Laser wire feeding welding method for aluminum-silicon-coated hot formed steel

A welding method and technology for hot forming steel, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of lack of non-destructive testing methods for joints, reduce joint quality, etc., to solve surface collapse, improve mechanical properties, simplify The effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The laser wire-feed welding method of the aluminum-silicon-coated thermoformed steel of this embodiment includes:

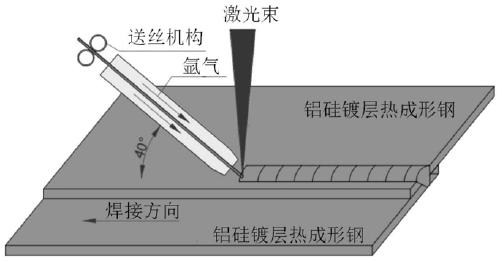

[0029] The aluminum-silicon-coated hot-formed steel pre-treated according to the figure 1 Assembled as shown to form a lap joint, the length of the lap is 5 mm, and the gap between the laps is 0.1 mm. Under the condition of filling welding wire, the aluminum-silicon-coated thermoforming steel is lapped by laser wire feeding process. The welding wire is ER110S-G high-strength steel welding wire with a diameter of 1.2mm. is 40°. The incident angle of the laser is 85°.

[0030] In the laser wire feeding process, the welding process parameters are: the laser power is 2kW, the welding speed is 1m / min, and the wire feeding speed is 0.7m / min. When argon is used for protection, the flow rate of argon is 15L / min.

[0031] After welding, it was observed that the entire weld was in good shape, without spatter, and it was a fully-penetrated weld. The center of th...

Embodiment 2

[0033] The laser wire-feed welding method of the aluminum-silicon-coated thermoformed steel of this embodiment includes:

[0034] The aluminum-silicon-coated hot-formed steel pre-treated according to the figure 1 Assembled as shown to form a lap joint, the length of the lap is 5 mm, and the gap between the laps is 0.1 mm. Under the condition of filling welding wire, the aluminum-silicon-coated thermoforming steel is lapped by laser wire feeding process. The welding wire is ER110S-G high-strength steel welding wire with a diameter of 1.2mm. is 40°. The incident angle of the laser is 85°.

[0035] In the laser wire feeding process, the welding process parameters are: the laser power is 2.5kW, the welding speed is 1.5m / min, and the wire feeding speed is 1.2m / min. When argon is used for protection, the flow rate of argon is 15L / min.

[0036]After welding, it was observed that the entire weld was in good shape, without spatter, and it was a fully-penetrated weld. The center of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com