A kind of copper-doped bismuth bimetallic material and its preparation and application

A bismuth metal and copper doping technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve poor stability, low current density, and low Faradaic efficiency and other issues, to achieve the effect of low cost, good conductivity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of CuBi electroplating solution under constant current density, described CuBi electroplating solution is used for electrodeposition Cu-doped-Bi metal electrode, and preparation method is:

[0043] Take 0.01mol trisodium citrate dihydrate, 0.01mol urea, 0.01mol ethylenediaminetetraacetic acid, 0.001mol Bi(NO 3 ) 3 ·5H 2 O and 0.001mol Cu(NO 3 ) 2 ·3H 2 O was successively dissolved in 100 mL deionized water. After stirring well, use 0.01M HNO 3 and 0.01M NaOH to adjust the pH to 6, add 0.68g sodium formate, stir well until clear and sonicate.

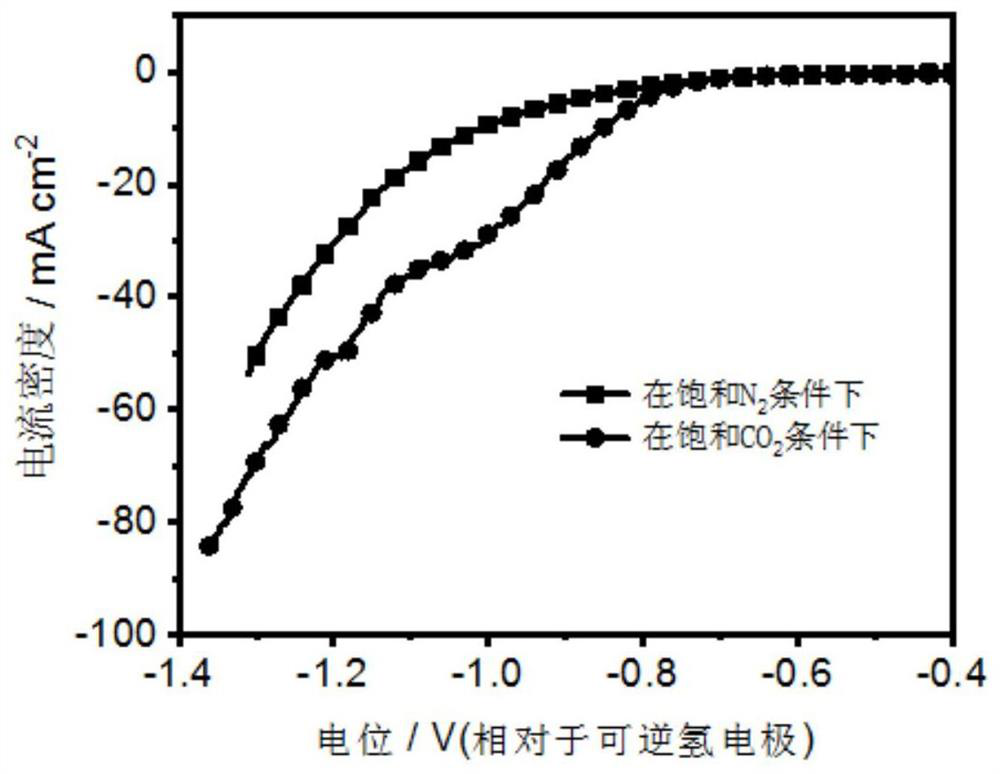

[0044] The pretreated foamed copper was cut into 1cm×1.5cm as the working electrode, and the spectroscopic graphite rod was used as the counter electrode, and the Cu-doped-Bi metal electrode for the electrochemical reduction of carbon dioxide was obtained by electrodeposition at 400mA for 1min. , called Cu (1) -doped-Bi (1) -400.

Embodiment 2

[0046] The preparation method of CuBi electroplating solution under constant current density, described CuBi electroplating solution is used for electrodeposition Cu-doped-Bi metal electrode, and its preparation method is:

[0047] Take 0.01mol trisodium citrate dihydrate, 0.01mol urea, 0.01mol ethylenediaminetetraacetic acid, 0.001mol Bi(NO 3 ) 3 ·5H 2 O and 0.00025mol Cu(NO 3 ) 2 ·3H 2 O was successively dissolved in 100 mL deionized water. After stirring well, use 0.01M HNO 3 and 0.01M NaOH to adjust the pH to 6, add 0.68g sodium formate, stir well until clear and sonicate.

