Water-borne polyurethane foam layer for synthetic leather and preparation method for water-borne polyurethane foam layer

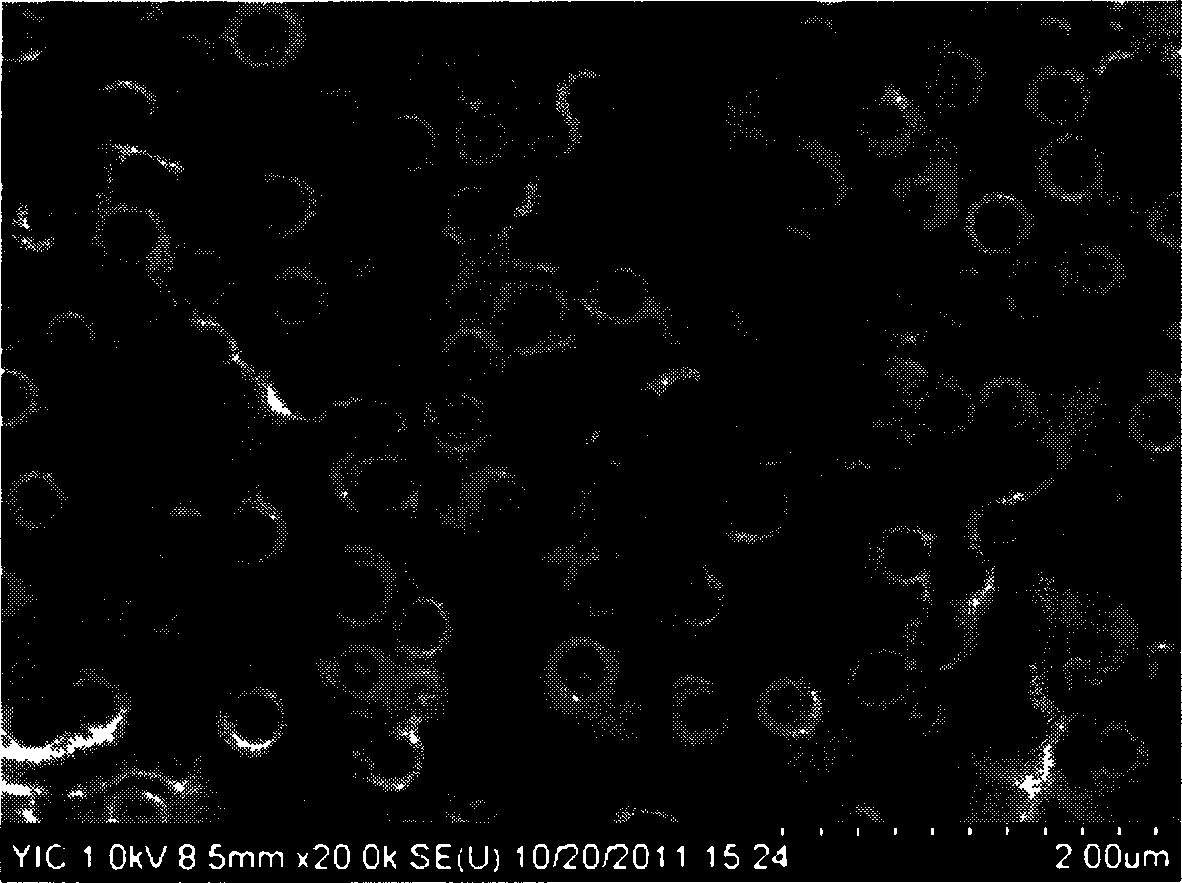

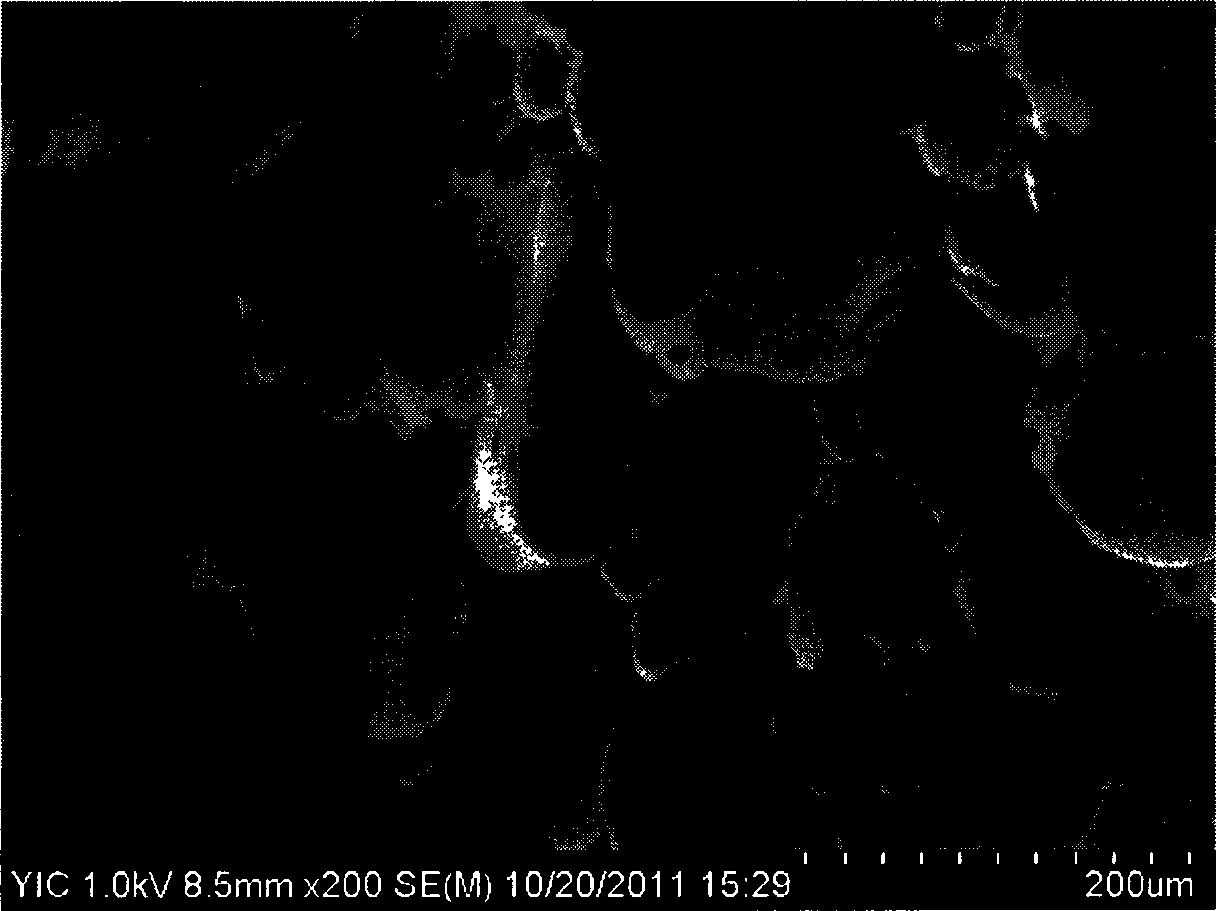

A water-based polyurethane and foam layer technology, used in polyurea/polyurethane coatings, coatings, textiles and papermaking, etc., can solve the problems of the appearance of the foam layer, the mechanical strength is not satisfactory, the cells of the foam layer are easily uneven, and the foam bursts. , fusion and other issues, to achieve the effect of not easy to be affected by the external environment, stable and uniform cells, and uniform cell size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The formula of water-based polyurethane foam layer slurry for synthetic leather is:

[0045] Water-based polyurethane emulsion: 89.8 parts

[0046] Organic resin hollow microsphere emulsion: 5 parts, the organic resin hollow microsphere used is Dow Chemical Le Coolpad TM Youchuang E, the effective solid content is 30wt%

[0047] Cross-linking agent: 1 part

[0048] Emulsifier: 2 parts

[0049] Leveling agent: 0.2 parts

[0050] Colorant: 1 part

[0051] Thickener: 1 part

Embodiment 2

[0053] The formula of water-based polyurethane foam layer slurry for synthetic leather is:

[0054] Water-based polyurethane emulsion: 71 parts

