Double-sided medium-free printing air bubble film and preparation device and method thereof

A preparation device and technology of air bubble film, which is applied in the field of packaging materials, can solve the problems of poor pressure resistance and friction resistance, and low service life, and achieve the effect of firm adhesion, not easy to wear, and no deformation of characters or patterns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

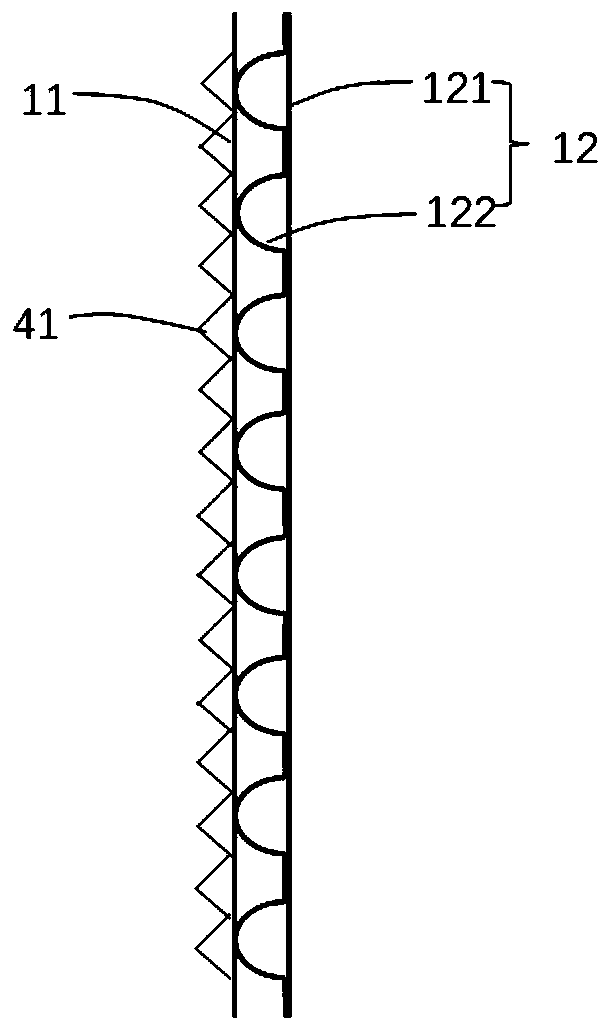

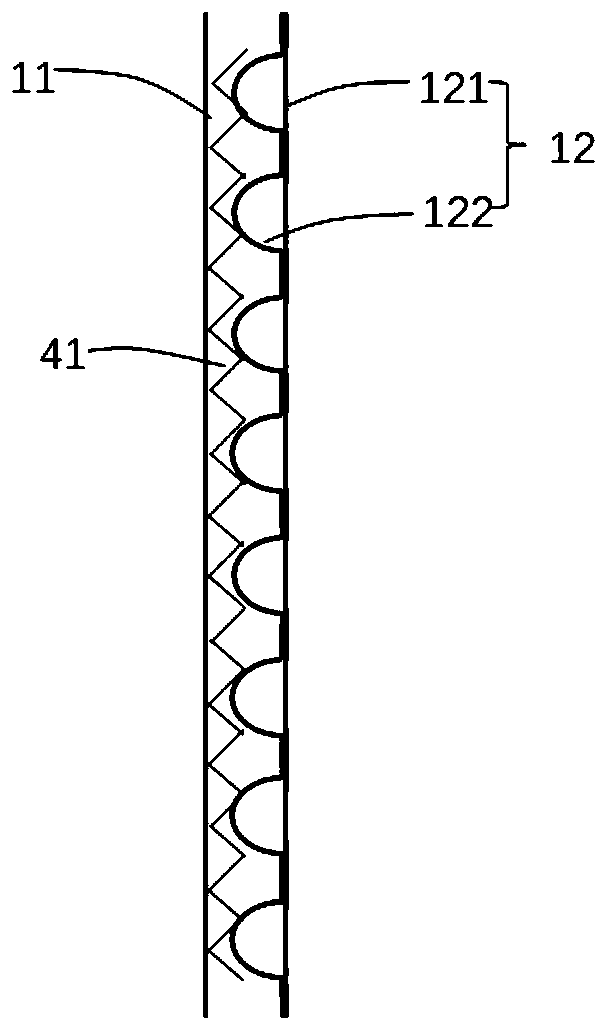

[0036] The double-sided non-media printing bubble film involved in this embodiment is produced by a double-sided non-media printing bubble film preparation device and its preparation method, and its main structure includes a first plane film 11, a second plane film 121, and a bubble film 122 and the printing layer 41, the bubble film 122 is located between the second plane film 121 and the first plane film 11, and the printing layer 41 is tightly adhered to the surface of the first plane film 11 without gaps; the bubble film 122 has several protrusions on the surface Thin film structure, several protrusions have the same protrusion direction, the height of the protrusions is ≥0.5mm, the border spacing between the protrusions is ≥0.01mm, and the shapes of the protrusions are circle, square, heart, rhombus, five-pointed star Shape, ellipse, polygon and irregular shape or a combination of several, the film structure thickness of the bubble film 122 is ≥0.002mm; the second plane fi...

Embodiment 2

