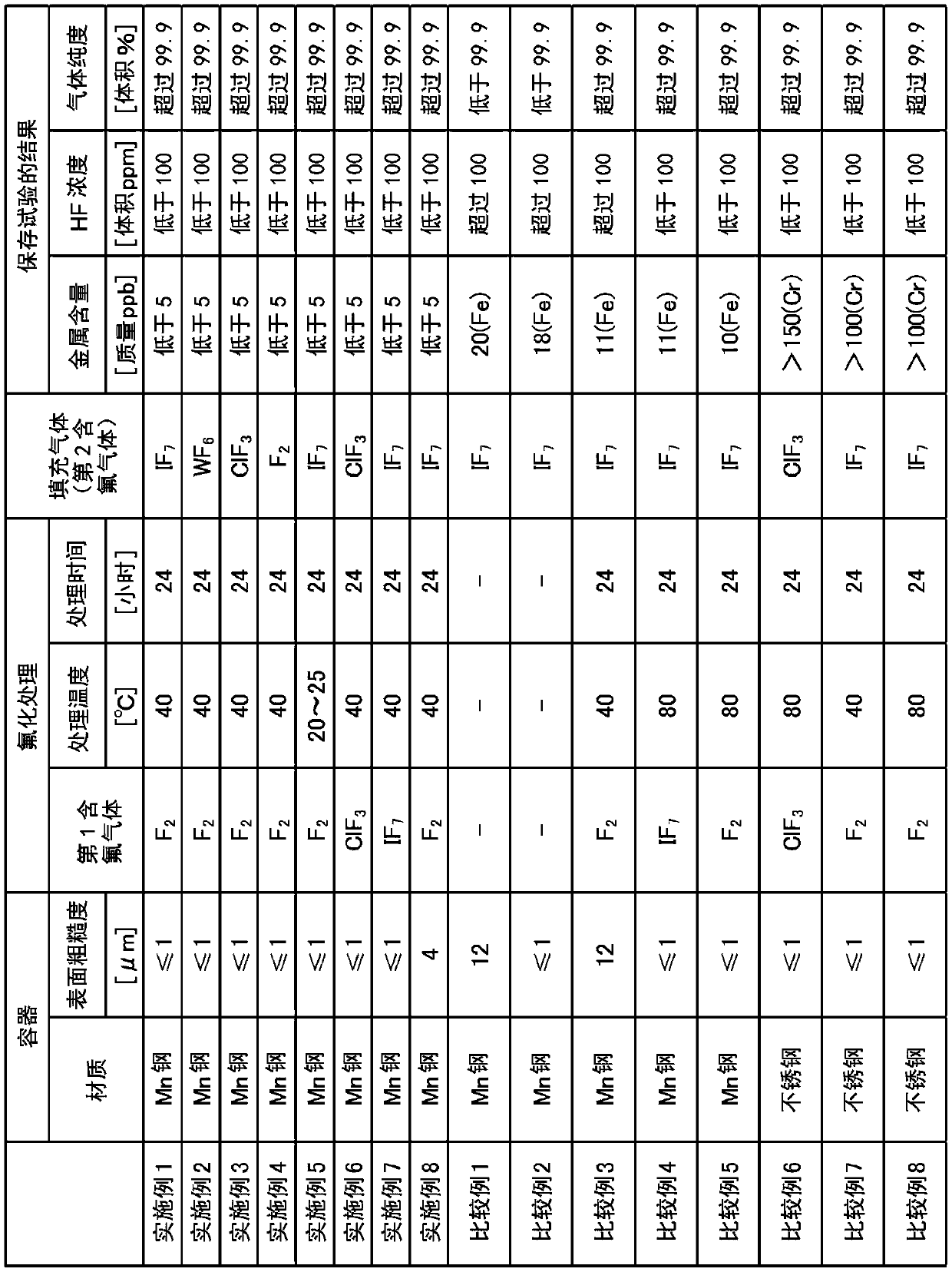

Examples

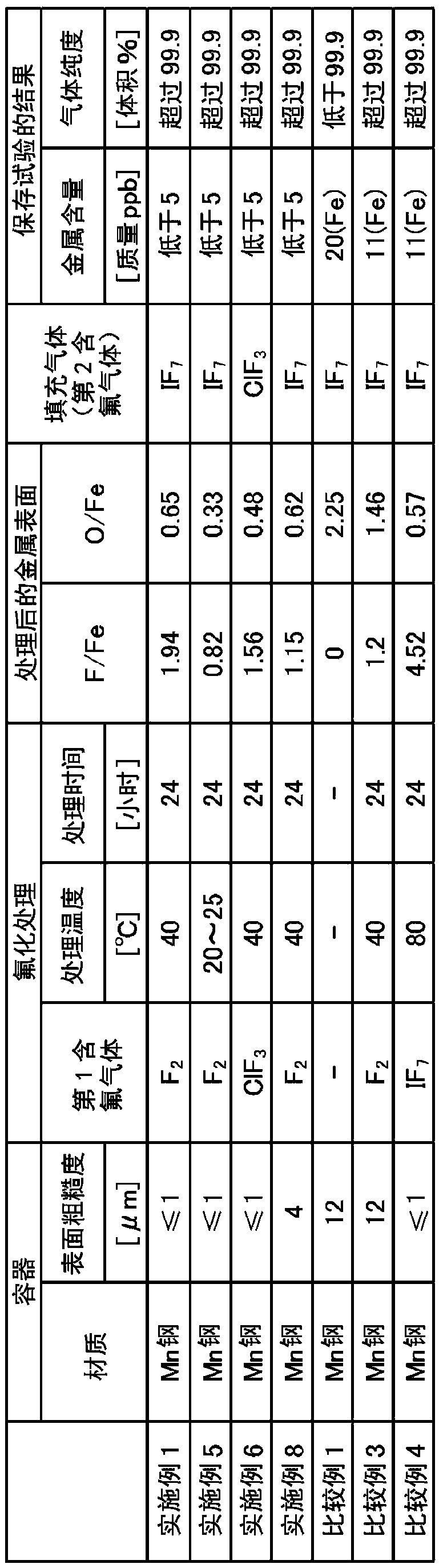

Embodiment 1

[0073] The inner surface of a 3.4L gas cylinder made of manganese steel (code STH12, containing Mn: 1.35-1.70% by mass, C: 0.30-0.41% by mass, and Si, P, and S) was polished by electropolishing. Use a contact surface roughness tester and an atomic force microscope (AFM) to measure the test piece (cut the container into a 20mm x 20mm metal piece) treated under the same grinding conditions to evaluate the surface roughness of the ground inner surface . As a result, the surface roughness R max 1 μm or less.

[0074] After that, at 40°C, F as the first fluorine-containing gas is sealed under atmospheric pressure without dilution 2 Gas for 24 hours, after fluorinating the inner surface, replace it with helium.

[0075] The composition of the inner surface of the gas cylinder was evaluated as follows: The aforementioned test piece treated under the same conditions was evaluated with an X-ray photoelectron spectrometer. As a result, F / Fe was 1.94 and O / Fe was 0.65.

[0076] In t...

Embodiment 2

[0078] Changed the second fluorine-containing gas to WF 6 Gas was carried out in the same manner as in Example 1 except for that. WF after storage 6 The contents of Fe, Mn, Cr, and Ni in the gas were all less than 5 mass ppb, and the purity of the gas exceeded 99.9% by volume, which was unchanged from before storage. The concentration of HF is below 100 ppm by volume.

Embodiment 3

[0080] Change the second fluorine-containing gas to ClF 3 Gas was carried out in the same manner as in Example 1 except for that. ClF after storage 3 The contents of Fe, Mn, Cr, and Ni in the gas were all less than 5 mass ppb, and the purity of the gas exceeded 99.9% by volume, which was unchanged from before storage. The concentration of HF is below 100 ppm by volume.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com