[0055] Organic resin hollow microsphere emulsion: 17 parts, the effective solid content is 30wt%, and its shell shell structure is the copolymer of methyl methacrylate and butyl methacrylate, and its preparation method refers to patent US4427836A, embodiment 1 and Example 6

[0056] Water: 5.8 parts

[0057] Cross-linking agent: 1 part

[0058] Emulsifier: 2 parts

[0059] Leveling agent: 0.2 parts

[0060] Colorant: 1 part

[0061] Thickener: 2 parts

Embodiment 3

[0063] The formula of water-based polyurethane foam layer slurry for synthetic leather is:

[0064] Water-based polyurethane emulsion: 62.3 parts

[0065] Organic resin hollow microsphere emulsion: 31 parts, the effective solid content is 30wt%, and the organic resin hollow microsphere shell used is a polyurethane polymer, which is prepared by the following method: 160g polyethylene glycol (molecular weight 2000) and 20g isofor The ketone diisocyanate is prepolymerized at 80°C to obtain a prepolymerized polymer. Dissolve the obtained prepolymer in 220g of cyclohexane, add 1500g of water to quickly disperse, and obtain droplets with the required particle size, then add 9g of isophoronediamine, raise the temperature to 50°C, and the isophoronediamine Carry out curing reaction with the remaining isocyanate group in the prepolymer at the two-phase interface to obtain microcapsule particles, and remove the organic solvent under reduced pressure to obtain the final product.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com