Method for recovering chloroform and hydrogen chloride in production process of methyl isocyanate

A technology for the production process of methyl isocyanate, which is applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, chemical instruments and methods, etc., can solve problems such as poor recovery effect, and achieve the effect of simple operation and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment discloses a method for recovering chloroform and hydrogen chloride in the production process of methyl isocyanate, which comprises the following steps:

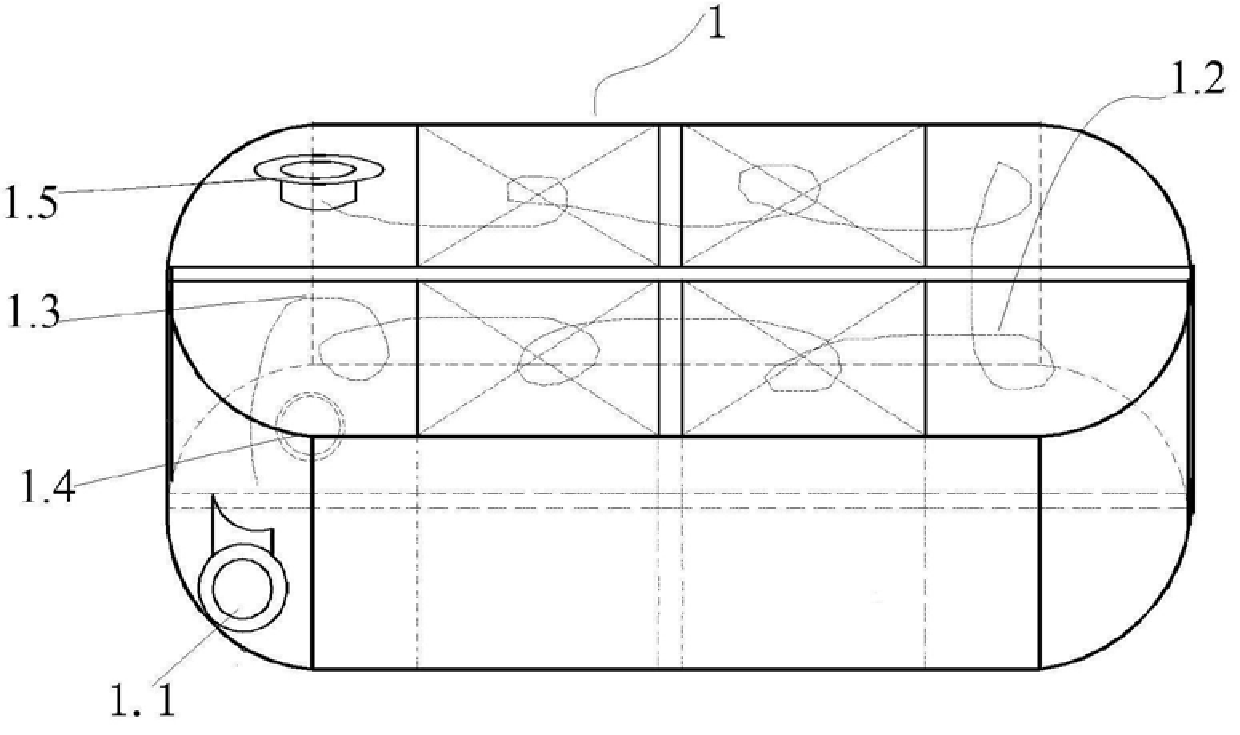

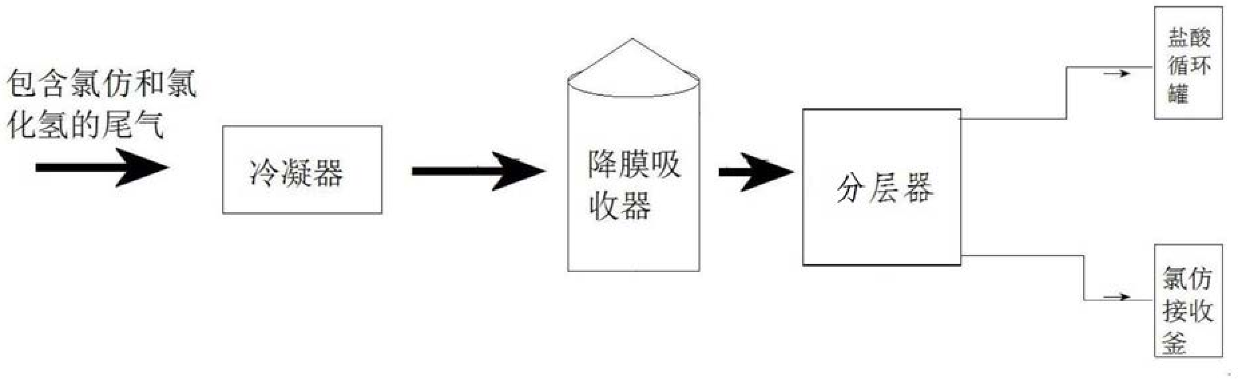

[0034] 1) The tail gas comprising chloroform and hydrogen chloride passes through the condenser to realize the condensation of chloroform gas. Most of the chloroform gas is condensed into a liquid state and captured, and the remaining chloroform and hydrogen chloride gas are sprayed into the hydrochloric acid mixed solution through the water spray of the falling film absorber; 2) the hydrochloric acid mixed solution in step 1) is cooled to 30 ° C, and then along the layered The tangential liquid inlet provided on the side of the stratifier is sent into the stratifier, and baffles and rotations occur in the baffles inside the stratifier to make the chloroform and hydrochloric acid settle and stratify. The overflow port set on the top flows into the hydrochloric acid circulation tank, and the chloroform f...

Embodiment 2

[0036] This embodiment discloses a method for recovering chloroform and hydrogen chloride in the production process of methyl isocyanate, which comprises the following steps:

[0037] 1) The tail gas comprising chloroform and hydrogen chloride passes through a condenser, wherein the condenser is used to condense chloroform gas. Most of the chloroform gas is condensed into a liquid state and captured, and the remaining chloroform and hydrogen chloride gas are sprayed into a hydrochloric acid mixture through the water spray of the falling film absorber;

[0038]2) The hydrochloric acid mixture in step 1) is cooled to 50°C, and then the tangential liquid inlet arranged along the side of the layerer is sent into the first layerer, and each layer arranged inside the first layerer The deflection and rotation occur in the baffle, so that the chloroform and hydrochloric acid settle and stratify. Among them, the hydrochloric acid flows into the hydrochloric acid circulation tank along ...

Embodiment 3

[0040] This embodiment discloses a method for recovering chloroform and hydrogen chloride in the production process of methyl isocyanate, which comprises the following steps:

[0041] 1) The tail gas comprising chloroform and hydrogen chloride passes through a condenser, wherein the condenser is used to condense chloroform gas. Most of the chloroform gas is condensed into a liquid state and captured, and the remaining chloroform and hydrogen chloride gas are sprayed into the hydrochloric acid mixed solution through the water spray of the falling film absorber; 2) the hydrochloric acid mixed solution in step 1) is cooled to 50 ° C, and then along the layered The tangential liquid inlet provided on the side of the device is sent into the stratifier. In this embodiment, three stratifiers are preferably arranged in series, that is, the tangential liquid inlets of adjacent stratifiers are connected to the liquid discharge ports. Other settings are the same as in Embodiment 2.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com