Motor drive control system with learning function

A technology of motor drive control and learning function, applied in control systems, motor control, electric components, etc., can solve the problems of difficult heat conduction efficiency between heat dissipation medium and fins, affecting the normal operation of motor rotors, etc., to increase cleaning effect and improve heat dissipation. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

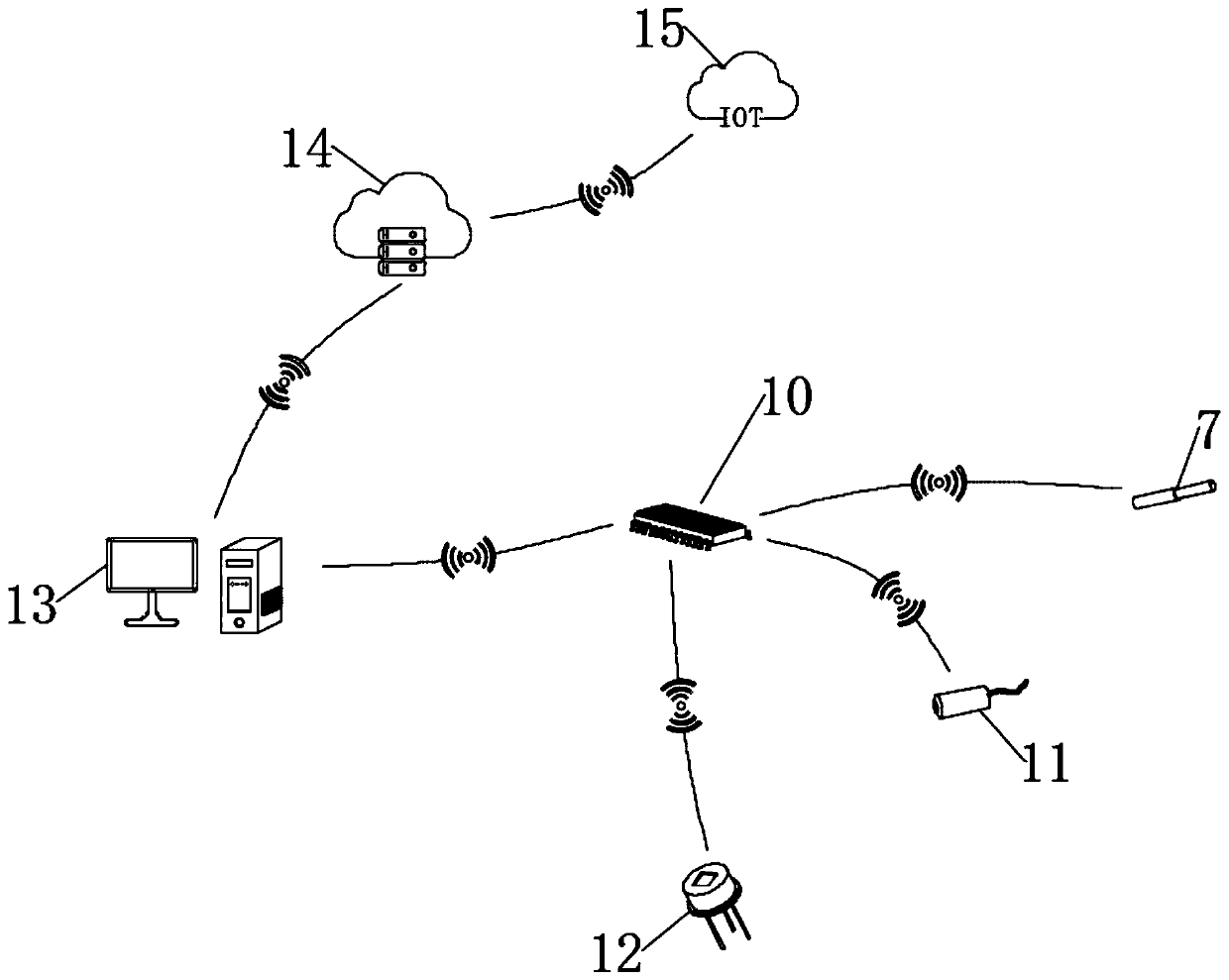

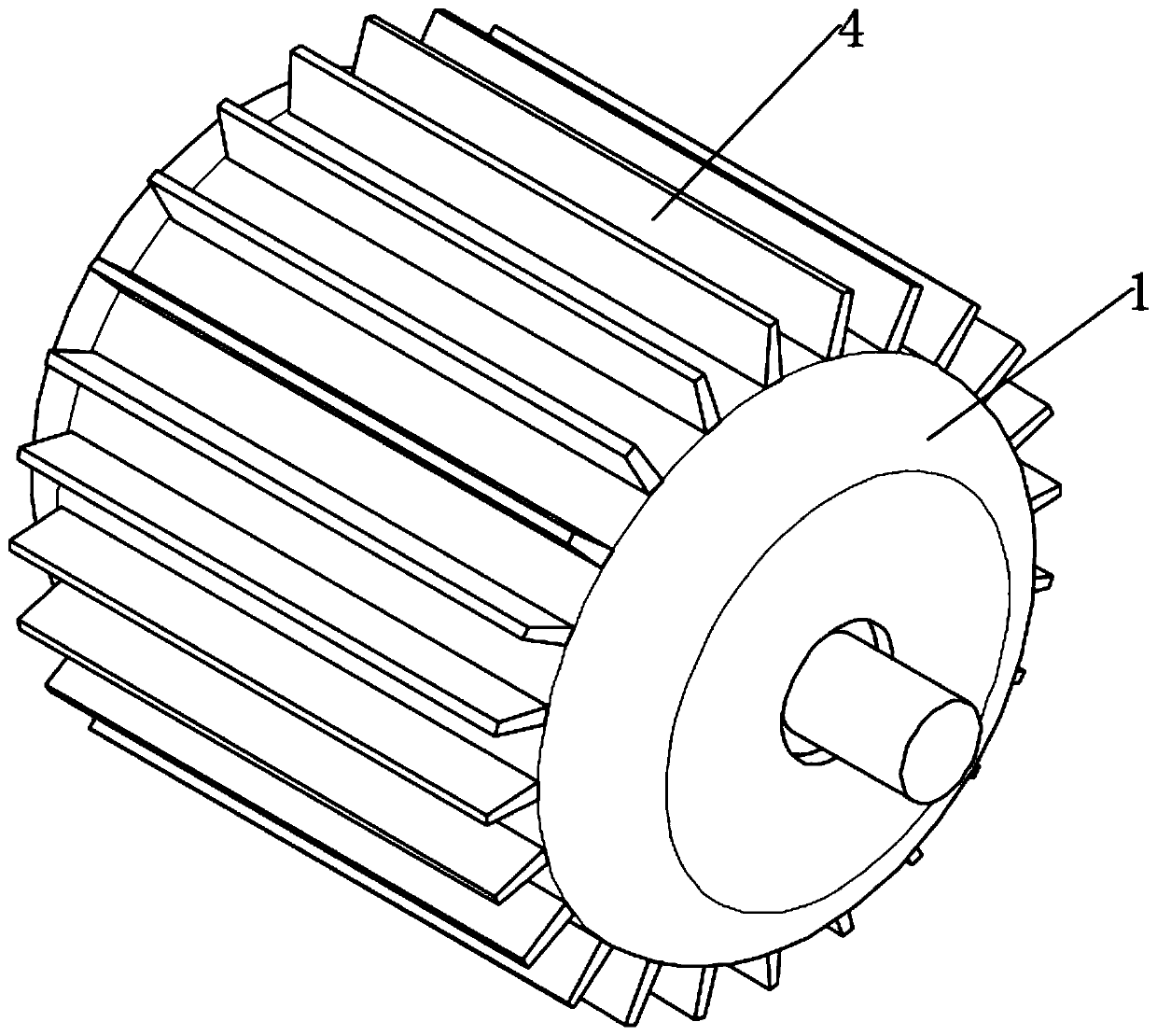

