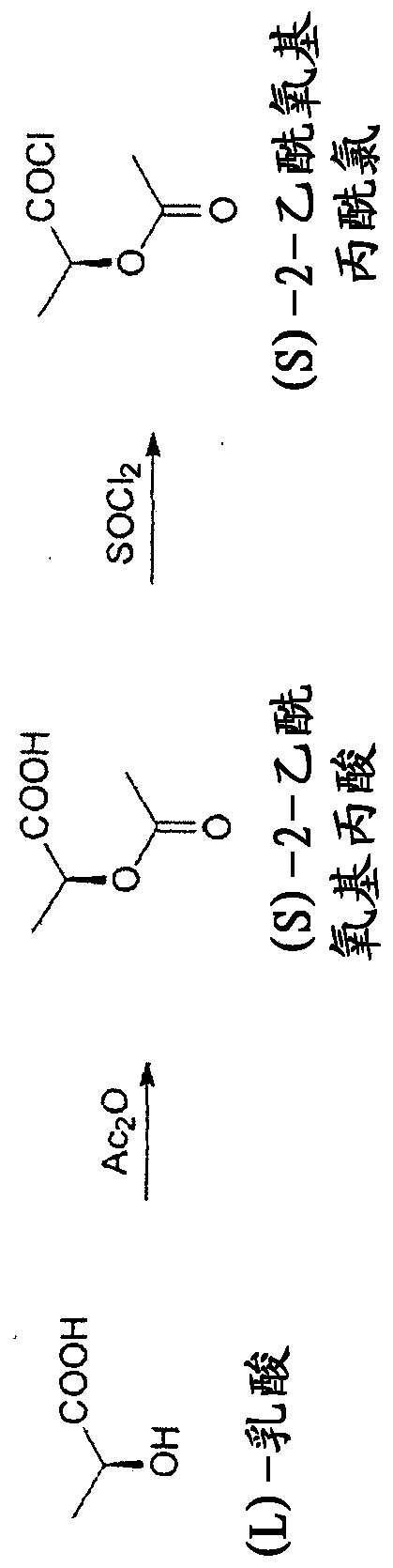

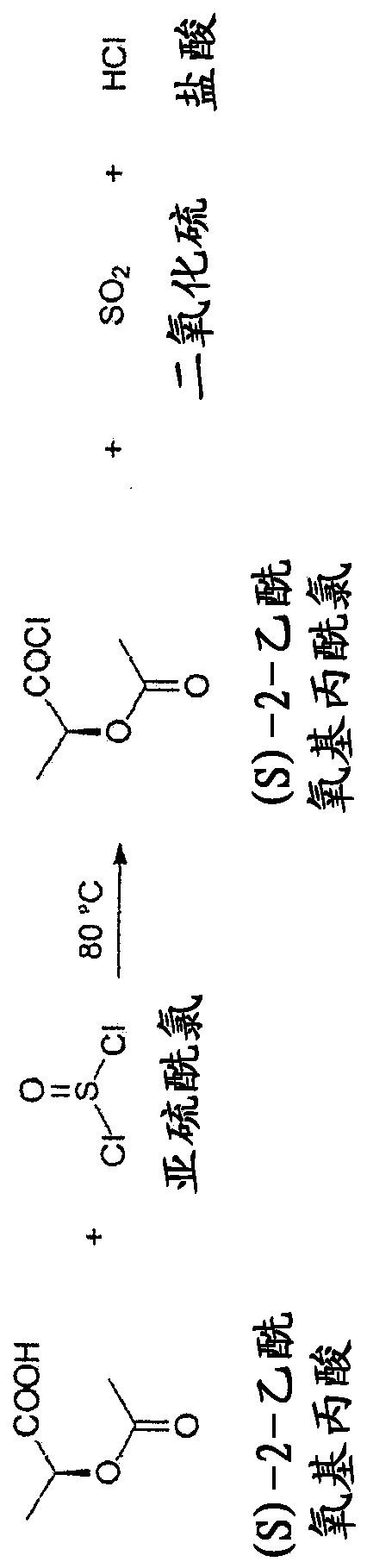

Continuous process for the preparation of (s)-2-acetyloxypropionic acid chloride

一种乙酰氧丙酰氯、乙酰氧基丙酸的技术,应用在制备(S)-2-乙酰氧基丙酰氯的连续领域,能够解决反应效率降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

