Breeding solid waste treatment device

A technology of treatment device and treatment tank, which is applied in animal husbandry wastewater treatment, biological sludge treatment, etc., can solve the problems of reduced biogas output, intermittent biogas, limited manure output, etc., and achieve the effect of increasing effective output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

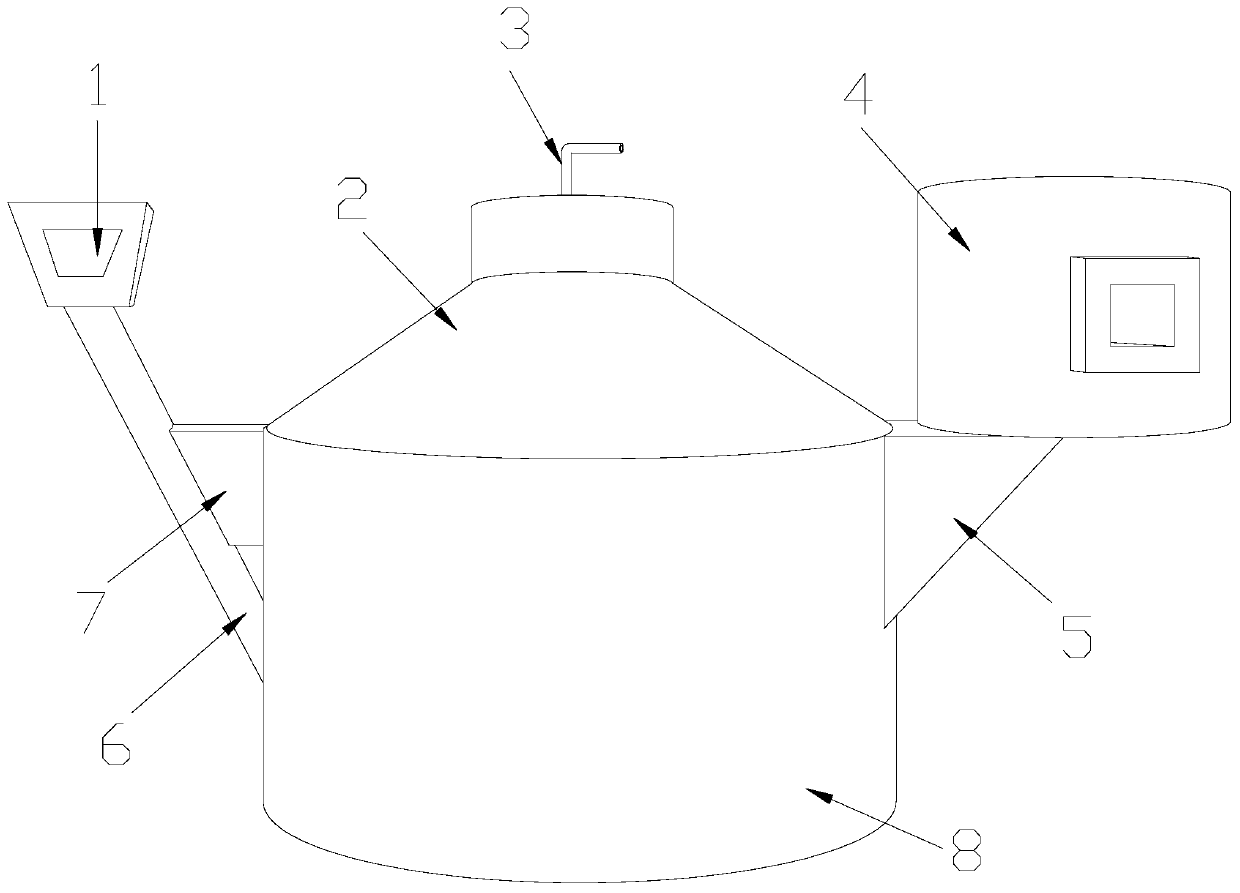

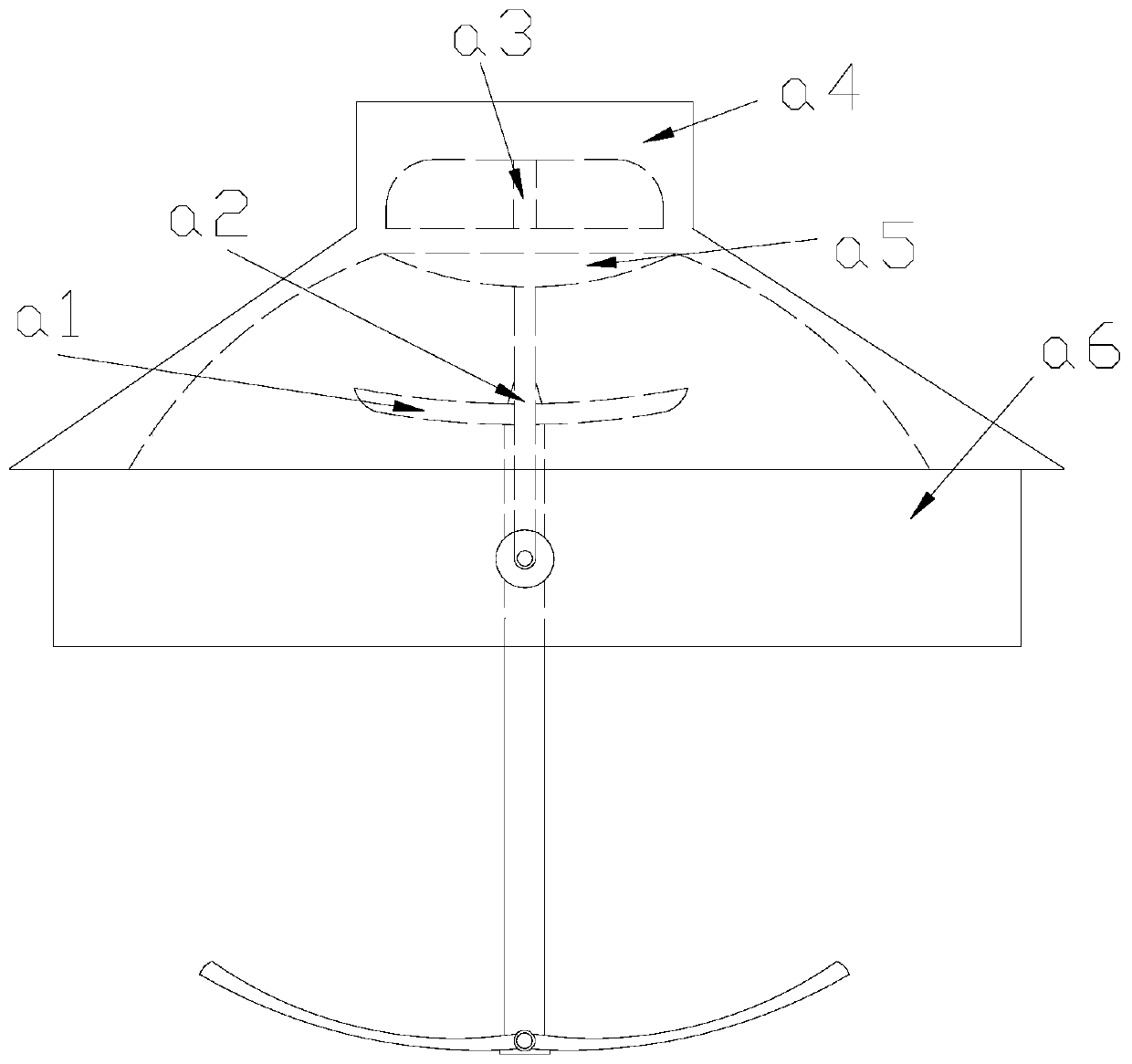

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The invention provides a farming solid waste treatment device, the structure of which includes a feed box 1, a solid waste exhaust turning device 2, an exhaust pipe 3, a diagonal flow box 4, a dislocation diversion block 5, an introduction pipe 6, a lateral Reinforcing rib 7, breeding solid waste fermentation treatment tank 8, the bottom end of the feed box 1 is welded to the inlet pipe 6, the lateral reinforcing rib 7 is fixed at the middle position on the right side of the inlet pipe 6, and the diagonal flow box 4. The dislocation guide block 5 is fixedly connected with the culture solid waste fermentation treatment tank 8, and the bottom end of the solid waste exhaust turning device 2 is installed in the culture solid waste fermentation treatment tank 8 by embedding. The trachea 3 is fixedly embedded in the top of the solid waste exhaust turning device 2 .

