High-power white light LED with good heat dissipation and manufacturing method thereof

A manufacturing method and high-power technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low thermal stability of mixed organic glue materials, uneven angular distribution of white light correlated color temperature, and yellow circles. Taking into account heat transfer and heat storage capacity, eliminating edge chromatic aberration effect, and increasing the effective output of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

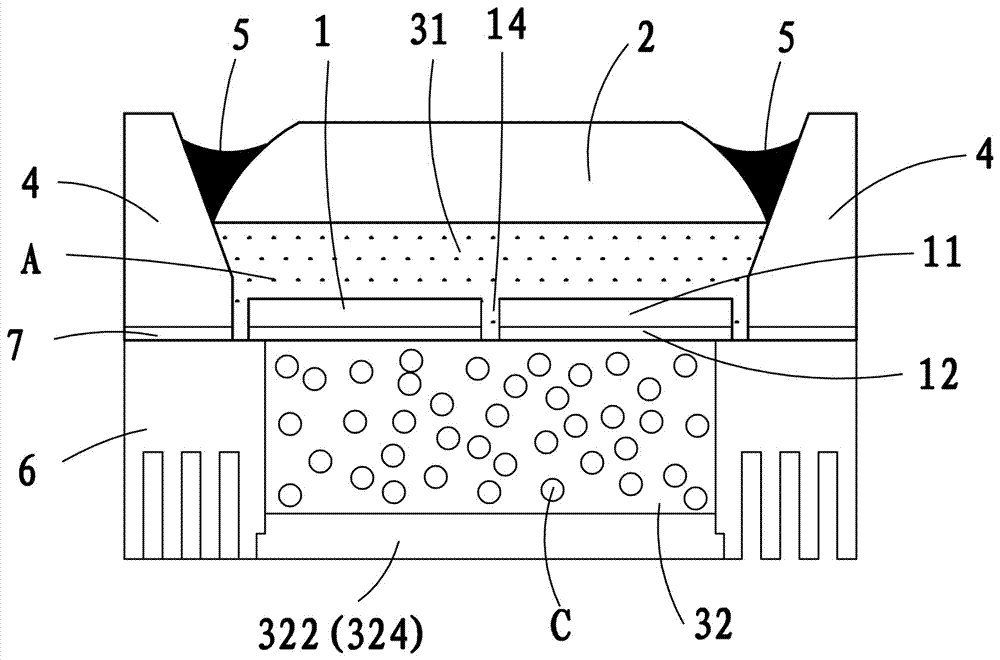

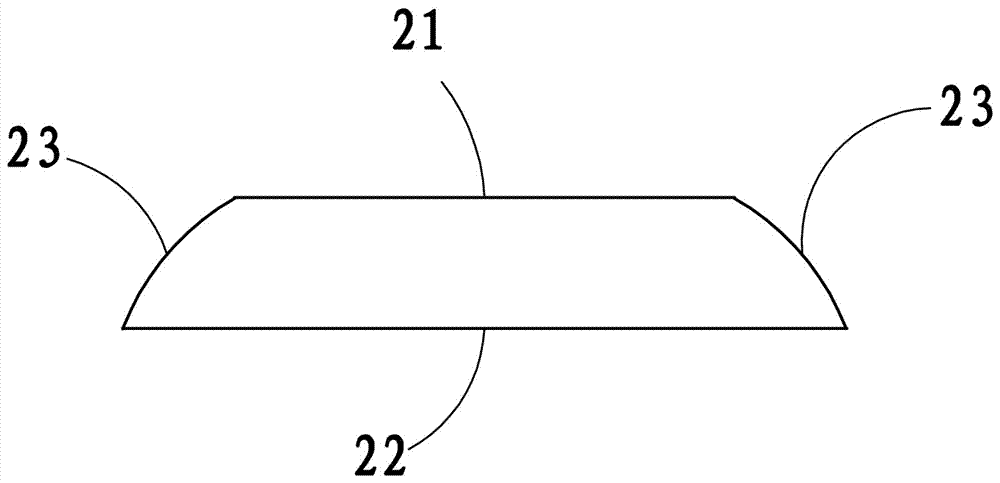

[0038] Such as Figure 1 to Figure 5 As shown, the high-power white LED with good heat dissipation of the present invention includes a COB chip module 1 , a transparent ceramic fluorescent cover 2 , a reflector 4 , an upper liquid-filled cavity 31 , a lower liquid-filled cavity 32 and a radiator 6 .

