Industrial salt drying system and method

A drying system and industrial salt technology, applied in separation methods, dry solid materials, dry cargo handling, etc., can solve problems such as irrational dust removal effect, unfavorable production efficiency, and easily damaged equipment, so as to reduce the risk of material agglomeration, Facilitate cooling effect and reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

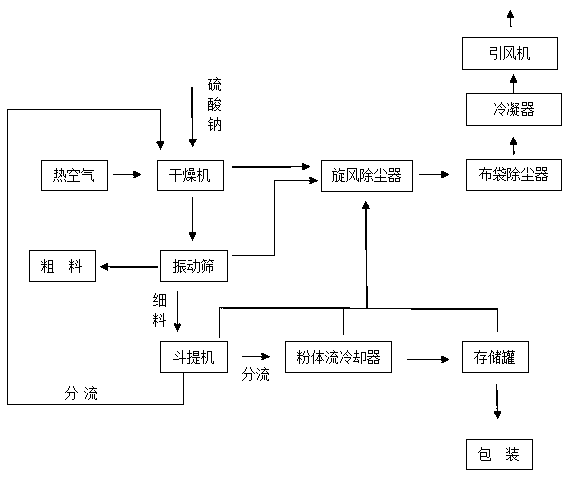

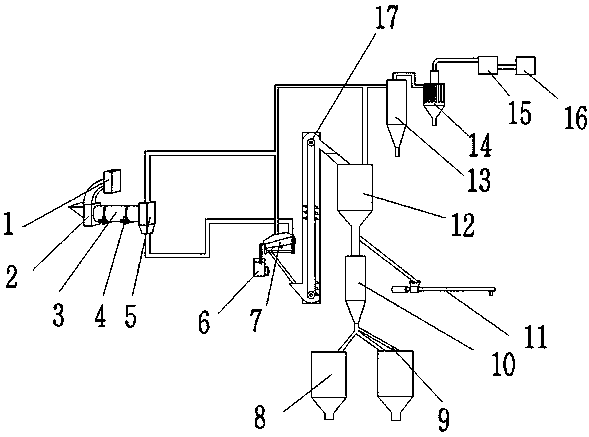

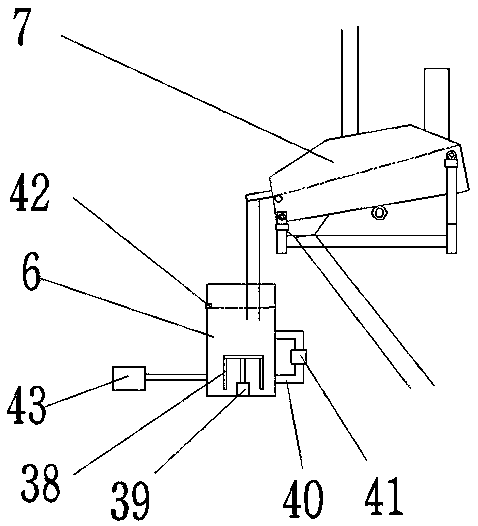

[0040]As shown in the accompanying drawings: a sodium sulfate drying system, including a drying system, a screening and separation system and a dust removal system, the drying system includes a dryer 3, the screening and separation system includes a vibrating screen 7, and the discharge end of the dryer 3 is connected to a vibrating The sieve 7 and the vibrating screen 7 are provided with a dust removal port, which is connected to the dust removal system. The vibrating screen 7 is also provided with a fine material outlet and a coarse material outlet. The solvent in the body and the staving, the pipeline is always below the solvent level, and the staving is provided with a return pipe 40.

[0041] Preferably, a circulating pump 41 is provided on the return pipe 40 to facilitate the flow of the solution in the barrel and improve the dissolution efficiency of the material in the barrel. The dissolved solution is discharged through the delivery pump 43 to avoid excessive overflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com