Hydrothermal rock breaking cracking device, detonating network and directional cutting method thereof

A technology of detonation network and rock-breaking device, which is applied in blasting, blasting barrels, earthwork drilling and mining, etc. It can solve the problems of easy explosion risk, high pressure, and hidden safety hazards, so as to increase the rock-breaking effect and reduce vibration disturbance and noise , Reduce the effect of rock debris dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

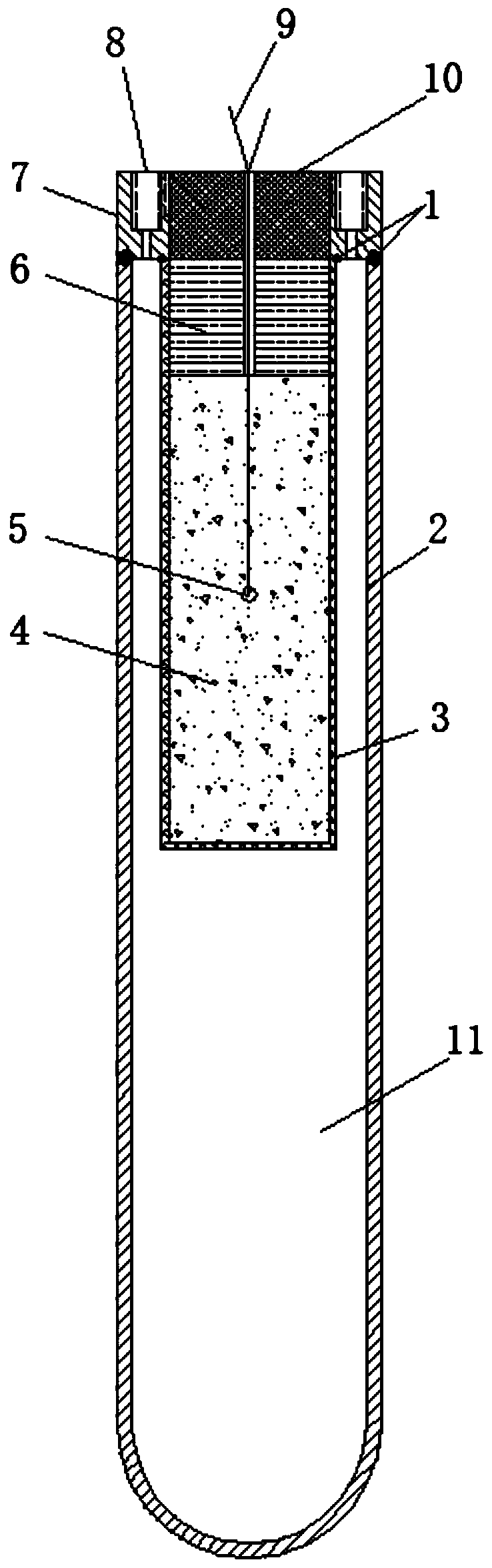

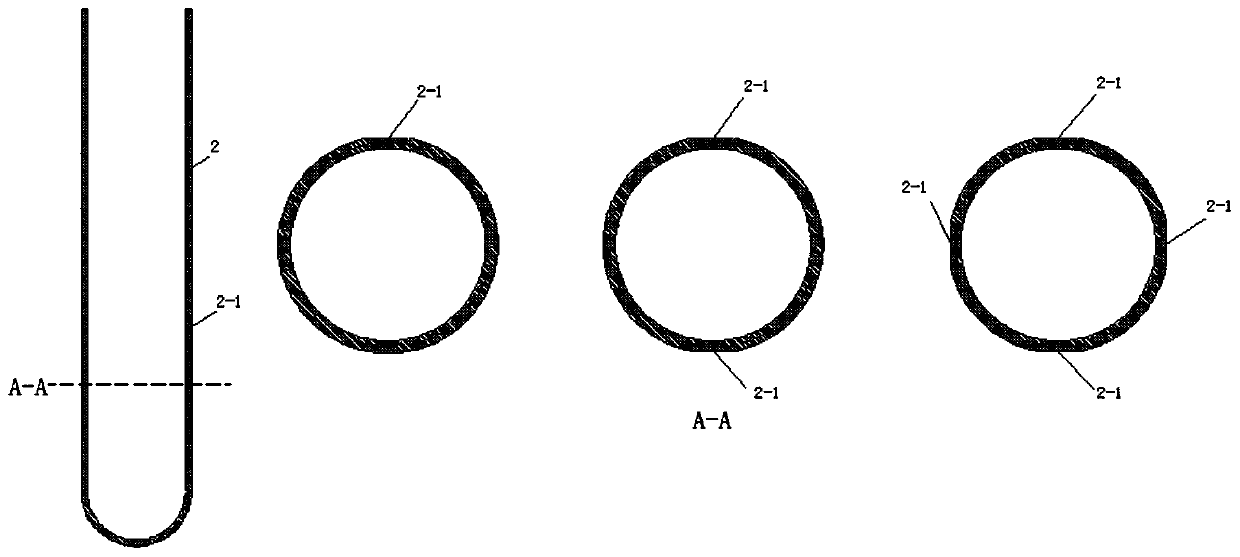

[0038] Such as figure 1 As shown, a hydrothermal rock-breaking fracturing device includes a directional cracker 2, an ionic aqueous solution 11 is housed in the directional cracker 2, an inner liner heat pipe 3 is fixed inside the directional cracker 2, The liner heat pipe 3 includes a plug 10, a heat insulating component 6 and an energy-gathering agent 4 from top to bottom. Among them, the other end of the resistance wire 5 is connected to an electric wire 9, and the electric wire 9 is connected to an electric exciter, and the electric exciter is connected to a mobile power supply. The connection between the directional cracker 2 and the inner tank heat pipe 3 is provided with a water injection end 7, and the middle and lower end of the directional cracker 2 is provided with a weak gap 2-1. The inner liner heat pipe 3 has good thermal conductivity, and directly transfers the heat released by the combustion of the energy gathering agent 4 to the ion aqueous solution 11, and t...

