Preparation method of ultrahigh-strength pure aluminum

An ultra-high-strength, pure aluminum technology, applied in the direction of metal extrusion control equipment, metal rolling, manufacturing tools, etc., can solve the problem of sacrificing the plasticity of aluminum alloys, so as to improve the strength, the plasticity will not be significantly weakened, and the strength will be improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a method for preparing ultra-high-strength pure aluminum, comprising the following steps:

[0023] placing as-cast pure aluminum in an equal-channel corner mold for equal-channel corner extrusion deformation to obtain an extruded billet; the corner angle of the equal-channel corner mold is 90°;

[0024] immersing the extruded billet in liquid nitrogen for cooling, and rolling the cooled billet to obtain a rolled billet;

[0025] The process of cooling and rolling is repeated until the billet is thinned to the target thickness after the last rolling pass to obtain ultra-high-strength pure aluminum.

[0026] In the invention, cast pure aluminum is placed in an equal-channel corner mold for equal-channel corner extrusion deformation to obtain an extruded billet.

[0027] The present invention has no special requirements on the source of the as-cast pure aluminum, which can be cast by casting methods known in the art or commercially available product...

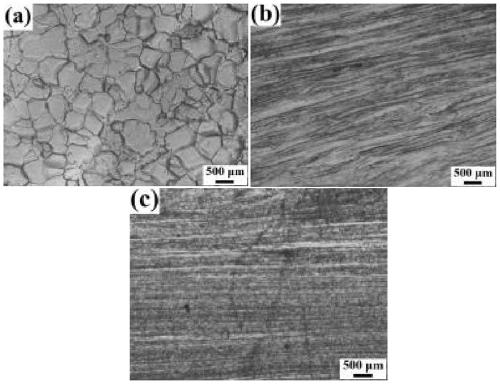

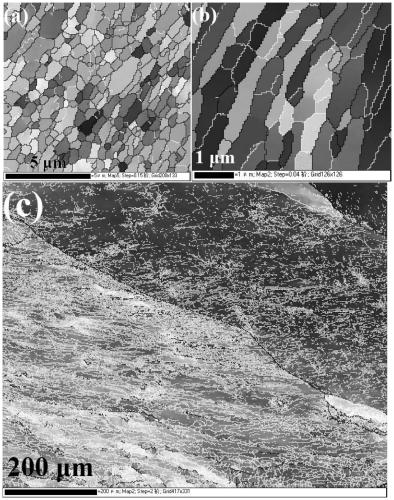

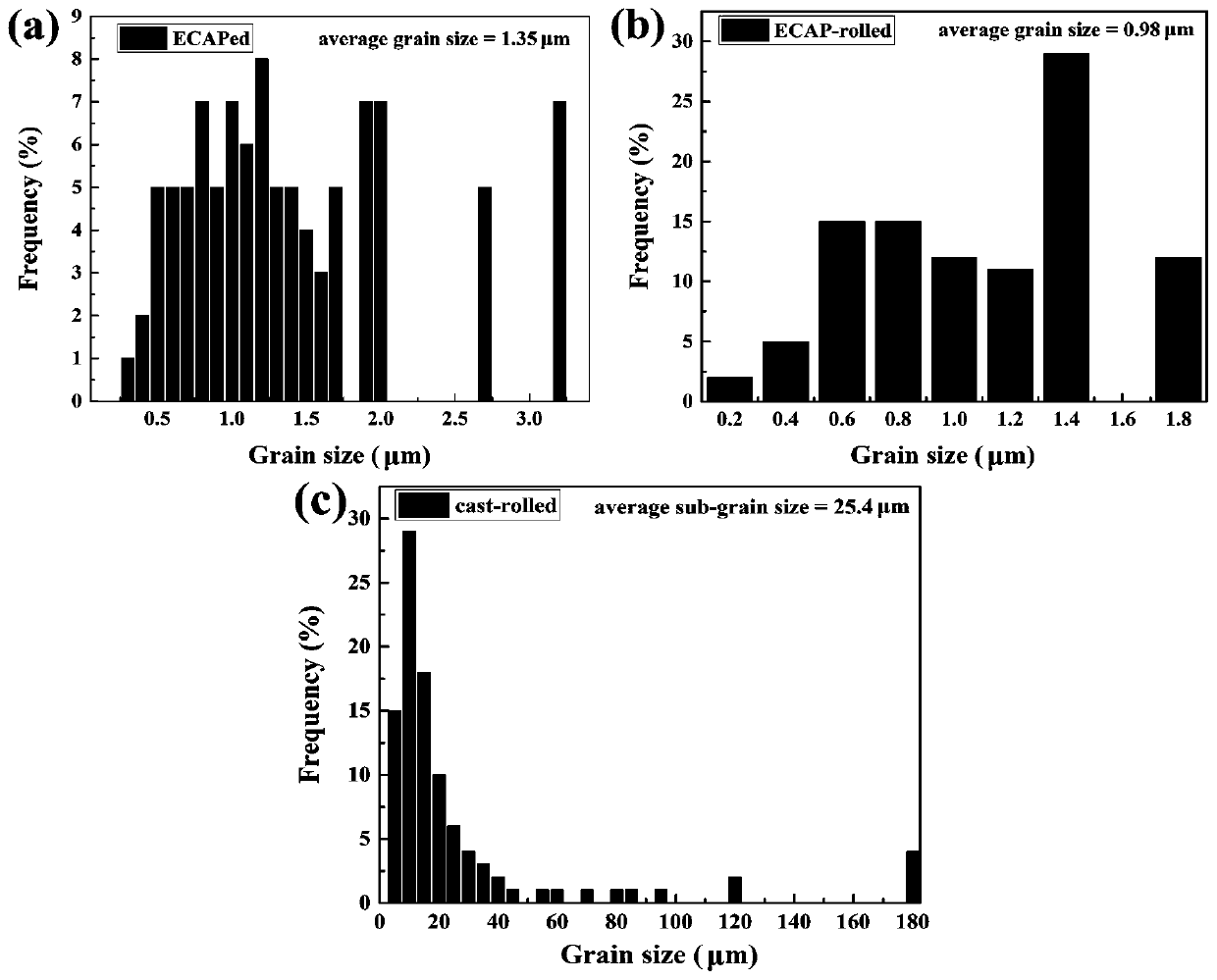

Embodiment 1

[0040] The cast industrial pure aluminum (purity is 99.97%) is processed into a columnar specimen of 19.5×19.5×40mm by wire cutting, and the cut specimen is subjected to surface pretreatment to obtain a clean surface. The clean surface of the specimen and etc. The inner surface of the channel corner mold is coated with lubricant, and then the cut specimen is placed in the equal channel corner mold, and pressure is applied at room temperature for 16 consecutive passes of ECAP extrusion, and the sample is rotated between adjacent extrusion passes 90°.

[0041] Cut the test piece after ECAP into a 40×19.5×4mm plate by wire, soak the plate in liquid nitrogen for 5 minutes to ensure that the sample reaches -160°C, and then pass it through a roll (diameter 150mm) at room temperature at 10r min -1 The speed of rolling is fast, and the thickness of the plate is reduced by about 5% after each pass of rolling. Immediately after rolling, the sample is cooled again in liquid nitrogen. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com