Filtering-based intelligent fault detection method for motors in industrial field

A fault detection and intelligent technology, applied in the direction of motor generator testing, measuring electricity, measuring devices, etc., can solve the problems of large amount of calculation, poor real-time performance, and difficult to describe statistical characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

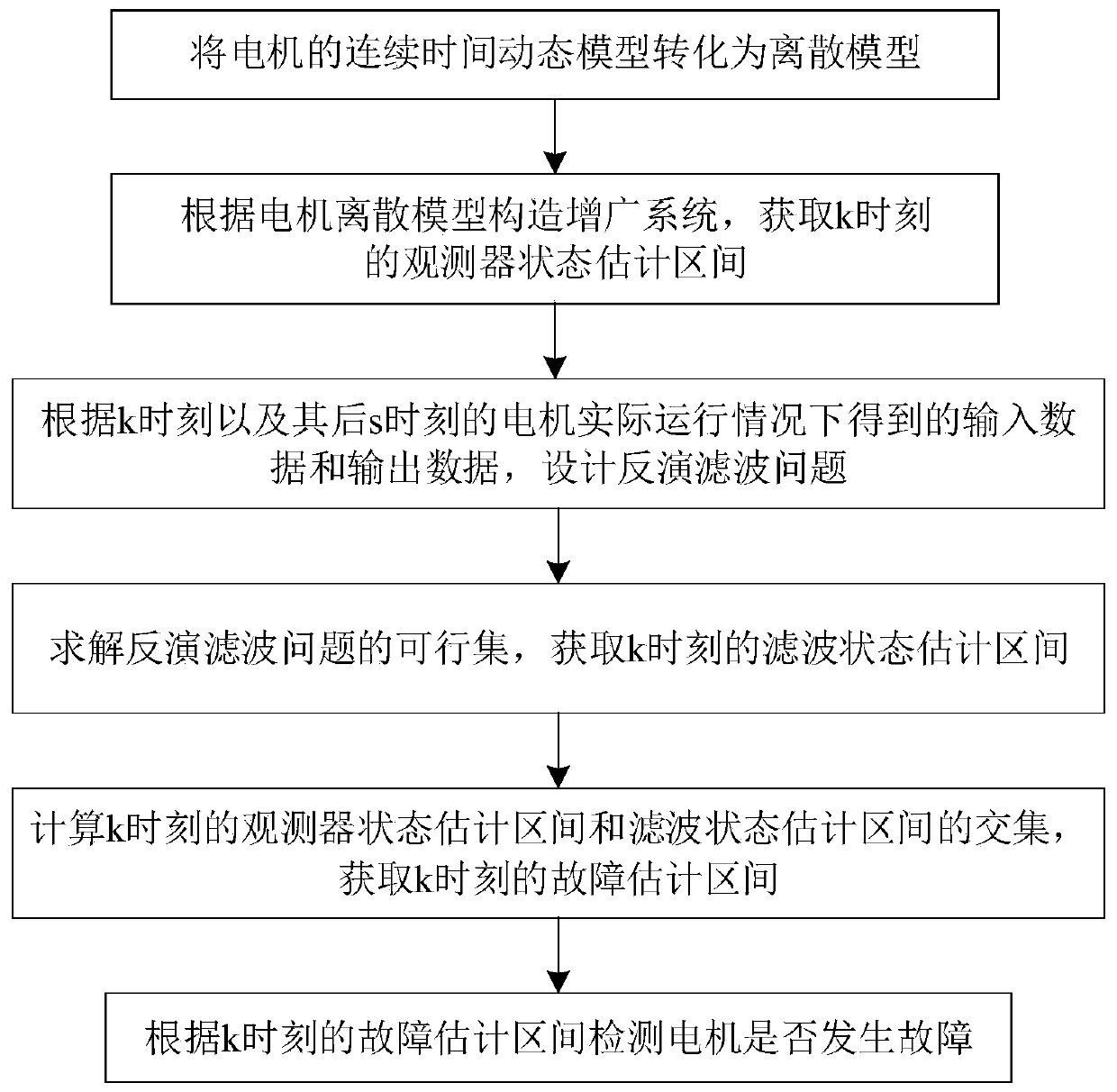

[0076] This embodiment provides a filter-based intelligent motor fault detection method in the industrial field, see figure 1 , the method includes:

[0077] Step 1: Establish a discrete model of the permanent magnet DC motor.

[0078] According to the working principle of the permanent magnet DC motor, the continuous time nonlinear dynamic model is obtained:

[0079]

[0080] Among them, u represents the armature voltage, K e Represents the counter electromotive force coefficient, n represents the motor speed, R a Represents resistance, i represents current, L 1 Indicates the inductance, K t Indicates the torque coefficient, T 0 and T 2 Represents the no-load torque and load torque respectively, J represents the moment of inertia of the rotor and the load, and Ω represents the angular velocity.

[0081] The no-load torque T produced by the losses of the motor 0 Equivalent to the friction in the bearings or the friction between the brushes and the commutator to prod...

Embodiment 2

[0138] This embodiment provides a filter-based intelligent motor fault detection system in the industrial field, using the intelligent fault detection method described in Embodiment 1 to detect faults on motors, specifically:

[0139] Use the MAX472 current sense amplifier to measure the armature current i when the permanent magnet DC motor is running, and the photoelectric encoder to measure the motor speed n.

[0140] Apply a DC voltage u to the motor, and measure the no-load speed n 0 , no-load current I 0 , no-load time constant T a and load speed n 2 , load current I 2 , the time t required for the armature current to reach 0.95 times the current of the motor in stable operation s , the parameters of the motor are obtained as follows:

[0141] Armature resistance R a for:

[0142]

[0143] Inductance L 1 for:

[0144]

[0145] Coefficient of counter electromotive force K e for:

[0146]

[0147] The viscous friction coefficient f of the motor bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com