Fermented dietary fiber feed raw material and preparation method thereof

A technology of feed raw materials and dietary fiber, applied in animal feed, animal feed, methods based on microorganisms, etc., can solve problems such as difficult to achieve the expected purpose, unstable effect, etc., to reduce flatulence, improve palatability, and improve color and smell Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

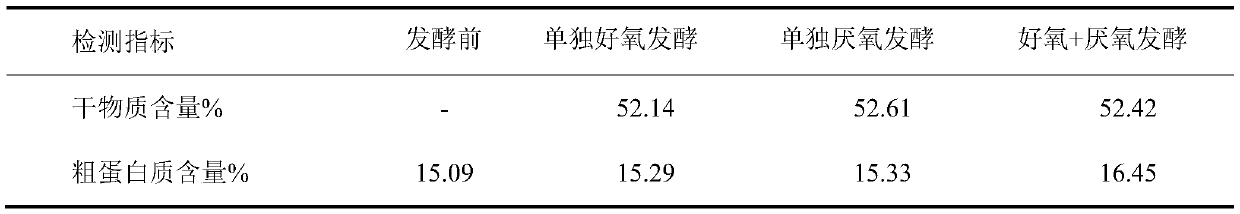

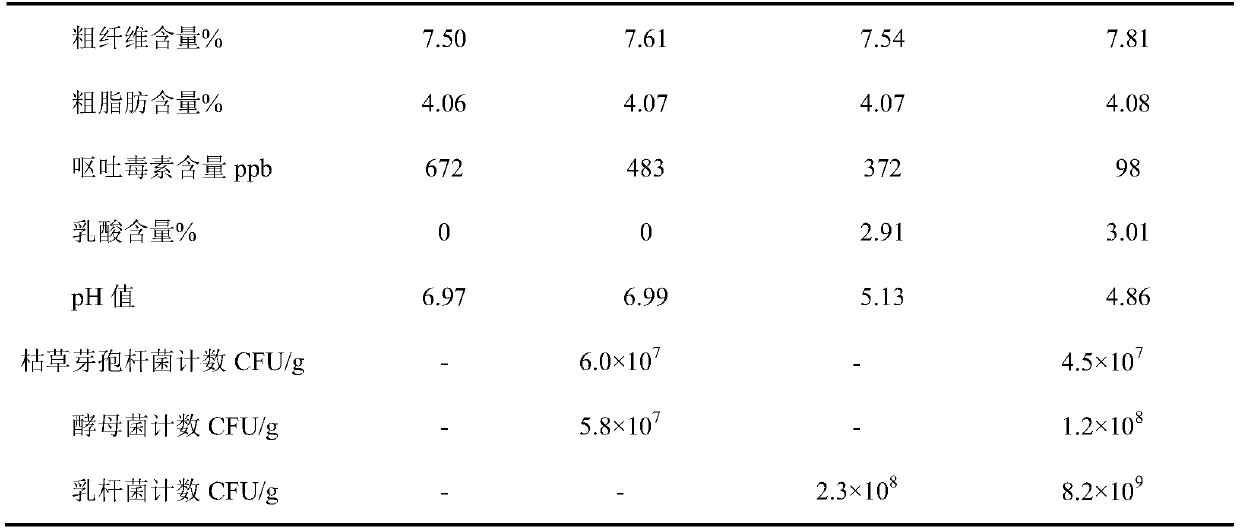

Examples

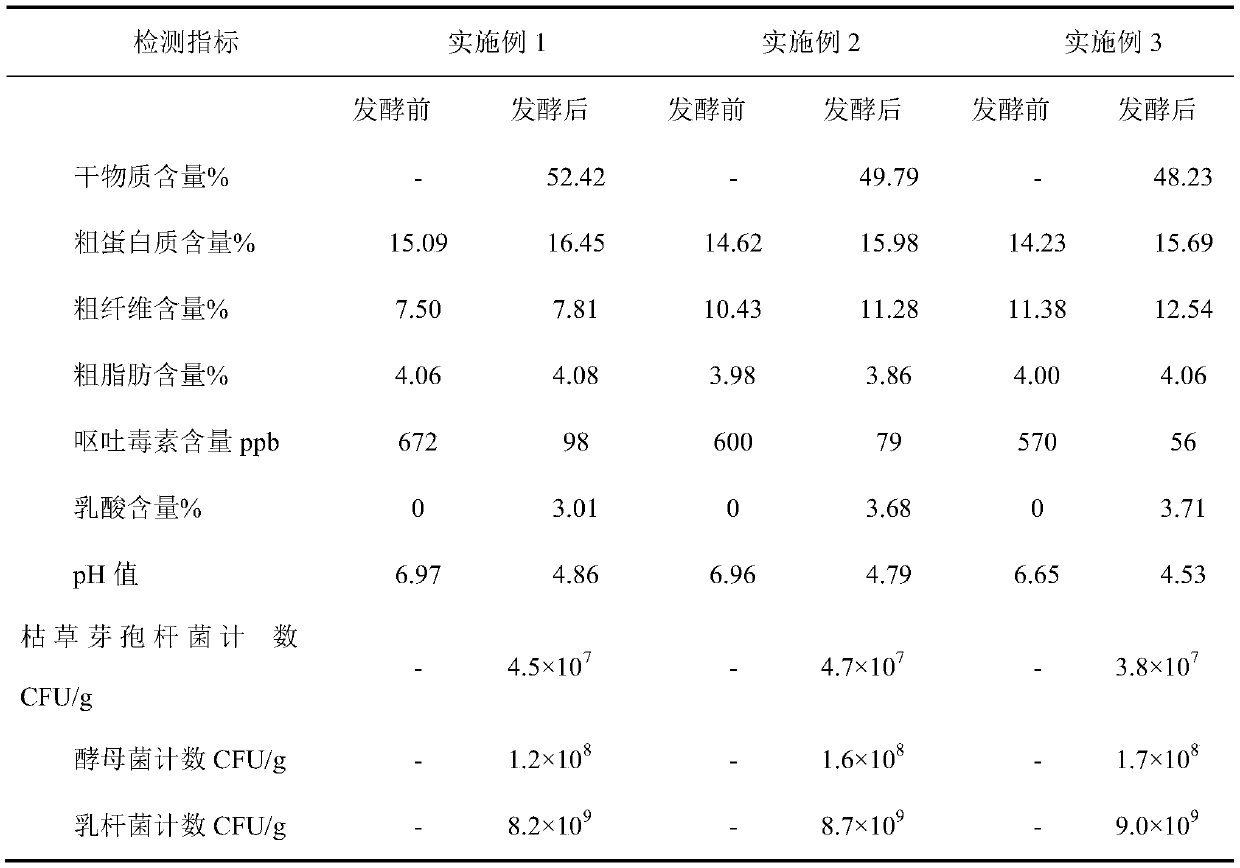

Embodiment 1

[0027] The fermented dietary fiber feed raw material of the present invention comprises the following components by weight: 60 parts of fermentation substrate, 40 parts of bacterial liquid; The concentration of viable bacilli is 1.5×10 8 CFU / ml, the concentration of live yeast cells is 1.5×10 8 CFU / ml, Lactobacillus delbrueckii viable count concentration is 1.5×10 8 CFU / ml, the concentration of viable Lactobacillus plantarum is 1.5×10 8 CFU / ml, described live bacteria is placed in the normal temperature nutrient solution that contains the glucose of 2% by weight, the sodium chloride of 0.9% by weight;

[0028] The preparation method of fermented dietary fiber feed raw material of the present invention comprises the steps:

[0029] 1) Raw material crushing and sterilization: prepare wheat bran and crush the wheat bran, pass the crushed wheat bran through a 20-mesh sieve to obtain the fermentation substrate raw material powder, take 4500g of the fermentation substrate raw mat...

Embodiment 2