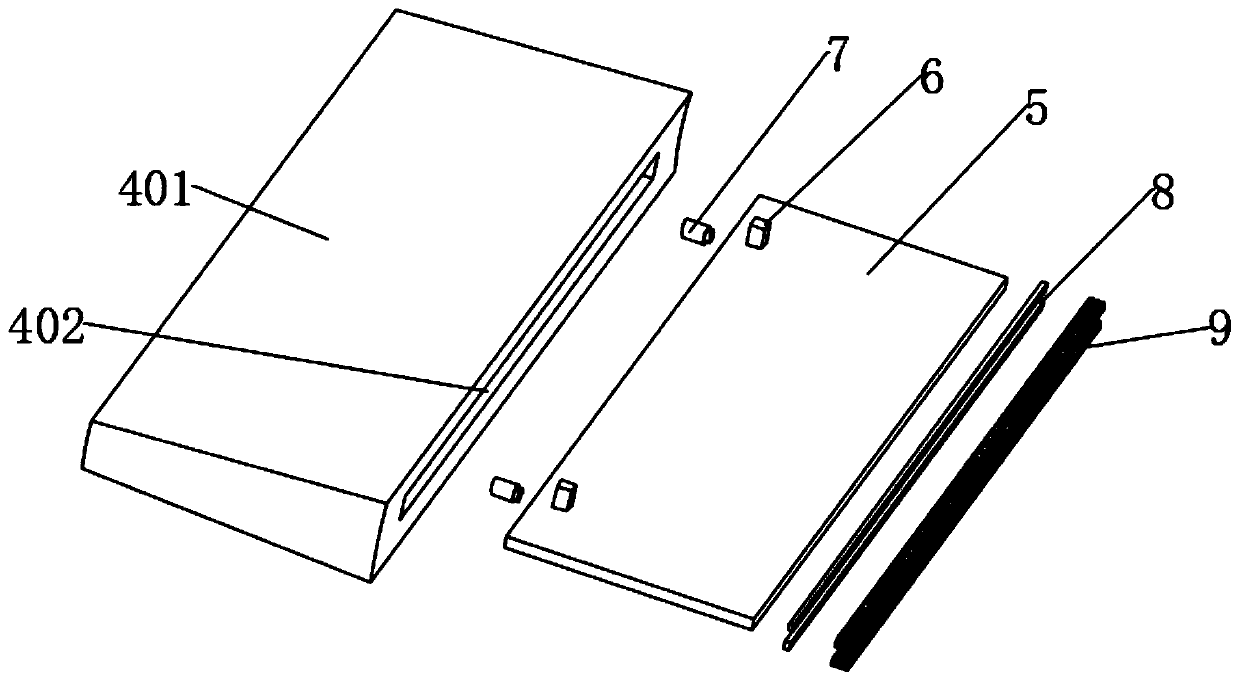

[0039] see Figure 2-5 , a motor drive control system with a learning function, comprising a motor main body 1 and a processing terminal 10, the processing terminal 10 controls the normal operation of the motor main body 1, the motor main body 1 includes a motor casing 2 and a motor inner chamber 3, and the motor inner chamber 3 The outer side is fixedly connected with a heat dissipation fin 4, the heat dissipation fin 4 includes a fin body 401, a section of the fin body 401 close to the motor casing 2 runs through the motor casing 2, and a movable cavity 402 is dug in the fin body 401, and the movable cavity 402 is connected to the motor casing 2. The motor inner cavity 3 is connected, the movable cavity 402 is plugged with compensation fins 5, and the side wall of the movable cavity 402 is dug with a plurality of limit chute 403, and the side wall of the compensation fin 5 is fixedly connected with a plurality of The limit chute 403 matched with the side wing slider 6, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com