Embodiment 2

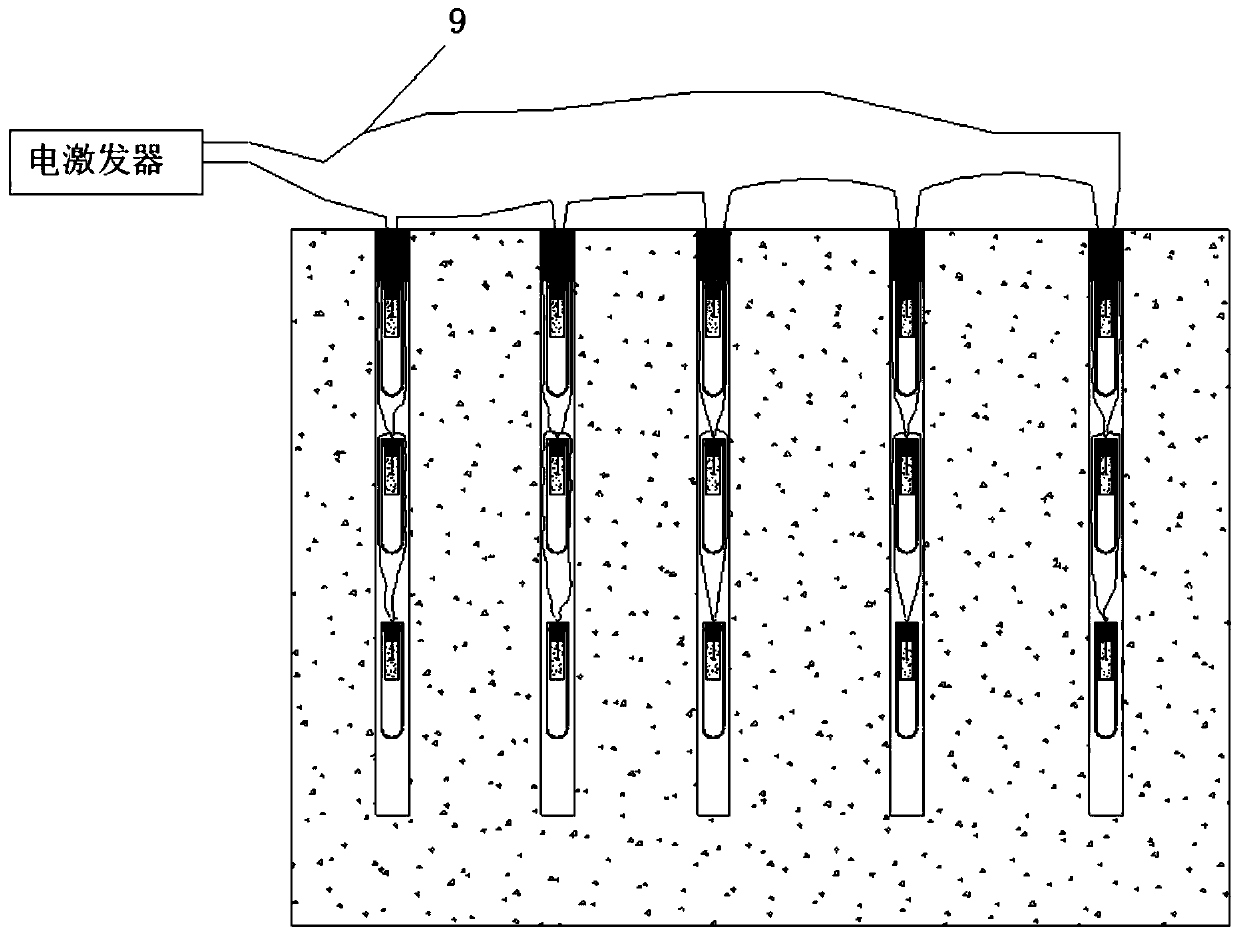

[0043] Such as image 3As shown, a hydrothermal rock-breaking detonation network includes a number of hydrothermal rock-breaking fracturing devices described in Embodiment 1. A single-hole device network formed in parallel, the single-hole device network is placed in a single borehole, Single-hole device nets are placed in different boreholes, and different single-hole device nets are connected in series to form a complex detonation network. The number of hydrothermal rock-breaking fracturing devices connected in series and parallel in the detonation network can be determined according to the actual site survey. For example, 2-3 hydrothermal rock-breaking devices are usually installed in a single borehole, and complex terrain can also be connected in parallel. Multiple hydrothermal rock-breaking and fracturing devices. When connecting in series and parallel, directly connect the electric wire 9 reserved on the hydrothermal rock-breaking fracturing device for series and parall...

Embodiment 3

[0048] A directional cutting method for hydrothermal rock breaking, comprising the following steps:

[0049] S1: Water injection of hydrothermal rock breaking device: inject ionized aqueous solution 11 into directional cracker 2 through water injection port 8, and close water injection port 8 after directional cracker 2 is filled with ionized aqueous solution 11;

[0050] S2: Series-parallel connection of the hydrothermal rock-breaking device: according to the site geological conditions, connect the wires 9 on the hydrothermal rock-breaking device in series and parallel;

[0051] S3: Hole drilling, orientation, and hole sealing: put the series-parallel connected directional crackers 2 into several drill holes, adjust the direction of the weak gap 2-1 of the directional cracker 2 according to the requirements of the directional cutting direction, and seal the holes. hole;

[0052] S4: connect to the detonation network, and detect the connectivity;

[0053] S5: Security alert,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com