Process for processing leisure bean-curd stick food and processing line used by same

A processing technology and processing line technology, applied in the field of soybean product production technology and equipment, to achieve the effects of adding flavor and taste, reducing labor configuration, convenient and efficient rehydration and cutting processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

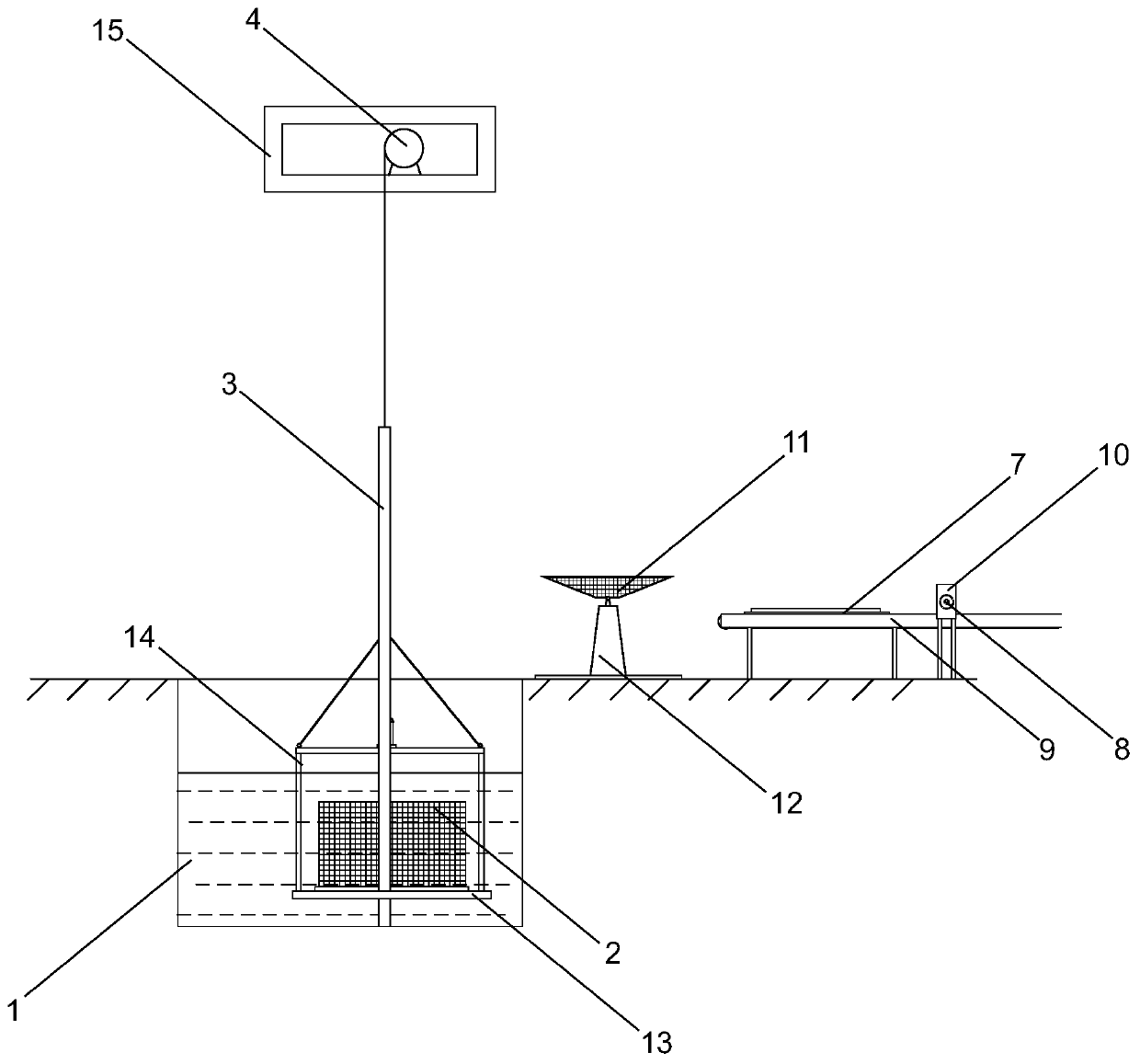

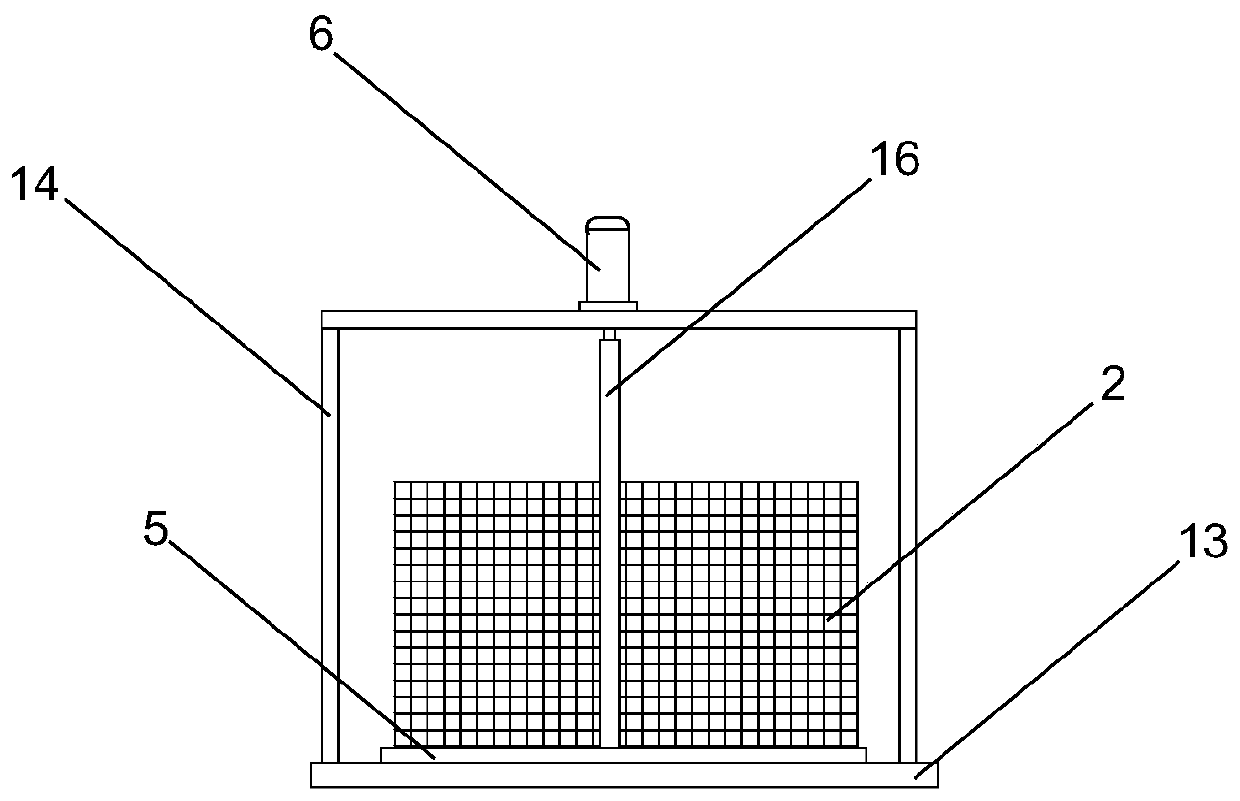

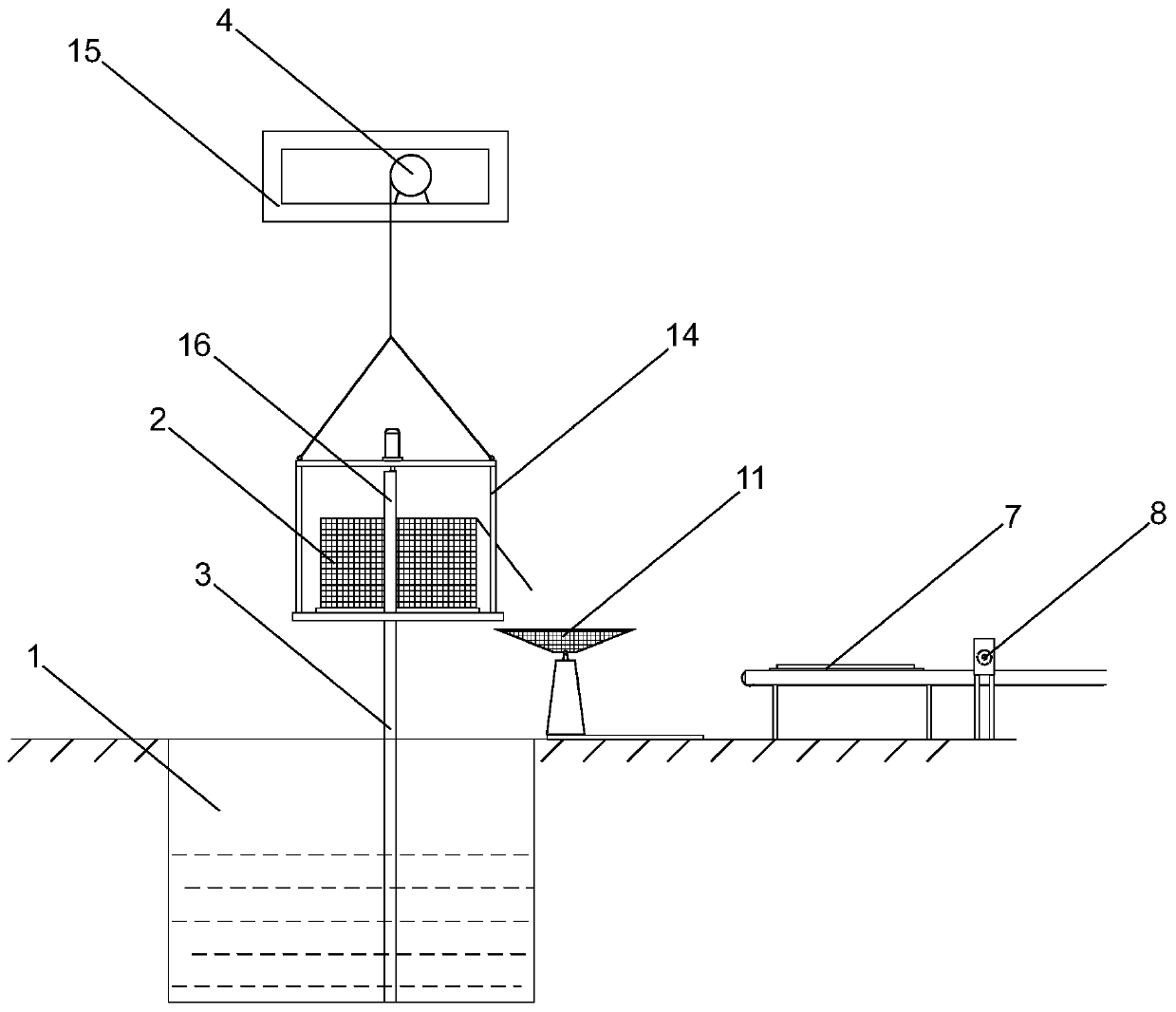

Image

Examples

Embodiment 1

[0036] A kind of processing technology of leisure bean curd stick food is characterized in that comprising the steps:

[0037] Step 1. Selection of materials: choose bean curd sticks with light yellow color, bright color, thin strip shape, hollow inside, fine texture, no peculiar smell, no mildew, and no foreign impurities visible to the naked eye;

[0038] Step 2. Rehydration: Soak the bean curd sticks on the rehydration and cutting processing line until the rehydration is complete and there are no lumps, and soak the bean curd sticks in clean water for 8 hours according to the ratio of material to water 1:3;

