Polypropylene nucleating and cooling bifunctional master batch and preparation method and application thereof

A dual-function, polypropylene technology, applied in the field of melt blown, to achieve the effect of promoting dispersion, promoting refinement, and achieving uniform degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] Further preferably, the preparation method of the foam carrier of the present invention comprises the following steps:

[0061] After heating the polyolefin and the nucleating agent to 150-160°C and mixing, inject the foaming agent at a pressure of 15-20 MPa, mix, and extrude from the mouth film, the pressure of the mouth film drops to 15-20 MPa, and the foam is obtained. Foam carrier; the porosity of the foam carrier is 70-80%

[0062] The pressure of the orifice will be the pressure that drops as the premix passes through the orifice.

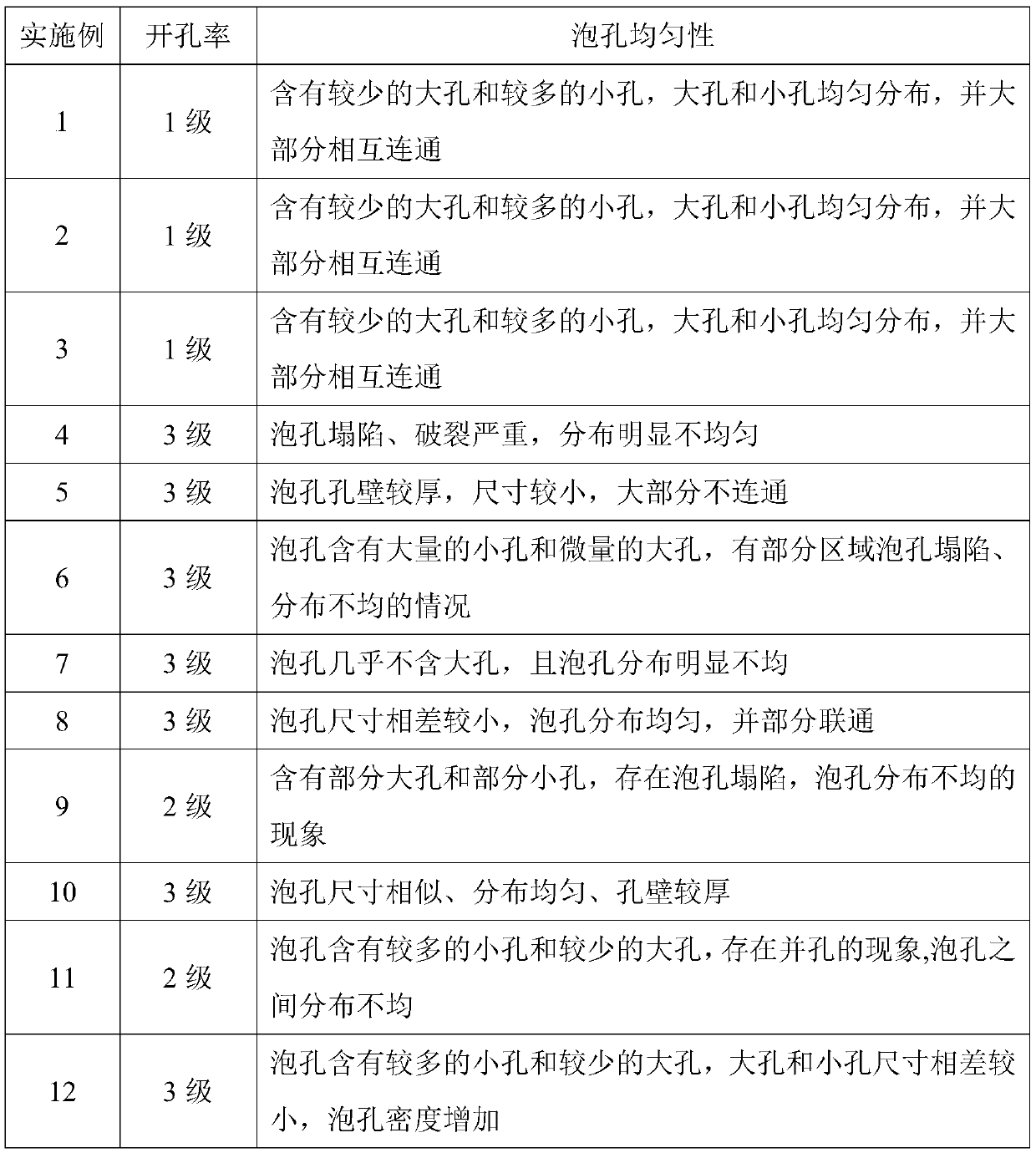

[0063] The cells in the foamed material include open cells and closed cells. Open cells are cells whose walls are not completely closed and are directly or indirectly connected to other cells. Closed cells are closed cells that are not the same as other cells. The open porosity rate is the volume percentage of open pores, which can be obtained by testing methods well known in the art, such as ASTM D2856-94.

[0064] The applicant fou...

Embodiment 1

[0096] This example provides a kind of bifunctional masterbatch, the preparation raw material of described bifunctional masterbatch includes foaming carrier, nucleating agent and peroxide; The weight percentage of described nucleating agent accounting for bifunctional masterbatch is 1.25wt%; The peroxide accounts for 10wt% by weight of the bifunctional masterbatch; the raw materials for the preparation of the foam carrier include polyolefins and carbon dioxide, and the polyolefins include styrene-ethylene-butylene-styrene copolymers and polyolefins. Propylene, the weight ratio is 0.2:1, the weight percentage of the carbon dioxide in the polyolefin is 8wt%; the preparation method of the foam carrier includes the following steps: melt mixing: heat the polyolefin and the nucleating agent to 160°C and mix , inject carbon dioxide at a pressure of 15 MPa, mix, and extrude from the mouth film, the pressure drop of the mouth film is 15 MPa, to obtain a foamed carrier.

[0097] The pol...

Embodiment 2

[0106] This example provides a kind of bifunctional masterbatch, the preparation raw material of described bifunctional masterbatch includes foaming carrier, nucleating agent and peroxide; The weight percentage of described nucleating agent accounting for bifunctional masterbatch is 1.25wt%; The peroxide accounts for 10wt% by weight of the bifunctional masterbatch; the raw materials for the preparation of the foam carrier include polyolefins and carbon dioxide, and the polyolefins include styrene-ethylene-butylene-styrene copolymers and polyolefins. Propylene, the weight ratio is 0.3:1, the weight percentage of the carbon dioxide in the polyolefin is 10wt%; the preparation method of the foam carrier includes the following steps: melt mixing: heat the polyolefin and the nucleating agent to 150°C and mix , inject carbon dioxide at a pressure of 20 MPa, mix, and extrude from the mouth film, the pressure drop of the mouth film is 20 MPa, to obtain a foamed carrier.

[0107] The po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com