[0039] The fermented dietary fiber feed raw material of the present invention comprises the following weight components: 57 parts of fermentation substrate, 43 parts of bacterial liquid; the fermentation substrate is a plant material with a mass content of crude fiber greater than 5%, and in the bacterial liquid, Bacillus subtilis The concentration of viable bacilli is 1.5×10 8 CFU / ml, the concentration of live yeast cells is 1.5×10 8 CFU / ml, Lactobacillus delbrueckii viable count concentration is 1.5×10 8 CFU / ml, the concentration of viable Lactobacillus plantarum is 1.5×10 8 CFU / ml, described viable bacteria is placed in the normal temperature nutrient solution that contains the glucose of 2% by weight, the sodium chloride of 0.9% by weight;

[0040] The preparation method of fermented dietary fiber feed raw material of the present invention comprises the steps:

[0041] 1) Grinding and sterilization of raw materials: Prepare wheat bran and soybean hulls and pulverize the...

Embodiment 3

[0048] The fermented dietary fiber feed raw material of the present invention comprises the following components by weight: 55 parts of fermentation substrate, 45 parts of bacterial liquid; The concentration of viable bacilli is 1.5×10 8 CFU / ml, the concentration of live yeast cells is 1.5×10 8 CFU / ml, Lactobacillus delbrueckii viable count concentration is 1.5×10 8 CFU / ml, the viable count concentration of Lactobacillus plantarum is 1.5×10 8 CFU / ml, the bacterium is placed in the nutrient solution containing 2% glucose by weight and 0.9% sodium chloride by weight in the solution;

[0049] The preparation method of fermented dietary fiber feed raw material of the present invention comprises the steps:

[0050] 1) Grinding and sterilization of raw materials: prepare wheat bran, soybean hulls, and citrus residues and crush the wheat bran, soybean hulls, and citrus residues, and pass the crushed wheat bran, soybean hulls, and citrus residues through a 20-mesh sieve to obtain w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com