A kind of expandable microsphere foaming agent, its preparation method and foaming material

A technology of expanding microspheres and foaming agents, which is applied in the field of foaming materials, can solve problems such as carbonization of the shell of microsphere foaming agents, negative effects on the performance of foaming matrix, loss of airtightness and controllability of cells, and achieve foaming Pore stability, good controllability of foaming, relatively stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

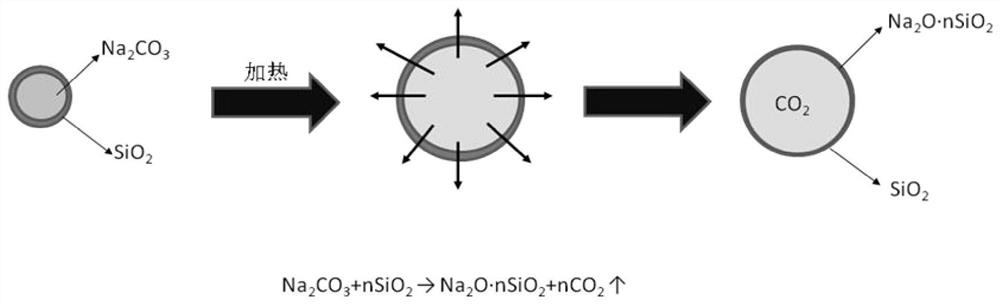

[0026] The application also provides a preparation method of expandable microsphere blowing agent, comprising the following steps:

[0027] A) Sodium carbonate, stabilizing agent and silane coupling agent are dispersed in solution, heating, obtain the sodium carbonate dispersion liquid of silane modification;

[0028] B) reacting the sodium carbonate dispersion and the silicon source under alkaline conditions, and obtaining an expandable microsphere foaming agent after vacuum drying.

[0029] In the process of preparing the expandable microsphere foaming agent, sodium carbonate, a stabilizer and a silane coupling agent are first dispersed in a solution and heated to obtain a silane-modified sodium carbonate dispersion. The above-mentioned sodium carbonate is also called soda ash and soda, and is an important chemical raw material with a melting point of 851°C and a decomposition temperature of 1744°C; the sodium carbonate used in the present invention is Class I that meets the...

Embodiment 1

[0038] Embodiment 1 provides a kind of inorganic expandable microsphere blowing agent, detailed preparation steps are as follows:

[0039] Dissolve 10 mg of sodium alginate in 5 mL of deionized water in a beaker, then take the beaker and weigh 1.5 g of sodium carbonate and disperse it in 100 mL of absolute ethanol, pour the above solution into a three-necked flask in a water bath at 50°C and stir, and add 2 mL of γ -Aminopropyltriethoxysilane, then magnetically stirred for 60 minutes to obtain a silane-modified sodium carbonate dispersion; then the three-necked flask was transferred to a normal temperature water bath for stirring at 120 rpm, and a small amount of ammonia water was added to the dispersion with a pipette gun until the pH = 11.5, then slowly add 2mL tetraethyl orthosilicate drop by drop, and stir for 1h; finally, the reaction product is first pickled with dilute hydrochloric acid to remove unreacted sodium carbonate, and then washed repeatedly with absolute ethano...

Embodiment 2

[0042] Embodiment 2 provides a kind of inorganic expandable microsphere foaming agent, detailed preparation steps are as follows:

[0043] Dissolve 10 mg of sodium alginate in 5 mL of deionized water in a beaker, then take the beaker to weigh 5 g of sodium carbonate and disperse it in 100 mL of absolute ethanol, pour the above solution into a three-necked flask in a water bath at 50°C and stir, and add 2 mL of γ- Aminopropyltriethoxysilane, and then magnetically stirred for 60 minutes to obtain a silane-modified sodium carbonate dispersion; then transfer the three-necked flask to a normal temperature water bath at 120rpm to stir, and use a pipette to take a small amount of ammonia water and add it to the dispersion pH = 11.5 , then slowly add 2 mL of tetraethyl orthosilicate drop by drop, and stir for 1 h; finally, the reaction product is first pickled with dilute hydrochloric acid to remove unreacted sodium carbonate, then washed repeatedly with absolute ethanol and deionized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com