Novel sewage suction purification vehicle

A purifying vehicle and a new type of technology, applied in the field of environmental sanitation, can solve the problem that the harmless treatment of septic tanks cannot completely realize the comprehensive treatment and recycling of septic tanks, and achieve the effect of efficient utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

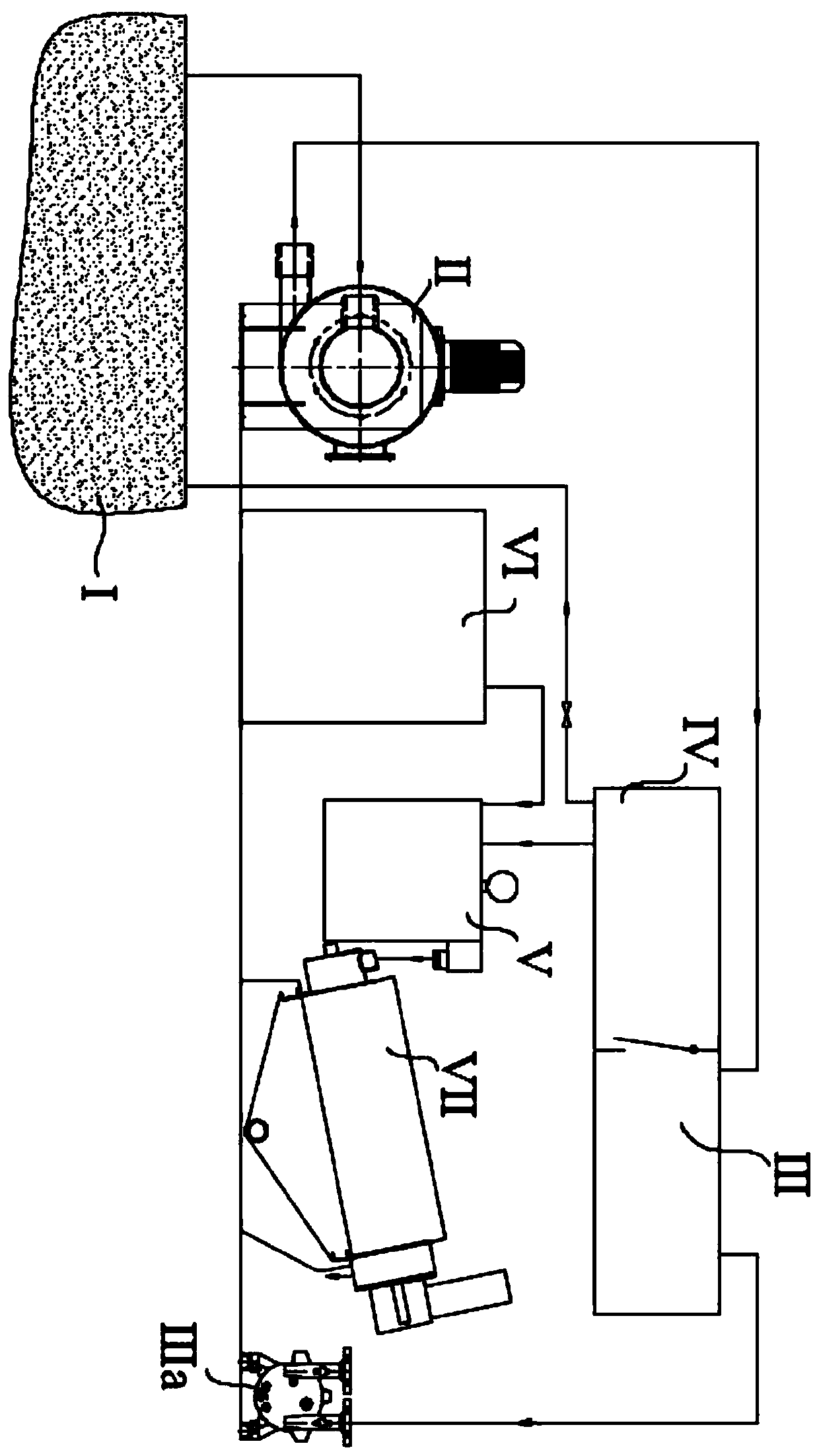

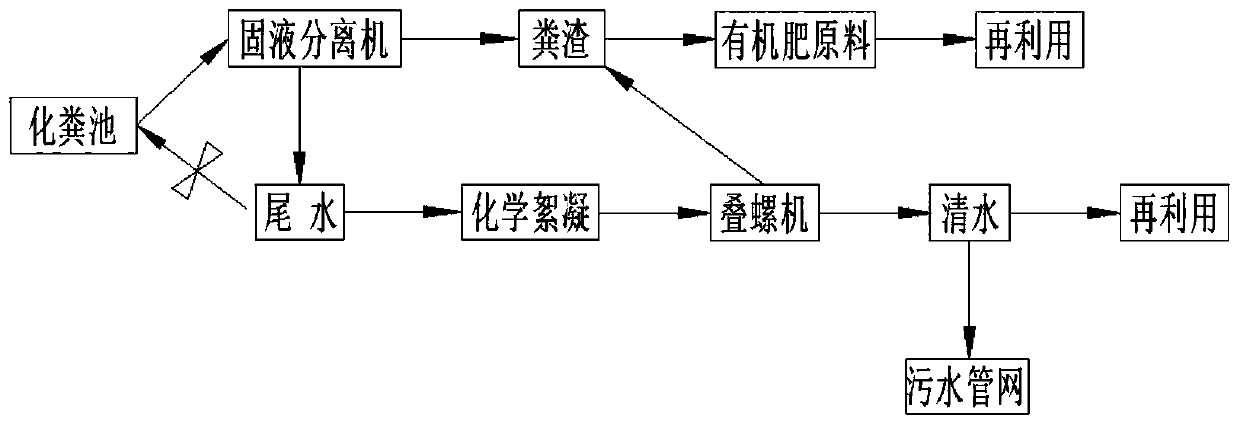

[0023] Such as figure 1 As shown, a new type of sewage suction and purification vehicle is disclosed in this embodiment, which includes a vacuum tank III and a sewage tank IV installed on a second-type chassis, a solid-liquid separator II connected to the vacuum tank III, and a solid-liquid separator II