[0032] The solid waste exhaust turning device 2 i...

Embodiment 2

[0040] as attached figure 1 to attach Figure 8 Shown:

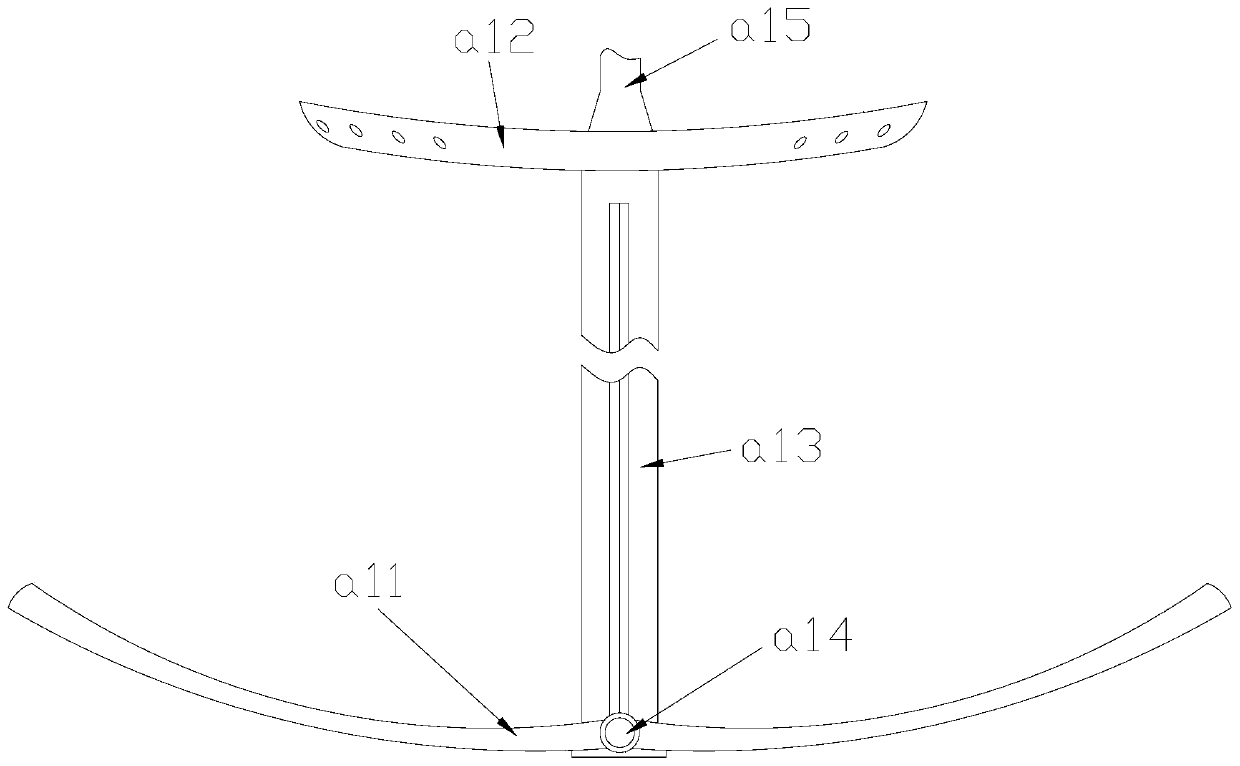

[0041] The present invention provides a farming solid waste treatment device, wherein the suction plate a51 includes warp piece a511, soft joint piece a512, movable piece a513, pulling bar a514, stamped inner conduit a515, and the warp piece a511 is connected with the movable piece The pieces a513 are fixedly connected together, the movable pieces a513 are connected to each other through the flexible piece a512, the pulling strip a514 is arranged on the back of the movable piece a513, and the flexible piece a512 is fixedly connected with the outer guide tube a3 At the same time, the stamped inner conduit a515 is located below the warp a511, and when the movable piece a513 is sucked by the biogas above, its suction force can pull the flexible piece a512 to rotate upwards against the movable piece a513, and can pull and pull Section a514.

[0042] Wherein, each group of said rubber strips a134 has two sets, and they ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com