Production process of environment-friendly composite pigment

A composite pigment and production process technology, applied in anthracene dyes, organic dyes, inks, etc., can solve the problems of small application range of heat-resistant pigments, low-viscosity storage stability, unfavorable market promotion, etc., to increase solvent resistance and Migration resistance, good fluidity, and the effect of not easy precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

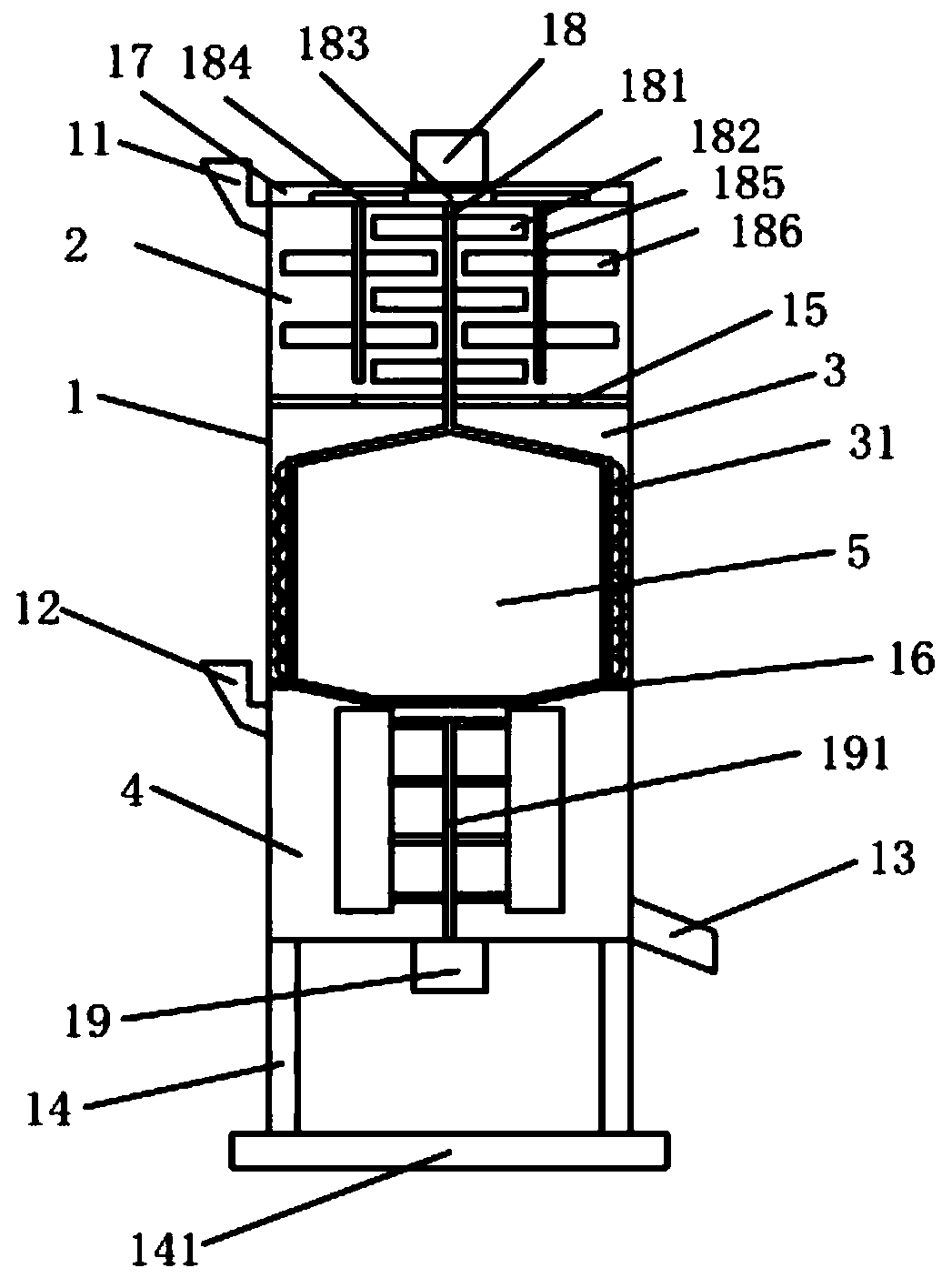

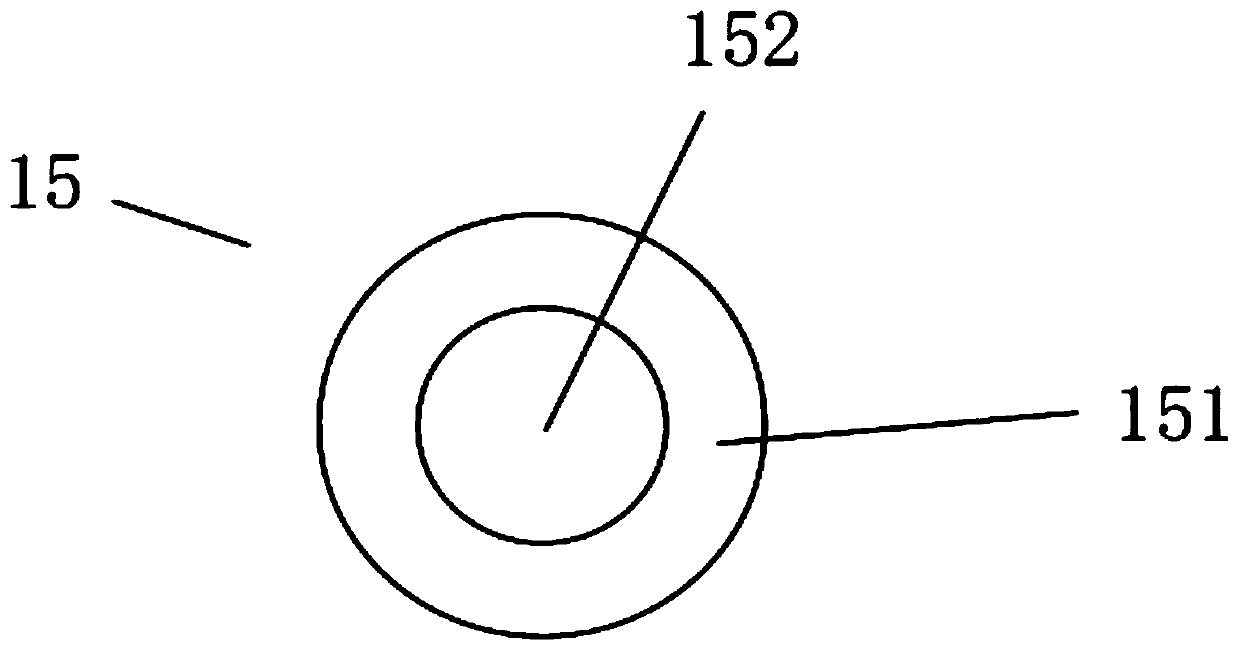

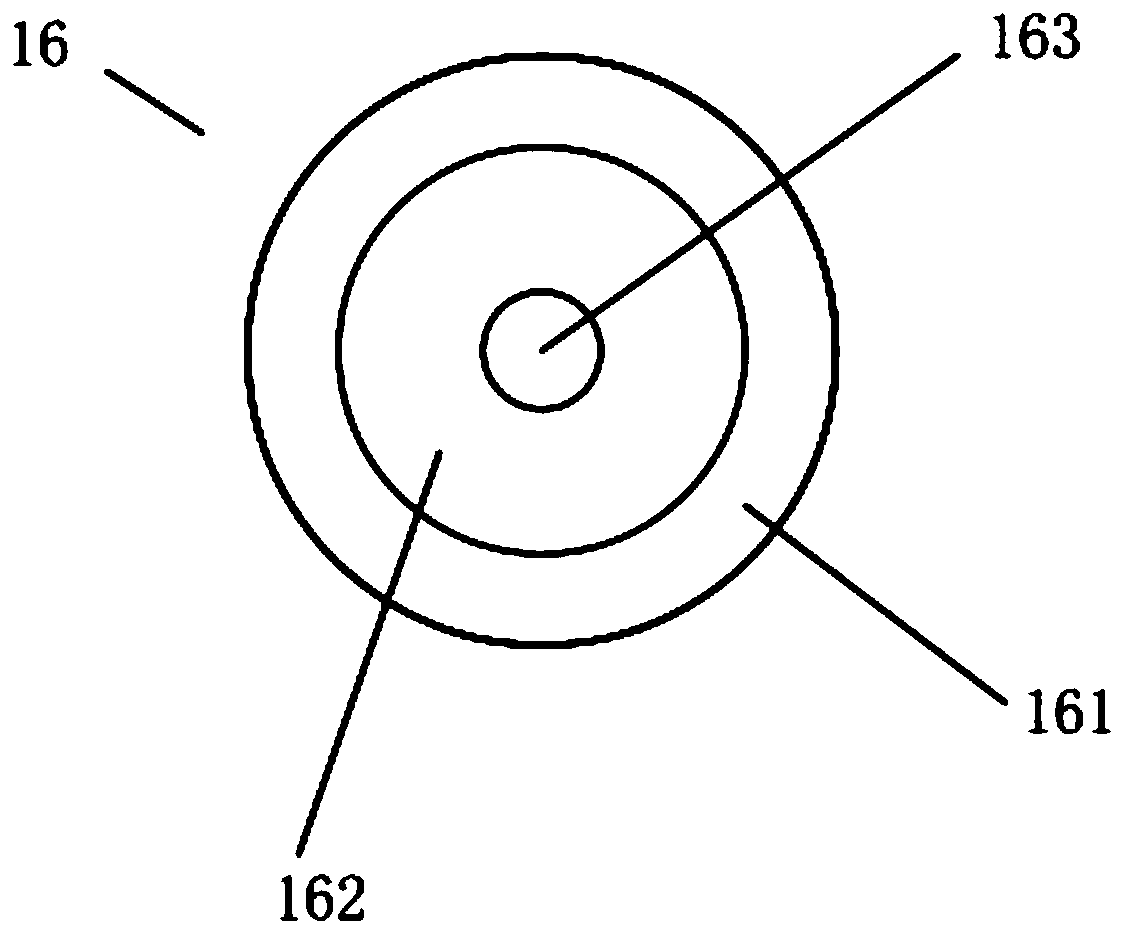

Image

Examples

Embodiment 1

[0049] A production process of an environment-friendly composite pigment. The environment-friendly composite pigment is made of the following raw materials in parts by weight: 20 parts of pigment base, 30 parts of ethanol, 3 parts of CH-M8, 7 parts of glacial acetic acid, and 1.5 parts of glycerol trihydroxy polyether ;

