Alloy steel forged brake disc with characteristics of inhibiting friction sparks and manufacturing method of alloy steel forged brake disc

A manufacturing method and technology of alloy steel, applied in the directions of brake discs, friction linings, metal rolling, etc., can solve the problems of complex train operating environment, easy generation of micro-cracks in alloys, poor material bonding performance, etc., and reduce the friction of forgings. The tendency of spark generation, the suppression of friction spark characteristics, the effect of reducing the grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

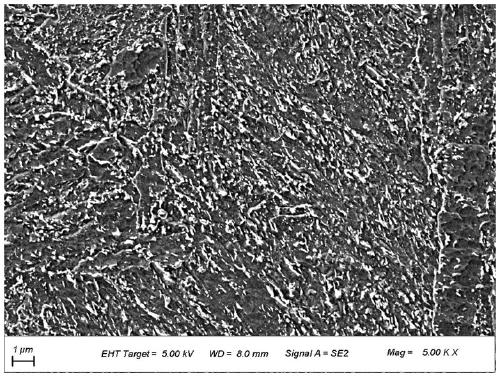

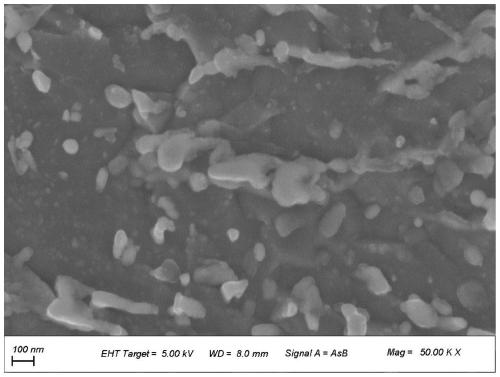

Image

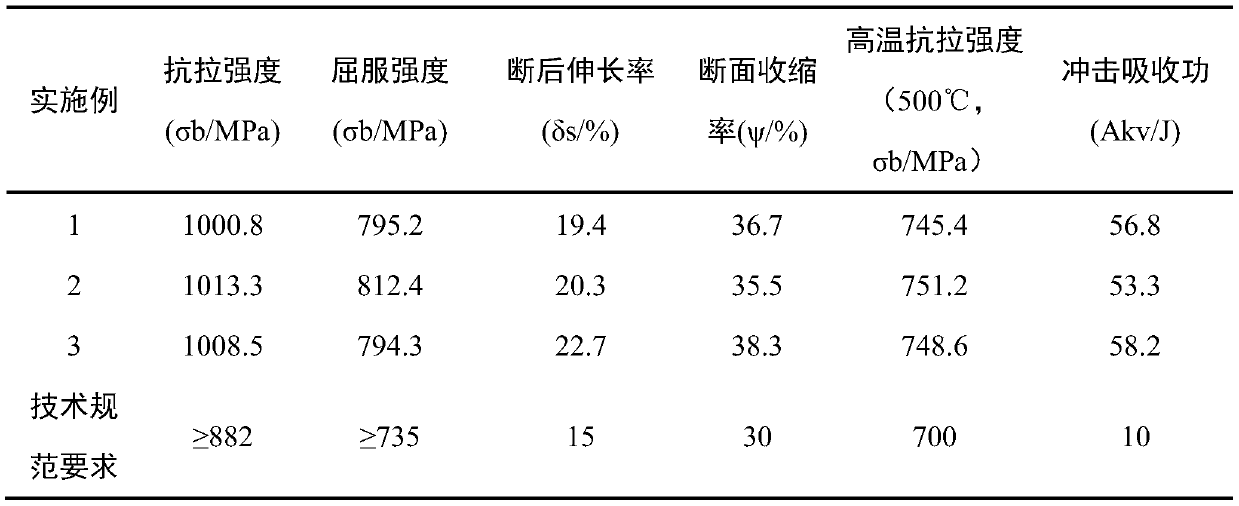

Examples

Embodiment 1

[0030] The alloy steel forged brake disc of the present embodiment and its processing steps are as follows:

[0031] Alloy steel forged brake disc with anti-friction spark characteristics, the components and their mass percentages are: C: 0.1, Cr: 1.0, Mo: 1.0, W: 0.5, Mn: 0.2, Ti: 0.1, Cu: 0.5, Nb: 0.05, V: 0.05, N: 0.005, RE: 0.001, P: ≤0.005, S: ≤0.02; the balance is Fe and unavoidable impurities.

[0032] A method for manufacturing an alloy steel forged brake disc with the characteristic of suppressing frictional sparks, comprising the following steps:

[0033] (1) Forging forming: ① The above-mentioned components are made into alloy steel, and the alloy steel is opened by free forging. The initial forging temperature of free forging is 1250 ° C, and the final forging temperature is 1100 ° C; For billet making, the deformation of the first rolling ring is 60%, the final forging temperature is 1158°C, and the interval is 100s, and the second ring rolling is carried out, th...

Embodiment 2

[0036] The alloy steel forged brake disc of the present embodiment and its processing steps are as follows:

[0037] Alloy steel forged brake disc with the characteristic of suppressing friction sparks, the components and their mass percentages are: C: 0.15, Cr: 1.5, Mo: 2.0, W: 1.0, Mn: 0.8, Ti: 0.5, Cu: 0.8, Nb: 0.1, V: 0.1, N: 0.015, RE: 0.008, P: ≤0.005, S: ≤0.02; the balance is Fe and unavoidable impurities.

[0038] A method for manufacturing an alloy steel forged brake disc with the characteristic of suppressing frictional sparks, comprising the following steps:

[0039] (1) Forging forming: ① The above-mentioned components are made into alloy steel, and the alloy steel is opened by free forging. The initial forging temperature is 1250 ° C, and the final temperature is 1100 ° C; The deformation of the rolling ring is 60%, the final forging temperature of the first rolling ring is 1160°C, and the interval is 50s, and the second ring rolling is carried out, the deformati...

Embodiment 3

[0042] The alloy steel forged brake disc of the present embodiment and its processing steps are as follows:

[0043] Alloy steel forged brake disc with the characteristic of suppressing friction sparks, the components and their mass percentages are: C: 0.12, Cr: 1.2, Mo: 1.5, W: 0.8, Mn: 0.5, Ti: 0.3, Cu: 0.7, Nb: 0.08, V: 0.07, N: 0.010, RE: 0.005, P: ≤0.005, S: ≤0.02; the balance is Fe and unavoidable impurities.

[0044] A method for manufacturing an alloy steel forged brake disc with the characteristic of suppressing frictional sparks, comprising the following steps:

[0045] (1) Forging molding: ① The above-mentioned components are made into alloy steel, and the alloy steel is opened by free forging. The initial forging temperature of free forging is 1250 °C, and the terminal temperature is 1100 °C; For the billet, the first ring rolling deformation is 70%, the final forging temperature is 1178°C, and the interval is 30s, and the second ring rolling is carried out, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com