Engineering rock mass mechanical parameter advance borehole in-situ test device and application method thereof

A technology of rock mechanics and advanced drilling, applied in earthwork drilling, wellbore/well components, construction, etc., can solve the problem of difficulty in ensuring the drilling depth, achieve wide practicability and application value, facilitate access, reduce The effect of financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

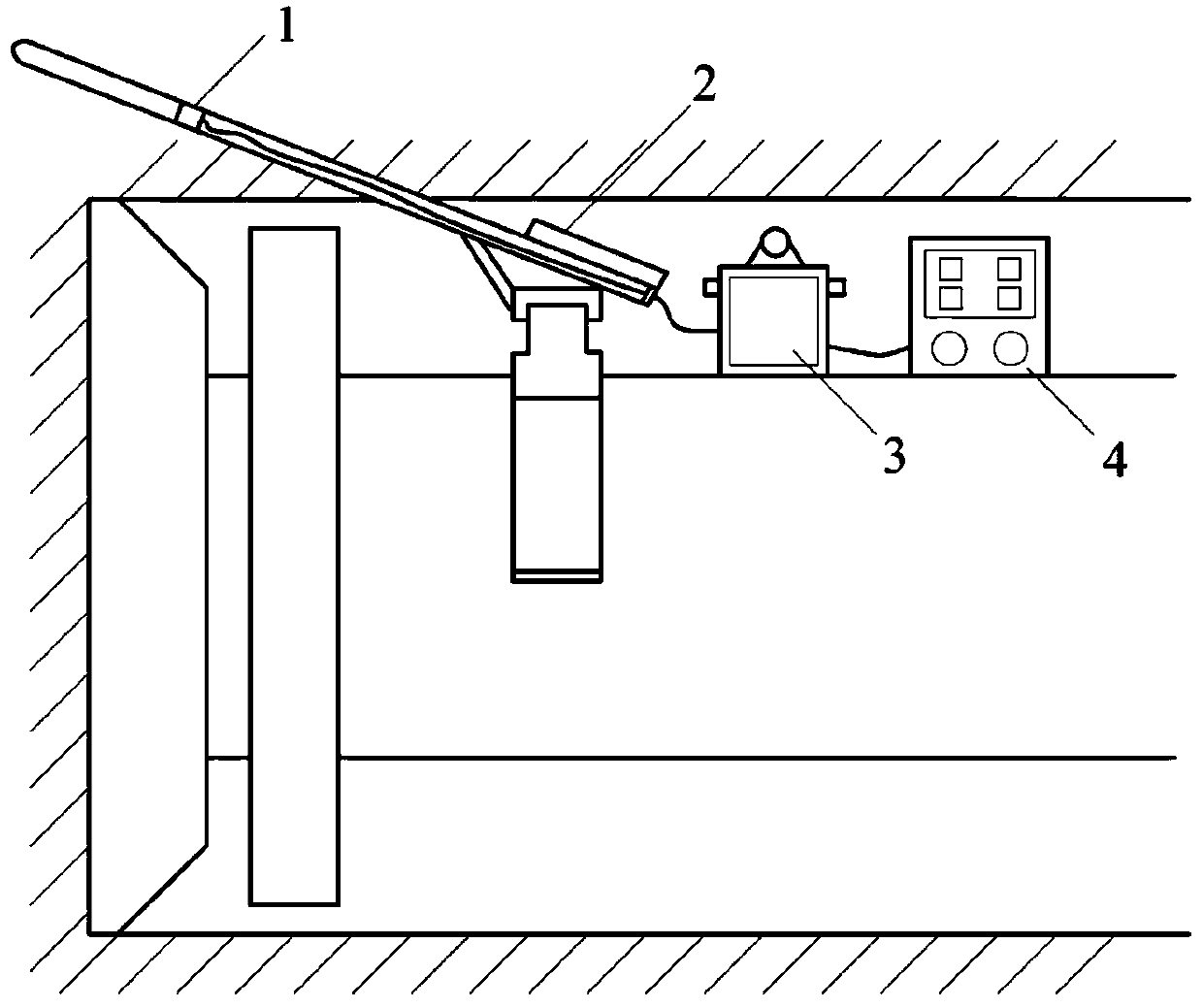

[0056] Such as figure 1 As shown, the advanced drilling in-situ test device for mechanical parameters of engineering rock mass of the present invention includes four parts: a penetrating loading system 1 , a TBM advanced drill pipe 2 , a hydraulic loading system 3 and a control system 4 .