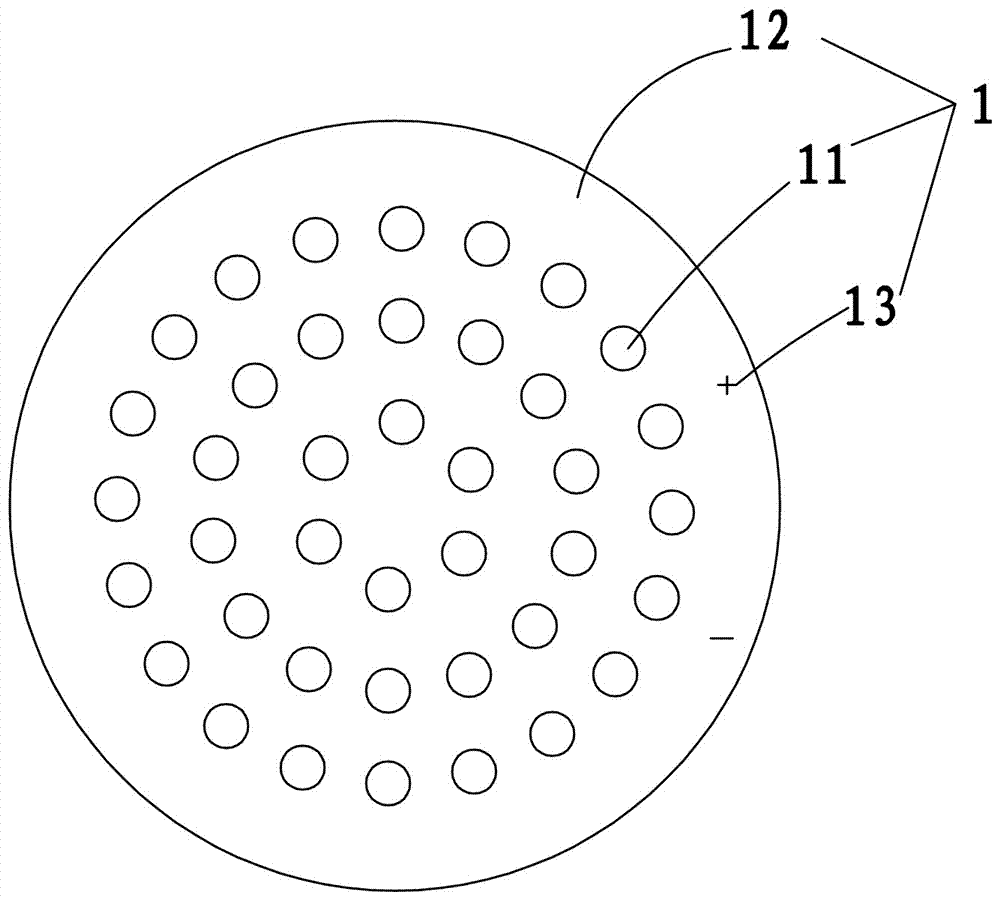

[0039] Such as figure 1 and figure 2 As shown, the COB chip module 1 is a heat dissipation substrate 12 packaged with multiple blue LED chips 11; wherein, the blue LED chips 11 of the present invention can reach more than 100, which can realize real high power; the COB chip The module 1 is located at the bottom of the reflective cup 4 and has a liquid outlet 14 in the middle; the positive and negative electrodes 13 of the COB chip module 1 are electrically connected to the external positive and negative electrodes respectively. In a preferred embodiment, the blue LED chips 11 packaged on the COB chip module 1 are arranged in an array structure, such as a circular array, and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| luminous flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com