Method and device for purifying aluminum nitride powder by adopting PVT method

A technology of aluminum nitride and powder, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of equipment becoming hard and brittle, prone to cracks or defects, and limited loading quality, so as to increase the heating uniformity, increase effective output, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] The aluminum nitride powder is purified by the purification method of the first embodiment of the present invention, and its specific implementation process is as follows:

[0093] Step 1. Heat treatment of aluminum nitride powder

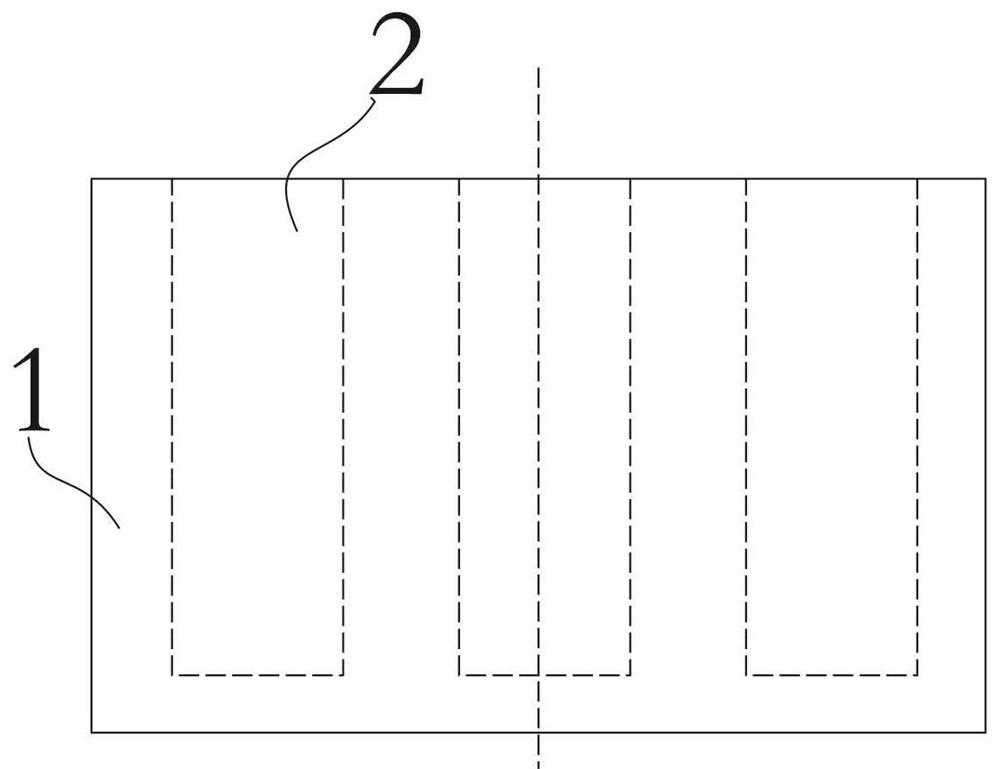

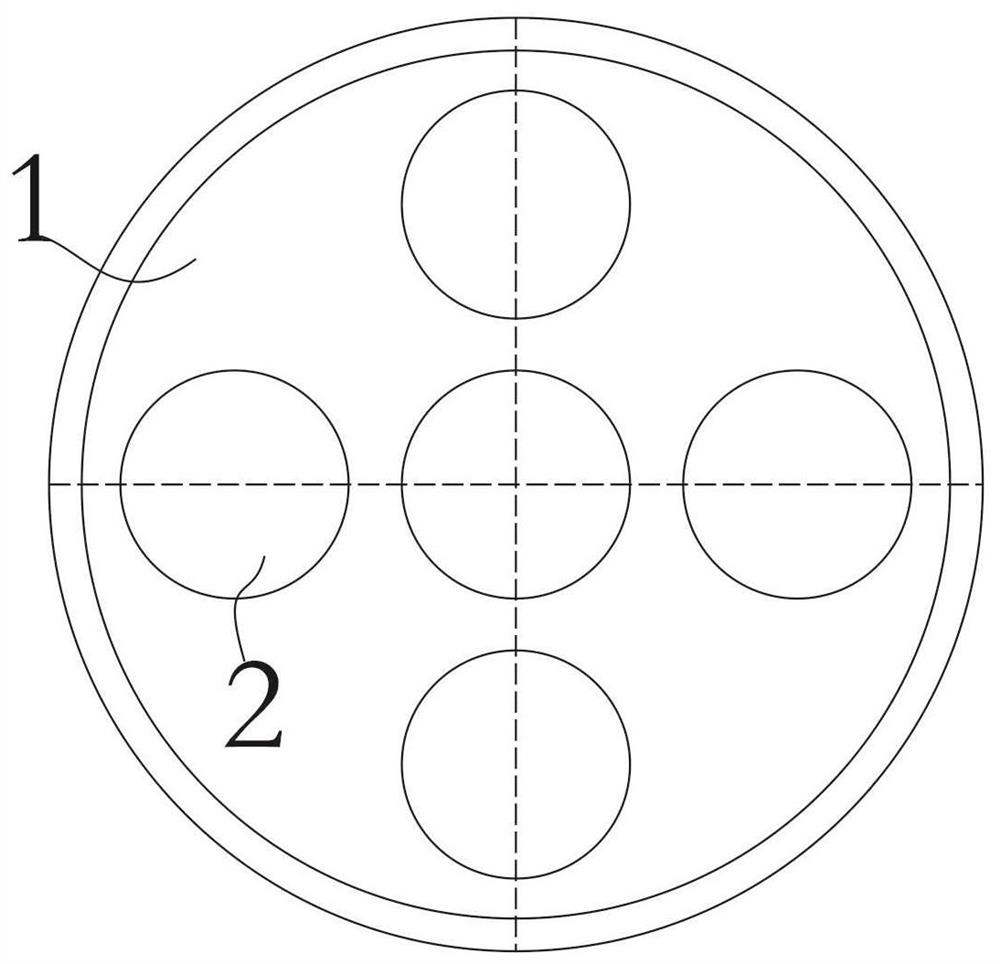

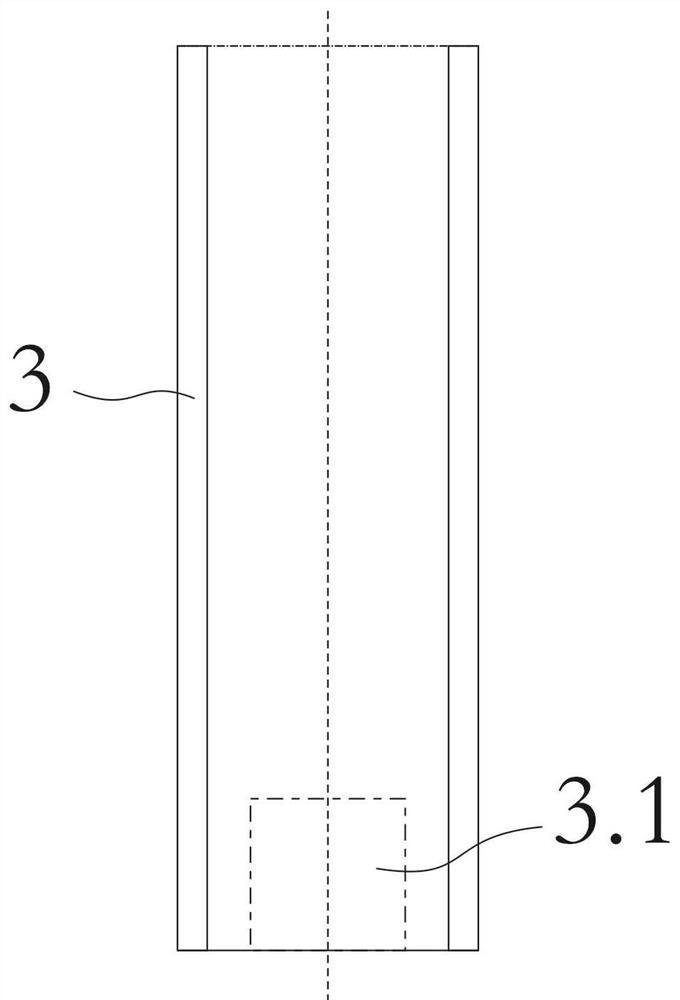

[0094] Put the aluminum nitride powder into a tantalum carbide crucible (that is, a metal crucible) with an inner diameter of 44mm and a height of 165mm, a total of 5 tantalum carbide crucibles, and the charging is about 582g, and the total charging per cubic centimeter is about 0.45g , and keep the upper surface of the material about 10mm away from the top cover of the tantalum carbide crucible. After that, cover the top cover of the tantalum carbide crucible and the top cover of the graphite crucible in turn, the graphite crucible has a five-hole structure, and a hard felt crucible is used for physical isolation between the graphite crucible and the tantalum carbide crucible;

[0095] Put the graphite crucible covered with the insulation ...

Embodiment 2

[0105] The aluminum nitride powder is purified by the purification method of the second embodiment of the present invention, and its specific implementation process is as follows:

[0106] Step 1. Prefabricated cylindrical aluminum nitride powder

[0107] Using plastic cylinders, cylindrical aluminum nitride is prefabricated by mechanical extrusion. Its diameter is 2 mm lower than that of a tungsten crucible (ie, a metal crucible), and its height is 10 mm lower than that of the tungsten crucible, and the density of the prefabricated cylindrical aluminum nitride is about 1.2 g per cubic centimeter of mass.

[0108] Step 2, high temperature impurity removal

[0109] Put the prefabricated cylindrical aluminum nitride in the above-mentioned step 1 into a tungsten crucible with an inner diameter of 44mm and a height of 165mm, a total of 5 tungsten crucibles, charging about 1552g, so that the upper surface of the material is kept about 10mm from the top cover of the tungsten crucib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com