Polyamide 5X resin capable of rapidly crystallizing and preparation method thereof

A technology of polyamide resin and polyamide, which is applied in the field of rapid crystallization and molding of polyamide 5X and its preparation, can solve the problems of time-consuming and labor-intensive, and achieve the effects of suppressing the greenhouse effect, increasing production, and improving surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

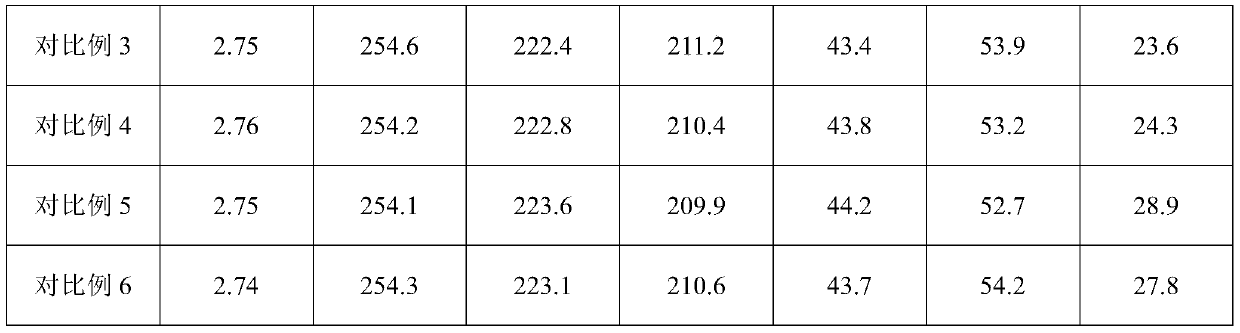

Embodiment 1

[0063] (1) Under nitrogen, mix 1,5-pentanediamine, adipic acid and water evenly to obtain a 70% polyamide salt solution, wherein the salt weighs 20kg; 1,5-pentanediamine and adipic acid The molar ratio is (1-1.05):1, and the pH value of the polyamide salt solution is 7.96 when the concentration of the polyamide salt solution is 10wt.%. The percentage is the mass percentage of the polyamide salt solution.

[0064] (2) Heat the salt solution of polyamide, the pressure in the reaction system rises to 1.7Mpa, exhaust, keep the pressure, the temperature of the reaction system at the end of the pressure keeping is 245°C, and then reduce the pressure to reduce the pressure in the reaction system to 0.01MPa (gauge pressure), the temperature of the reaction system was 262° C. after the end of depressurization.

[0065] (3) 1.6g nucleating agent P200 (Bruggmann, analytically pure) is configured into 5wt.% aqueous suspension and is added in the reactor through the feeding port, and the a...

Embodiment 2

[0070] (1) Under nitrogen, mix 1,5-pentanediamine, adipic acid and water evenly to obtain a 72% polyamide salt solution, wherein the salt weighs 20kg; 1,5-pentanediamine and adipic acid The molar ratio is (1-1.05):1, and the pH value of the polyamide salt solution is 7.98 when the concentration of the polyamide salt solution is 10wt.%. The percentage is the mass percentage of the polyamide salt solution.

[0071] (2) Heat the salt solution of polyamide, the pressure in the reaction system rises to 1.7Mpa, exhaust, keep the pressure, the temperature of the reaction system at the end of the pressure keeping is 248°C, and then reduce the pressure to reduce the pressure in the reaction system to 0.01MPa (gauge pressure), the temperature of the reaction system was 264° C. after the end of depressurization.

[0072] (3) 1.6g nucleating agent P200 (Bruggmann, analytically pure) is configured into 5wt.% aqueous suspension and is added in the reactor through the feeding port, and the a...

Embodiment 3

[0076] (1) Under nitrogen, mix 1,5-pentanediamine, adipic acid and water evenly to obtain a 70% polyamide salt solution, wherein the salt weighs 20kg; 1,5-pentanediamine and adipic acid The molar ratio is (1-1.05):1, and the pH value of the polyamide salt solution is 7.96 when the concentration of the polyamide salt solution is 10wt.%. The percentage is the mass percentage of the polyamide salt solution.

[0077] (2) Heat the salt solution of polyamide, the pressure in the reaction system rises to 1.7Mpa, exhaust, keep the pressure, the temperature of the reaction system at the end of the pressure keeping is 245°C, and then reduce the pressure to reduce the pressure in the reaction system to 0.01MPa (gauge pressure), the temperature of the reaction system was 262° C. after the end of depressurization.

[0078] (3) 1.0g of nucleating agent P200 (Bruggmann, analytically pure) is configured into 5wt.% water suspension and added in the reactor through the feeding port, and the add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com