Monascus vinegar fermentation beverage and preparation method thereof

A technology of fermented beverages and red yeast vinegar, which is applied in the field of condiments, can solve the problems of ineffective lowering of human cholesterol, blood sugar and blood pressure, and low content of functional ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

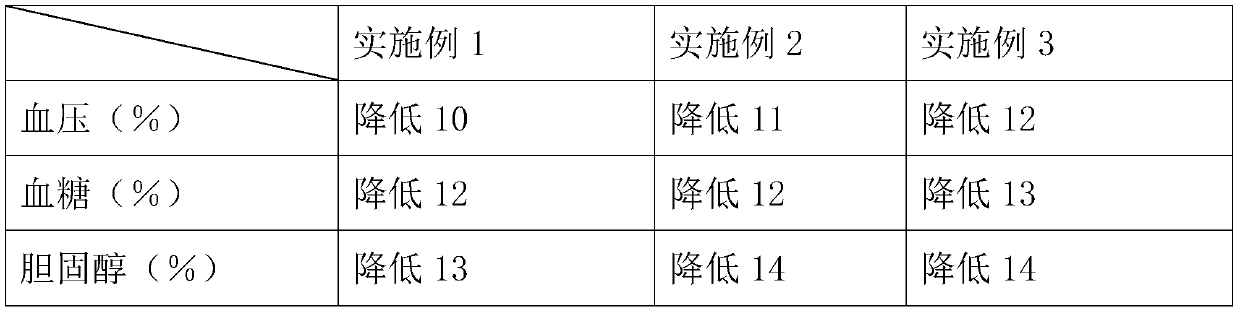

Examples

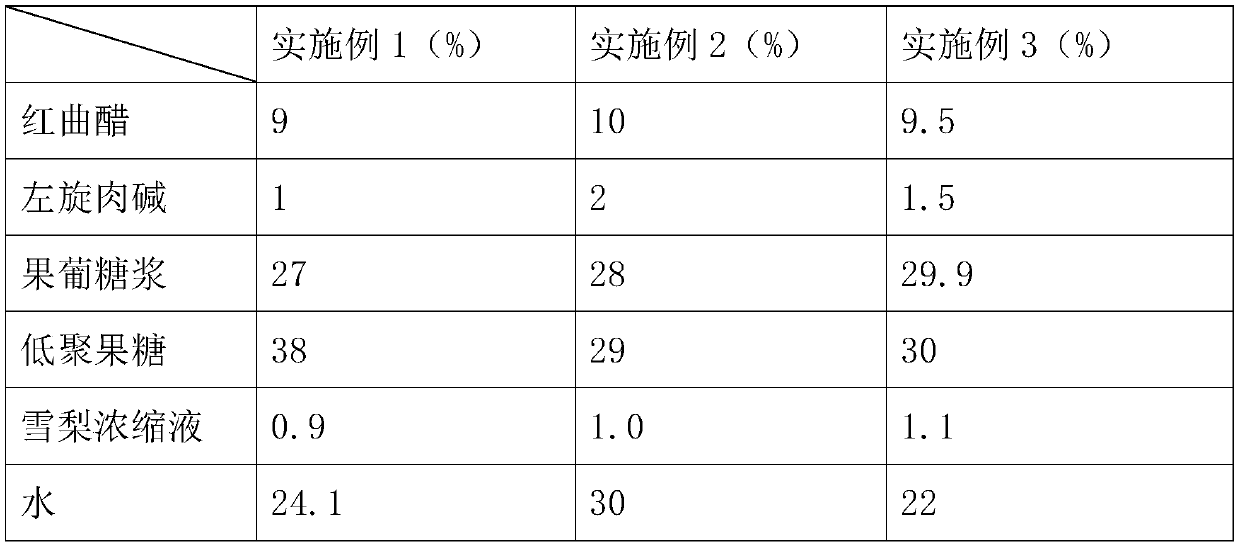

Embodiment 1

[0023] S1. Weigh the raw materials for later use. Weigh red yeast vinegar 9, L-carnitine 1, fructose syrup 27, fructo-oligosaccharide 38, Sydney concentrate 0.9, and water 24.1 for later use according to the preparation requirements. During the weighing process, use a special Measuring tools cannot be mixed to ensure the accuracy of raw material components. The fructose syrup is fructose syrup type 55;

[0024] S2. Mix the red yeast rice vinegar and fructo-oligosaccharides. When mixing the red yeast rice vinegar and fructo-oligosaccharides, add them gradually. Use a stirring tank to stir to ensure the uniformity of mixing. Saccharify the red yeast rice to obtain 12% sugar content The saccharified mash is added with yeast for fermentation, the temperature during fermentation is controlled at 220-230 ° C, and the fermentation time is 4-8 days;

[0025] S3. After the alcohol fermentation is completed, test the alcohol level. When the alcohol level is 5-9%, carry out acetic acid f...

Embodiment 2

[0028] S1. Weigh the raw materials for later use. Weigh red yeast vinegar 10, L-carnitine 2, fructose syrup 28, fructo-oligosaccharide 29, Sydney concentrate 1.0, and water 30 for later use according to the preparation requirements. During the weighing process, use a special Measuring tools cannot be mixed to ensure the accuracy of raw material components. The fructose syrup is fructose syrup type 55;

[0029] S2. Mix the red yeast rice vinegar and fructo-oligosaccharides. When mixing the red yeast rice vinegar and fructo-oligosaccharides, add them gradually. Use a stirring tank to stir to ensure the uniformity of mixing. Saccharify the red yeast rice to obtain 12% sugar content The saccharified mash is added with yeast for fermentation, the temperature during fermentation is controlled at 220-230 ° C, and the fermentation time is 4-8 days;

[0030] S3. After the alcohol fermentation is completed, test the alcohol level. When the alcohol level is 5-9%, carry out acetic acid fe...

Embodiment 3

[0033] S1. Weigh the raw materials for later use. According to the preparation requirements, weigh 9.5% of red yeast rice vinegar, 1.5% of L-carnitine, 29.9% of fructose syrup, 30% of fructo-oligosaccharide, 1.1% of Sydney concentrate, and 22% of water for later use. Measuring tools are not allowed to be mixed to ensure the accuracy of raw material components. The fructose syrup is fructose syrup type 55;

[0034] S2. Mix the red yeast rice vinegar and fructo-oligosaccharides. When mixing the red yeast rice vinegar and fructo-oligosaccharides, add them gradually. Use a stirring tank to stir to ensure the uniformity of mixing. Saccharify the red yeast rice to obtain 12% sugar content The saccharified mash is added with yeast for fermentation, the temperature during fermentation is controlled at 220-230 ° C, and the fermentation time is 4-8 days;

[0035] S3. After the alcohol fermentation is completed, test the alcohol level. When the alcohol level is 5-9%, carry out acetic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com