Long-lasting antistatic pearl cotton epe and preparation method thereof

An antistatic and pearl cotton technology, which is applied in the field of pearl cotton, can solve the problems of resin mixing ratio, difficult measurement of talcum powder, and increased process defect rate, etc., and achieve stable antistatic value, excellent dispersibility and surface activity, excellent antistatic The effect of electrostatic capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

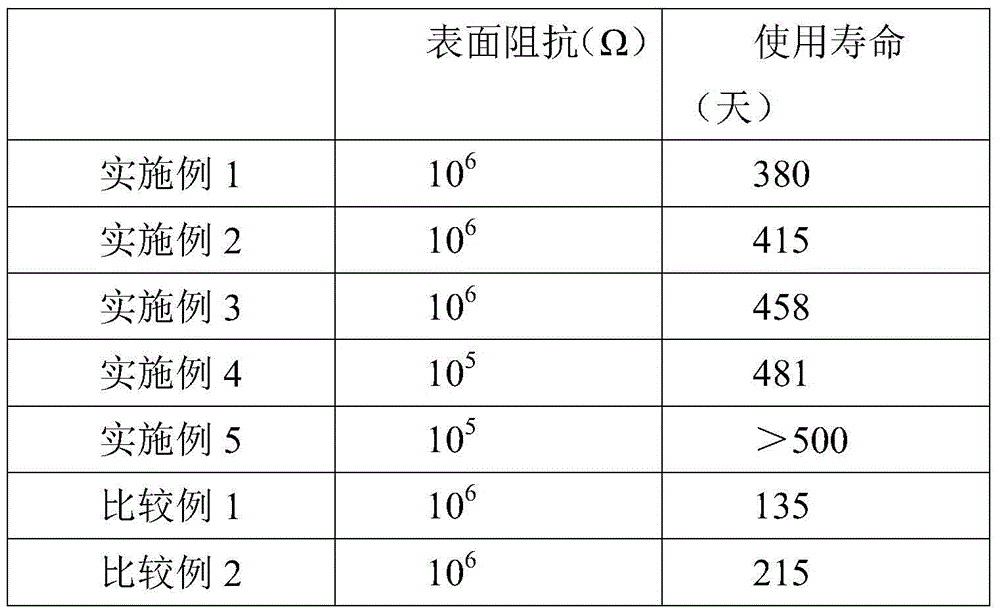

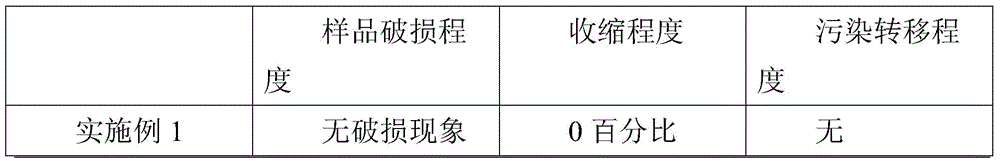

Examples

Embodiment 1

[0019] In the embodiment of the present invention, the long-lasting antistatic pearl cotton EPE is composed of the following raw materials in parts by weight: 133 parts of polyethylene resin, 25 parts of sodium lignosulfonate, 11 parts of zirconium dioxide, 1 part of neodymium oxide, tetra-titanate 4 parts of butyl ester, 10 parts of cyclohexane.

[0020] The preparation method of long-lasting antistatic pearl cotton EPE comprises the steps:

[0021] 1) Put tetrabutyl titanate into the reaction kettle, add cyclohexane, seal and stir, raise the temperature to 100°C, keep it at 100°C for 2 hours, cool down to 80°C, then add neodymium oxide, continue to heat at 80°C Stir for 1h; the stirring speed is 100r / min, and the mixed solution A is obtained for later use;

[0022] 2) After mixing sodium lignosulfonate and zirconium dioxide, put them into a pulverizer to pulverize, the particle size is 180-200 mesh, and prepare mixture B for later use;

[0023] 3) Add polyethylene resin an...

Embodiment 2

[0026] In the embodiment of the present invention, the long-lasting antistatic pearl cotton EPE is composed of the following raw materials in parts by weight: 142 parts of polyethylene resin, 36 parts of sodium lignosulfonate, 16 parts of zirconium dioxide, 5 parts of neodymium oxide, tetra-titanate 12 parts of butyl ester, 15 parts of cyclohexane.

[0027] The preparation method of long-lasting antistatic pearl cotton EPE comprises the steps:

[0028] 1) Put tetrabutyl titanate into the reaction kettle, add cyclohexane, seal and stir, raise the temperature to 120°C, keep it at 120°C for 1 hour, cool down to 90°C, then add neodymium oxide, continue to heat at 90°C Stir for 0.5h; the stirring speed is 120r / min, and the mixture A is obtained for later use;

[0029] 2) After mixing sodium lignosulfonate and zirconium dioxide, put them into a pulverizer to pulverize, the particle size is 180-200 mesh, and prepare mixture B for later use;

[0030] 3) Add polyethylene resin and mi...

Embodiment 3

[0033] In the embodiment of the present invention, the long-lasting antistatic pearl cotton EPE is composed of the following raw materials in parts by weight: 135 parts of polyethylene resin, 28 parts of sodium lignosulfonate, 13 parts of zirconium dioxide, 2 parts of neodymium oxide, tetra-titanate 8 parts of butyl ester, 12 parts of cyclohexane.

[0034] The preparation method of long-lasting antistatic pearl cotton EPE comprises the steps:

[0035] 1) Put tetrabutyl titanate into the reaction kettle, add cyclohexane, seal and stir, raise the temperature to 105°C, keep it at 105°C for 1.2h, cool down to 82°C, then add neodymium oxide, continue to heat at 82°C Stir down for 0.6h; the stirring speed is 105r / min, and the mixed solution A is obtained for subsequent use;

[0036] 2) After mixing sodium lignosulfonate and zirconium dioxide, put them into a pulverizer to pulverize, the particle size is 180-200 mesh, and prepare mixture B for later use;

[0037] 3) Add polyethylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com