Lithium-ion power battery recycling method

A power battery and recycling method technology, which is applied in the field of solid waste and electronic waste recycling, can solve the problems of high energy consumption, large environmental impact, and low efficiency, and achieve the effect of less environmental impact, small usage, and guaranteed efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

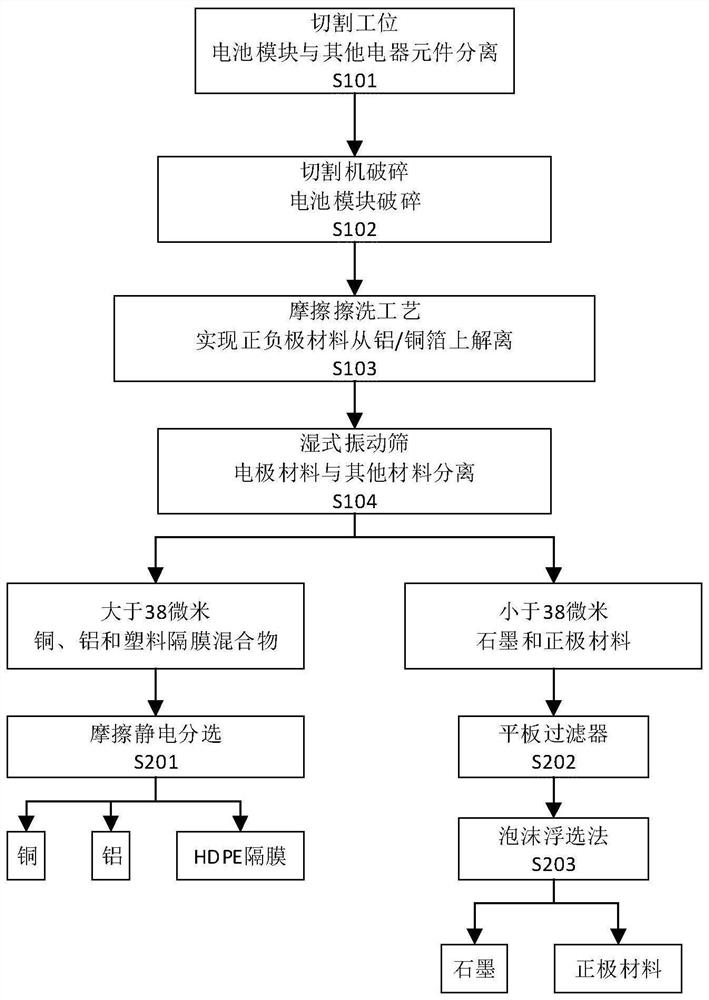

[0067] S101, remove the electronic components on the waste battery;

[0068] S102, crushing 200 grams of disassembled waste batteries with a cutting crusher, and using an 8 mm bottom sieve for bottom screening;

[0069] S103. The friction scrubbing process is controlled at 60% according to the pulp density, and the mass ratio of the battery material to the friction medium is 20%. Mix 200 grams of broken waste batteries, 800 grams of friction medium quartz sand and 667 grams of water, and put them into the friction scrubbing machine. Scrub time is 10 minutes. The above ratio of friction scrubbing can significantly increase the dissociation rate of the electrode active material from the electrode metal foil, while maintaining the unfolded state of the electrode metal foil, ensuring the efficiency of subsequent triboelectric separation.

[0070] S104. Put the dissociated mixed material on the electrode sheet into a wet vibrating sieve, set the working time of the vibrating siev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com