[0062] This embodiment is the preparation device for double-sided medialess printing air bubble film involved in embodiment 1. Its main structure includes a bonding guide roller 1, a second pulling roller 2, a first pulling roller 3, a winding device 4, a first unwinding The roll device 5, the second unwinding device 6, the heating device 71 and the constant temperature water circulation system; the bonding guide roller 1 and the first traction roller 3 are set separately, and the gap between the bonding guide roller 1 and the first traction roller 3 is formed The bonding mouth of the first plane film 11 and the double-layer single-sided air bubble film 12, the gap size between the bonding guide roll 1 and the first traction roll 3 is effective with the first plane film 11 and the double-layer single-side air bubble film 12. The overall thickness formed by bonding matches. The bonding guide roller 1 is a circular cross-section with a smooth metal roller structure on the outer s...

Embodiment 3

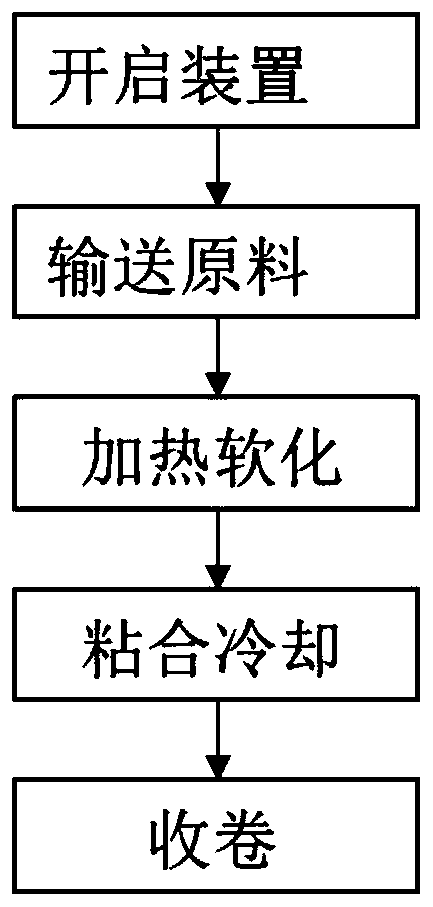

[0072] This embodiment is the preparation method of the double-sided non-media printing air bubble film involved in Example 1, which is realized in the double-sided non-media printing air bubble film preparation device. The main process steps include:

[0073](1) Opening device: start the first unwinding device 5, the second unwinding device 6, the bonding guide roller 1, the first traction roller 3, the second traction roller 2, the constant temperature water circulation system, the heating device 71 and the winding device 4; the first unwinding device 5 is located upstream of the bonding guide roller 1; the second unwinding device 6 is located upstream of the first traction roller 3; the upstream gap between the bonding guide roller 1 and the first traction roller 3 forms the first The bonding mouth of a plane film 11 and double-layer single-sided air bubble film 12; The second traction roll 2 is positioned at the downstream angle of bonding guide roll 1 and the first tractio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com