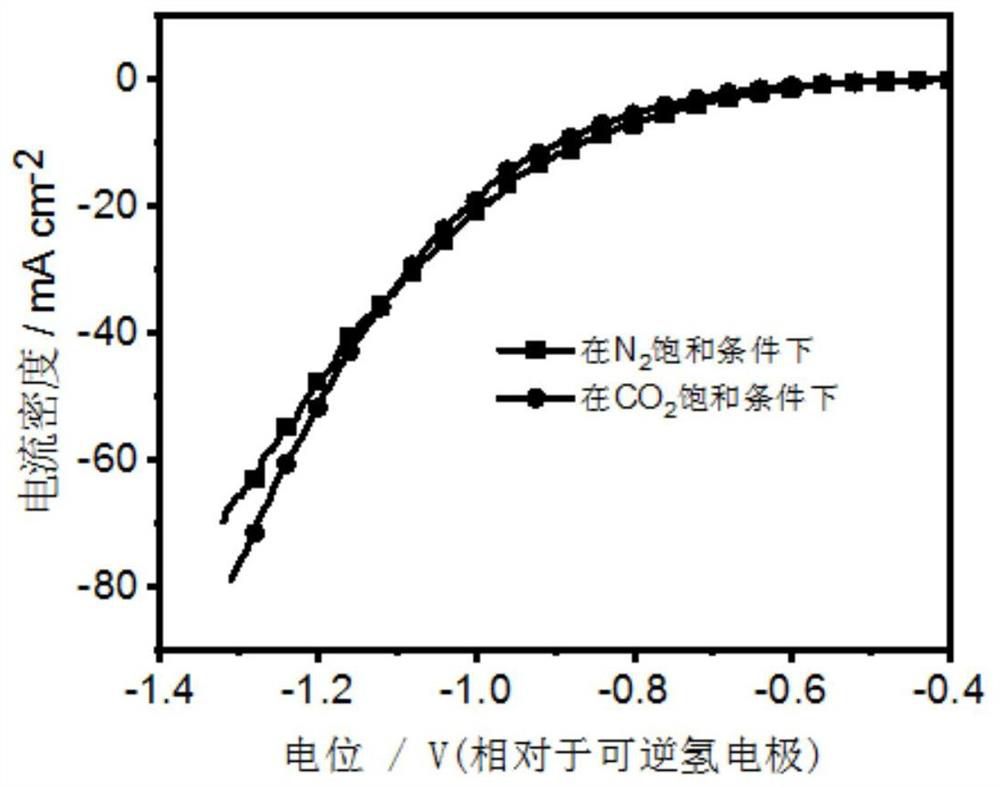

[0048] The pretreated foamed copper was cut into 1cm×1.5cm as the working electrode, and the spectroscopic graphite rod was used as the counter electrode, and the Cu-doped-Bi metal electrode for the electrochemical reduction of carbon dioxide was obtained by electrodeposition at 400mA for 1min. , called Cu (0.25)- doped-Bi (1) -400.

Embodiment 3

[0050] Preparation method of CuBi electroplating solution under constant current density. Described CuBi electroplating solution is used for electrodeposition Cu-doped-Bi metal electrode, and its preparation method is:

[0051] Take 0.01mol trisodium citrate dihydrate, 0.01mol urea, 0.01mol ethylenediaminetetraacetic acid, 0.001mol Bi(NO 3 ) 3 ·5H 2 O and 0.00025mol Cu(NO 3 ) 2 ·3H 2 O was successively dissolved in 100 mL deionized water. After stirring well, use 0.01M HNO 3 and 0.01M NaOH to adjust the pH to 6, add 0.68g sodium formate, stir well until clear and sonicate.

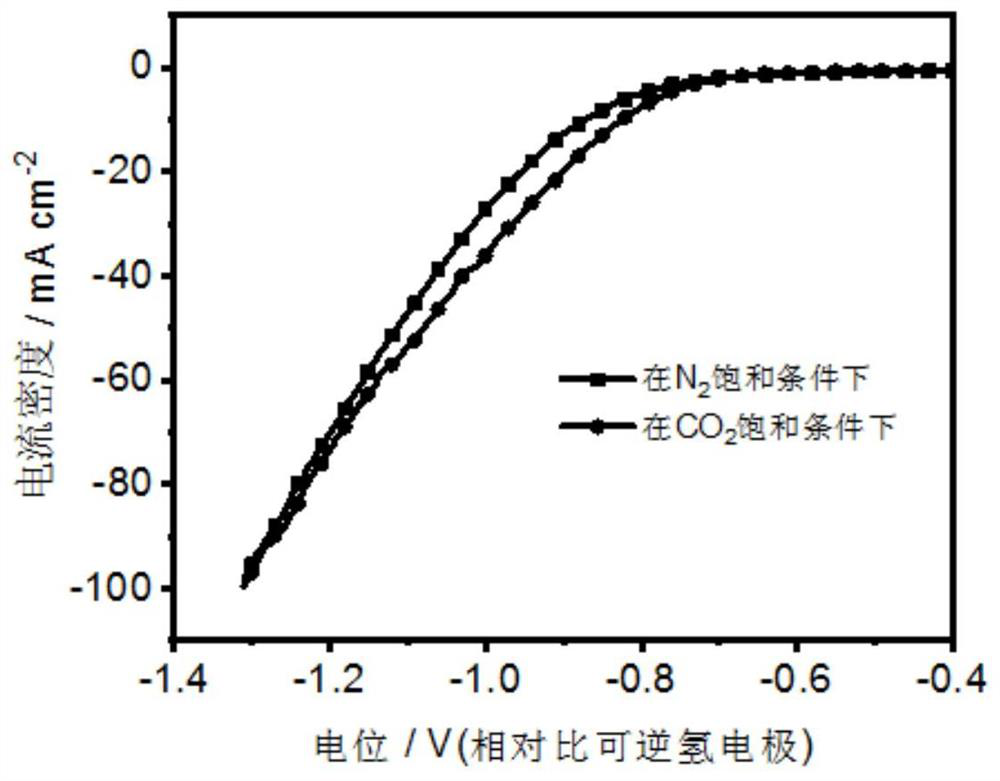

[0052] The pretreated foamed copper was cut into 1cm×1.5cm as the working electrode, and the spectroscopic graphite rod was used as the counter electrode, and the Cu-doped-Bi metal electrode for the electrochemical reduction of carbon dioxide was obtained under the condition of 100mA for 1min. , called Cu (0.25)- doped-Bi (1) -100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com