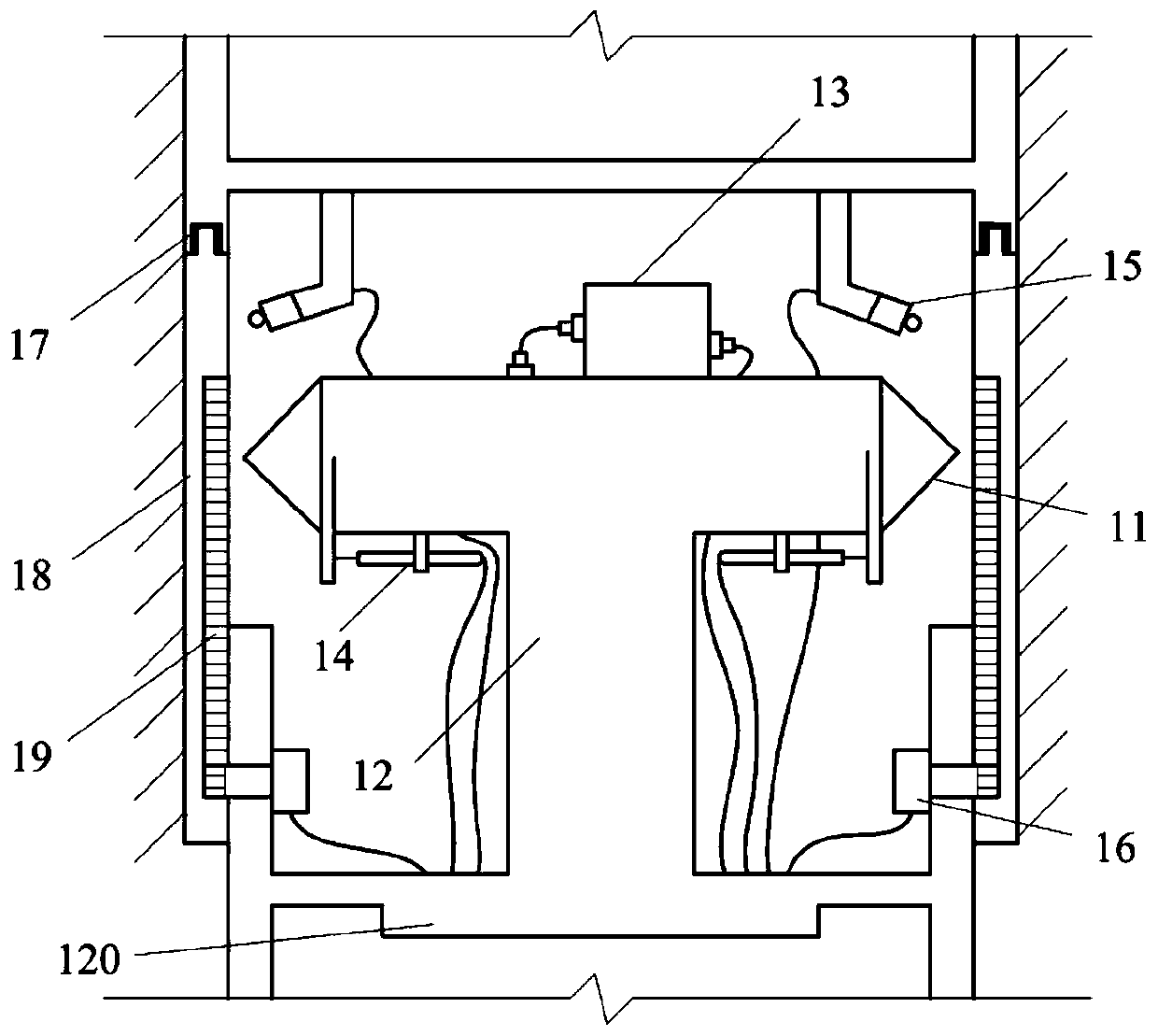

[0057] 1. Touch loading system ( figure 2 , Figure 4 )

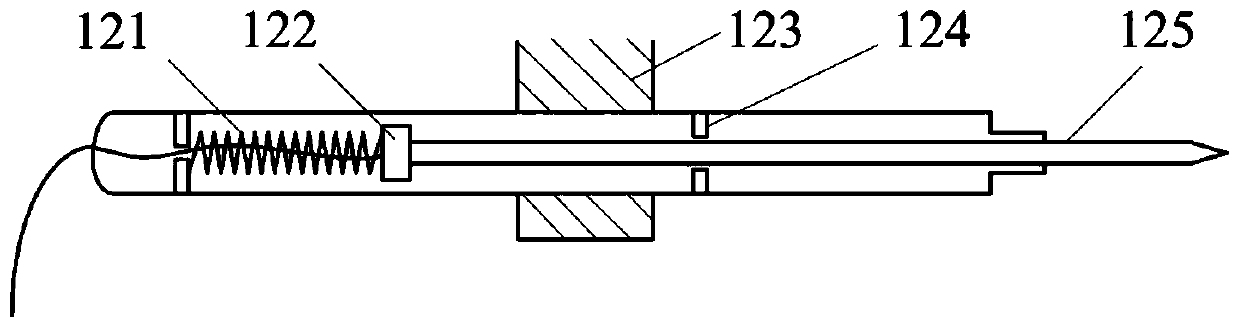

[0058] The touch loading system includes a base plate 120, a top plate 136, a cone probe 11, a support frame 137, a propulsion frame 129, an oil cylinder 12, a pressure sensor 13, a displacement sensor 14 and a video camera 15; the video camera 15 is arranged below the top plate 136, Used to photograph the surface information of the borehole wall;

[0059] The bottom plate 120 and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com