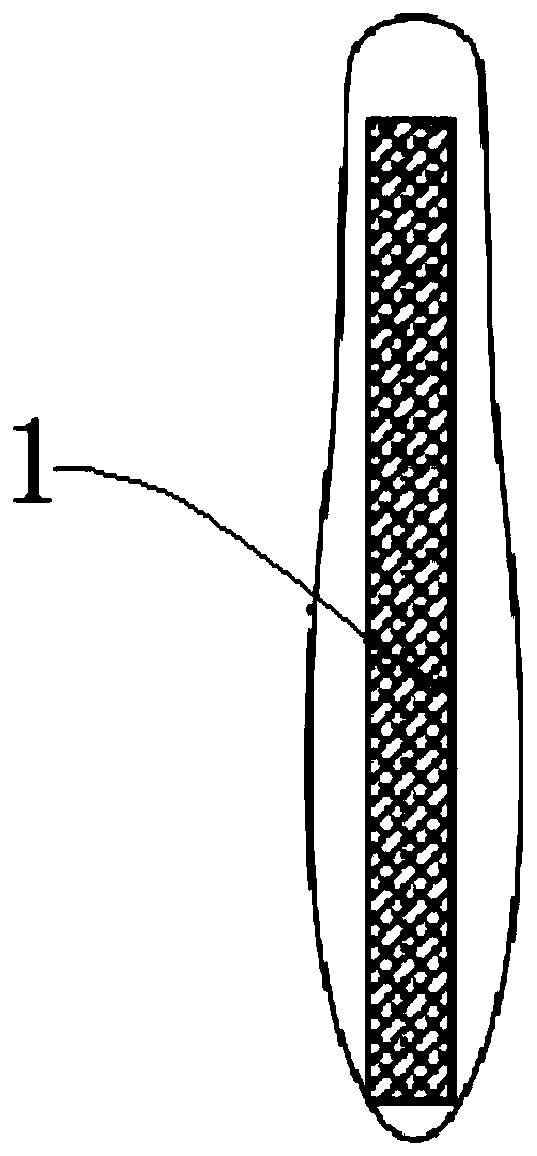

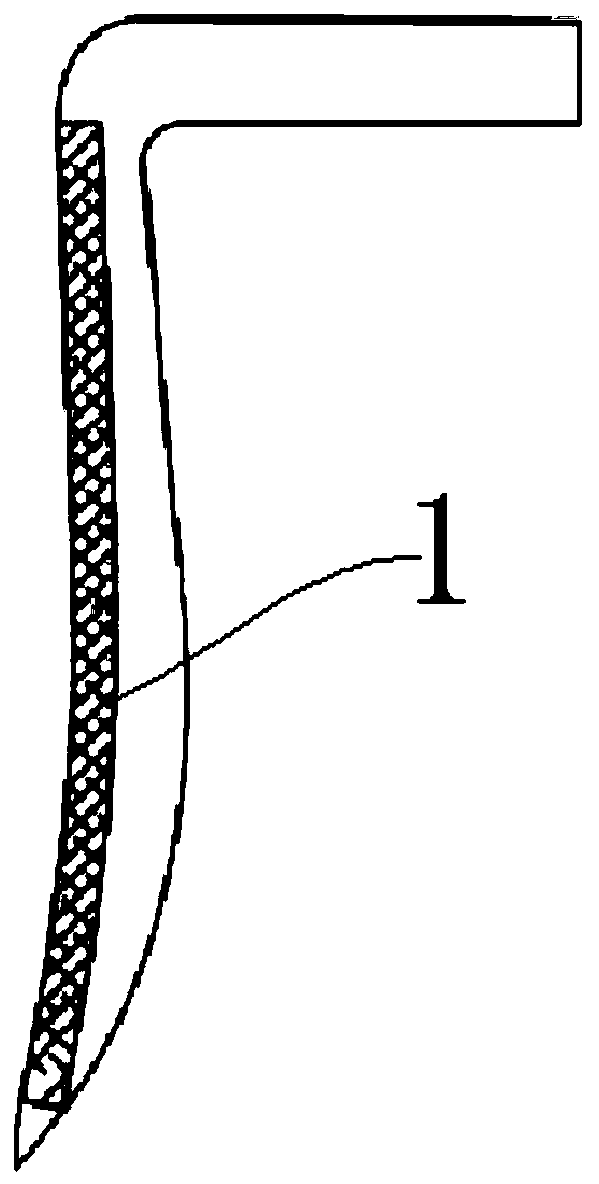

Composite nose bridge prosthesis manufacturing method

A compound type and nose bridge technology, applied in prosthesis, nose implants, medical science, etc., can solve the problems of prosthesis displacement, reduce the use effect of nose bridge prosthesis, light transmission, etc., and achieve the effect of improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for making a composite nose bridge prosthesis, comprising the following steps

[0025] Step 1: Sandblasting the surface of the mold cavity of a silicone rubber nose bridge prosthesis with grooves on the nose strap, so that the surface of the mold cavity has a certain roughness of 1-3 μm;

[0026] Step 2: Put the silicone rubber into the mold cavity in step 1 for vulcanization to make a prosthesis with a groove in the middle of the silicone rubber nose bridge. The surface roughness of the product is 1-3 μm;

[0027] Step 3: Cut the expanded polytetrafluoroethylene plate into pieces equal to the groove depth and shape of the silicone rubber prosthesis;

[0028] Step 4: Dissolve medical semi-solid silicone rubber in petroleum ether solvent to make it fully dissolved, and the viscosity is 700-800cP at room temperature;

[0029] Step 5: Apply the silicone rubber liquid with a certain viscosity prepared in step 4 evenly on the nasal dorsum groove of the silicone rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com