Carbon fiber reinforced ceramic-based composite material and preparation method of pyrolytic carbon interface layer

A composite material and carbon fiber technology, which is applied in the field of carbon fiber reinforced ceramic matrix composite materials and pyrolytic carbon interface layer preparation, can solve the problems of mismatching properties between the reinforcement and the matrix, and improve the interface bonding state and microstructure. Damaged, Mitigated Effects of Mismatched Physical and Chemical Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a pyrolytic carbon interface layer of a carbon fiber reinforced ceramic matrix composite material, the implementation steps are as follows:

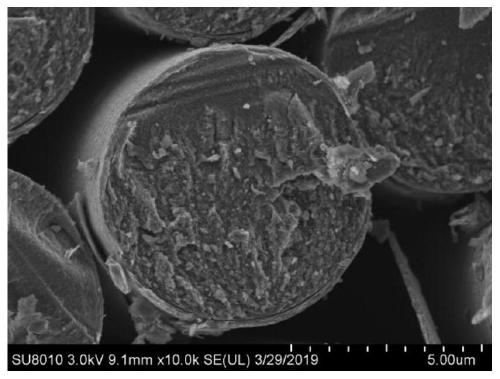

[0029] Firstly, carbon fiber reinforcement is formed: needle-punched weaving process, one layer of T7006K non-weft fabric and one layer of T70012K net tire are alternately laminated and continuously needle-punched to form a whole fabric, and the non-weft fabric adopts 0° / 90° lamination.

[0030] Vacuum debinding of carbon fiber reinforcements. Put the carbon fiber reinforced body into a high-temperature furnace for debinding treatment in a vacuum state, the treatment temperature is 1040°C, and the treatment time is 1.5h.

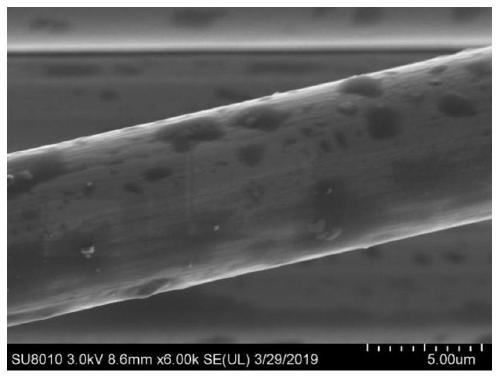

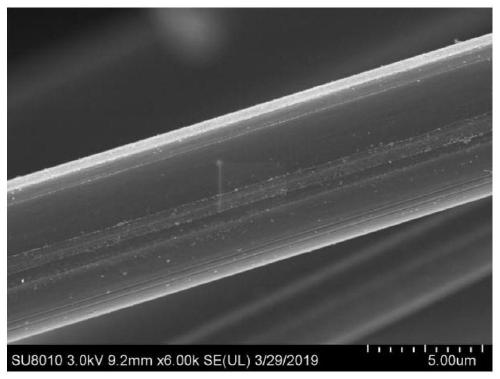

[0031] Deposit a pyrolytic carbon interface layer. Put the carbon fiber reinforcement after the above treatment into a chemical vapor deposition furnace, and deposit the pyrolytic carbon interface layer according to the following process conditions. The deposition temperature is 950°C, th...

Embodiment 2

[0035] A method for preparing a pyrolytic carbon interface layer of a carbon fiber reinforced ceramic matrix composite material, the implementation steps are as follows:

[0036] Firstly, the carbon fiber reinforced body is formed. Using acupuncture weaving technology, one layer of T7006K non-weft fabric and one layer of T70012K net tire are alternately laminated and continuously needled to form a whole fabric, and the non-weft fabric adopts 0° / 90° lamination.

[0037] Vacuum debinding of carbon fiber reinforcements. Put the carbon fiber reinforced body into a high-temperature furnace for debinding treatment in a vacuum state, the treatment temperature is 950°C, and the treatment time is 2h.

[0038] Deposit a pyrolytic carbon interface layer. Put the carbon fiber reinforcement after the above treatment into a chemical vapor deposition furnace, and deposit the pyrolytic carbon interface layer according to the following process conditions. The deposition temperature is 970°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com