connected to the vacuum tank III. The coagulation tank V connected to the sewage tank IV and the screw stacker VII used for solid-liquid separation of the feces in the coagulation tank V that have reacted with chemicals, the vacuum tank III and the sewage tank There is a transition hole between IV. The screw stacker is an industrial equipment used for sludge dewatering treatment, and its full name is a screw stacker sludge dewaterer.

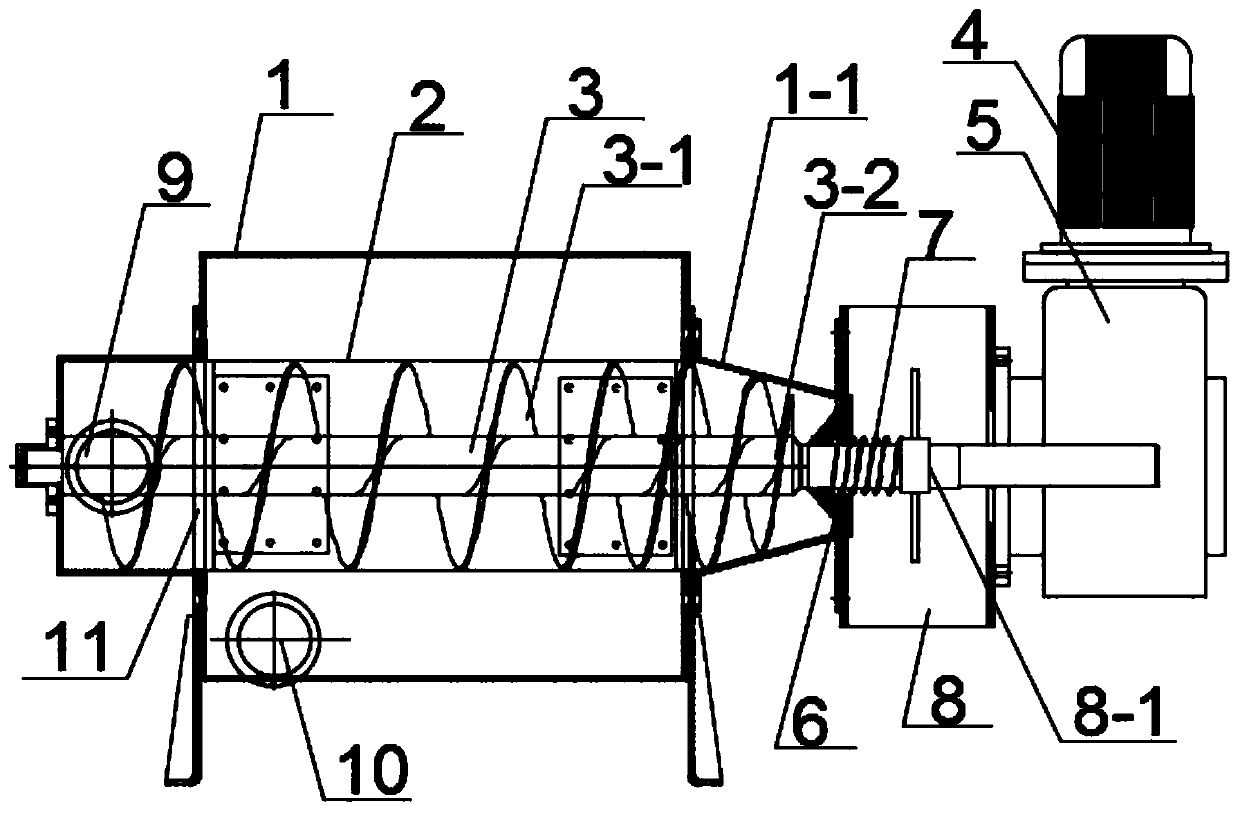

[0024] Such as Figure 3-5 As shown, the solid-liquid separator II includes a supporting shell, a fecal liquid feed pipe and a filtered water outlet pipe opened on the supporting shell, and is installed in the supporting shell for conveying the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com