[0050] The concrete steps of the production technology of this environment-friendly composite pigment are as follows:

[0051] Step A1: adding the pigment matrix into an oven, and drying for 5 hours at a temperature of 60° C. to obtain the dried pigment matrix;

[0052] Step A2: Add the dried pigment matrix obtained in step A1 into a grinding disperser, grind for 20 minutes at a speed of 1000 r / min until the particle size of the pigment matrix is 0.05 μm, add ethanol into the grinding disperser, Under the condition of rotating speed of 1500r / min, disperse for 30min to obtain the dispersion liquid;

[0053] Step A3: Add CH-M8 and glacial acetic acid into a...

Embodiment 2

[0061] A production process of an environment-friendly composite pigment. The environment-friendly composite pigment is made of the following raw materials in parts by weight: 40 parts of pigment base, 60 parts of ethanol, 5 parts of CH-M8, 10 parts of glacial acetic acid, and 4 parts of glycerol trihydroxy polyether ;

[0062] The concrete steps of the production technology of this environment-friendly composite pigment are as follows:

[0063] Step A1: Add the pigment matrix into an oven, and dry it for 6 hours at a temperature of 70° C. to obtain the dried pigment matrix;

[0064] Step A2: Add the dried pigment matrix obtained in step A1 into a grinding disperser, grind for 30 minutes at a speed of 1500 r / min, until the particle size of the pigment matrix is 0.1 μm, add ethanol into the grinding disperser, Under the condition of rotating speed of 2000r / min, disperse for 40min to obtain the dispersion liquid;

[0065] Step A3: Add CH-M8 and glacial acetic acid into a sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com