High-performance activated carbon purification filter element and preparation method thereof

An activated carbon and high-performance technology, applied in chemical instruments and methods, other chemical processes, chemical/physical processes, etc., can solve the problems of high production cost, inconvenient large-scale continuous and rapid production, high energy consumption, etc., and achieve enhanced porosity and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

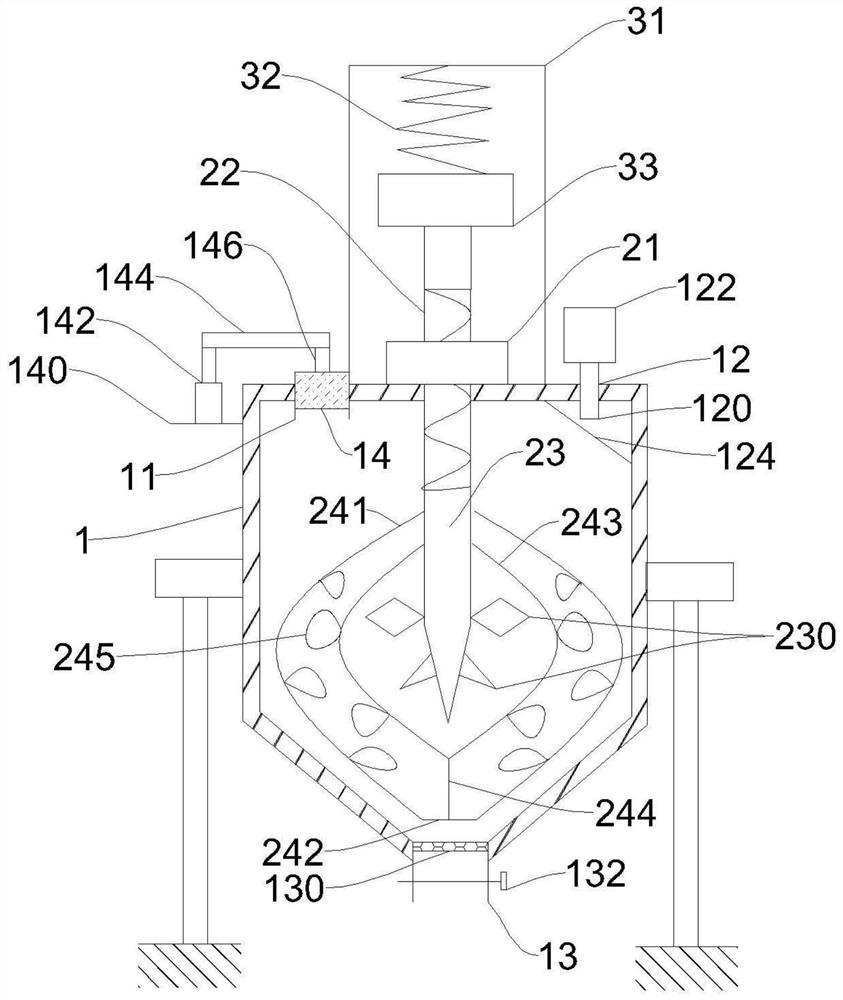

Image

Examples

Embodiment 1

[0038] The invention provides a high-performance activated carbon purification filter element, comprising the following raw materials: 70 parts by weight of coconut shell activated carbon, 10 parts by weight of ultra-high polymer binder, 5 parts by weight of vermiculite, and 10 parts by weight of zeolite molecular sieve.

[0039] The present invention also provides a high-performance activated carbon purification filter element and a preparation method thereof, comprising the following steps:

[0040] Step 1. After the above-mentioned coconut shell activated carbon, ultra-high polymer binder, vermiculite, and zeolite molecular sieve of the above-mentioned weight portion are respectively ground and sieved to 250 meshes, mixed and stirred for 1 h and preheated to 45° C. to obtain mixed powder. ;

[0041] Step 2, the mixed powder is extruded and cooled to room temperature, and then cut to obtain a high-performance activated carbon purification filter element.

[0042] Wherein, t...

Embodiment 2

[0047] The invention provides a high-performance activated carbon purification filter element, comprising the following raw materials: 70 parts by weight of coconut shell activated carbon, 10 parts by weight of ultra-high polymer binder, 5 parts by weight of vermiculite, and 10 parts by weight of zeolite molecular sieve.

[0048] The present invention also provides a high-performance activated carbon purification filter element and a preparation method thereof, comprising the following steps:

[0049] Step 1. After the above-mentioned coconut shell activated carbon, ultra-high polymer binder, vermiculite, and zeolite molecular sieve of the above-mentioned weight portion are respectively ground and sieved to 250 meshes, mixed and stirred for 1 h and preheated to 45° C. to obtain mixed powder. ;

[0050] Step 2, the mixed powder is extruded and cooled to room temperature, and then cut to obtain a high-performance activated carbon purification filter element.

[0051] Wherein, t...

Embodiment 3

[0056] The invention provides a high-performance activated carbon purification filter element, comprising the following raw materials: 70 parts by weight of coconut shell activated carbon, 10 parts by weight of ultra-high polymer binder, 5 parts by weight of vermiculite, and 10 parts by weight of zeolite molecular sieve.

[0057] The present invention also provides a high-performance activated carbon purification filter element and a preparation method thereof, comprising the following steps:

[0058] Step 1. After the above-mentioned coconut shell activated carbon, ultra-high polymer binder, vermiculite, and zeolite molecular sieve of the above-mentioned weight portion are respectively ground and sieved to 250 meshes, mixed and stirred for 1 h and preheated to 45° C. to obtain mixed powder. ;

[0059] Step 2, the mixed powder is extruded and cooled to room temperature, and then cut to obtain a high-performance activated carbon purification filter element.

[0060] Wherein, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com