[0039] Step 3. Cut into sections: Arrange the rehydrated bean curd sticks into piles, cut them into sections on the rehydration and section processing line, and cut them into small sections of 4.8 cm;

[0040] Step 4. Dehydration: Rinse the cut bean curd sticks twice with clean water, and then put them into the centrifuge for dehydration until no water can be squeezed ...

Embodiment 2

[0052] Step 2 Soak the bean curd sticks in clean water for 7 hours according to the ratio of material to water 1:4; step 6, add 900 parts of water, 450 parts of bean curd sticks, 18 parts of salt, 8 parts of monosodium glutamate, 8 parts of white sugar, yeast 2 parts of extract, 1 part of star anise, 2 parts of cinnamon bark and 1 part of bay leaves, marinated for 28 minutes; step 8, the temperature is 52 ℃, and the baking time is 18 minutes. The ingredients used in step 9 are: 100 parts of dried semi-finished product, 8 parts of vegetable oil, 4 parts of white sesame, 0.6 part of chili powder, 4 parts of chili red oil, 0.2 part of edible essence, and stir evenly. The bean curd stick after the rehydration in the step 3 is cut into the segment of 4.5cm, and the distance between the corresponding circular blades is 4.5cm. All the other are with embodiment 1.

Embodiment 3

[0054] Step 2 Soak the bean curd sticks in clean water for 5 hours according to the ratio of material to water 1:5; Step 6: Add 1000 parts of water, 500 parts of bean curd sticks, 20 parts of salt, 10 parts of monosodium glutamate, 10 parts of white sugar, yeast 3 parts of extract, 2 parts of star anise, 2 parts of cinnamon bark and 1 part of bay leaves, marinate for 30 minutes; Step 8 temperature is 55 ℃, baking time is 15 minutes. The ingredients used in step 9 are: 100 parts of dried semi-finished product, 10 parts of vegetable oil, 5 parts of white sesame, 0.8 part of chili powder, 5 parts of red pepper oil, 0.3 part of edible essence, and stir evenly. The bean curd stick after rehydration in step 3 is cut into 5.0cm segments, and the distance between the corresponding circular blades is 5.0cm. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com