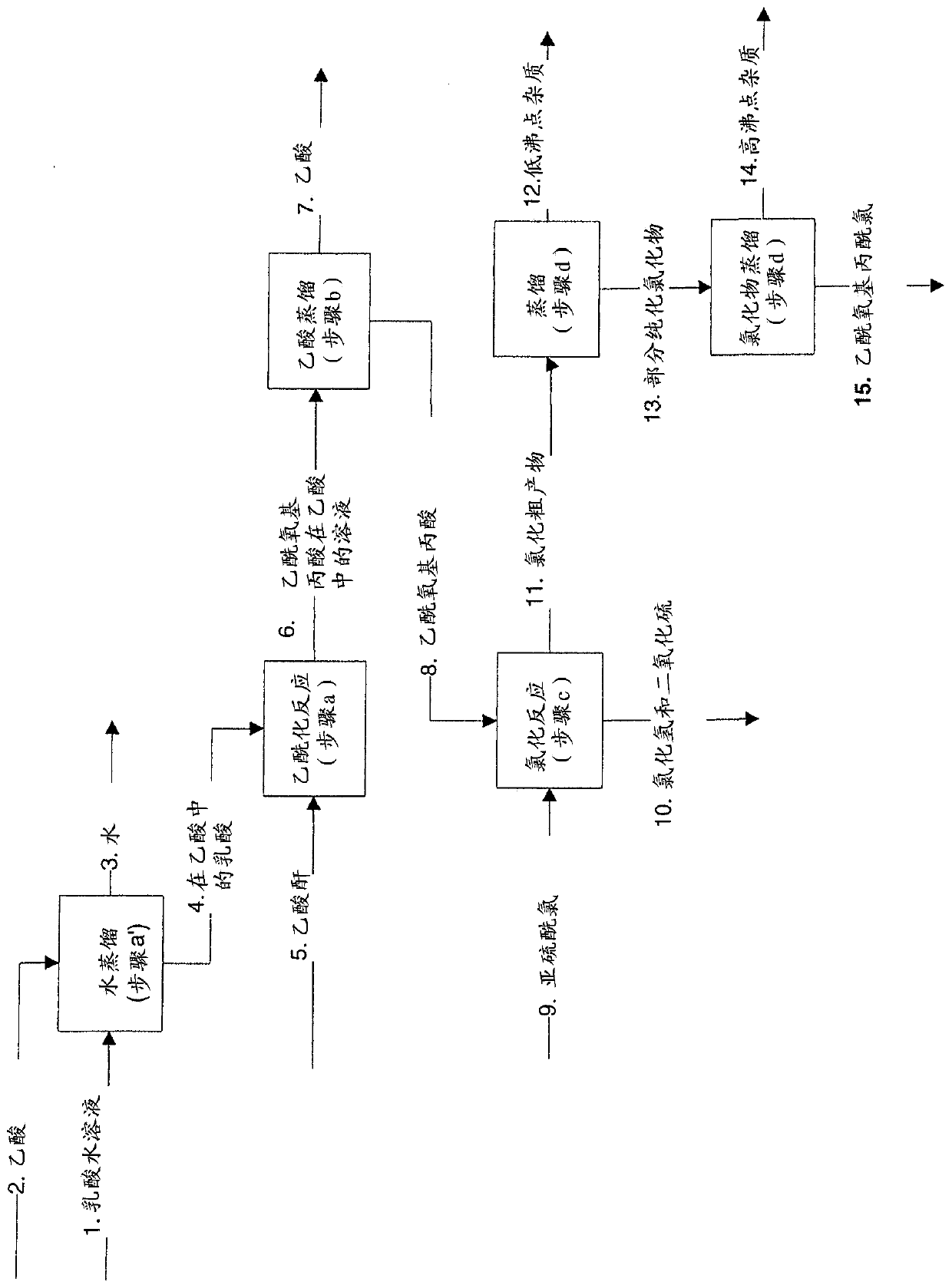

Method used

Image

Examples

Embodiment 1

[0095] Example 1: Preparation of Lactic Acid in Acetic Acid

[0096] A solution of commercially available lactic acid in water (containing 46.5% lactic acid monomer and 3.2% dimer) was fed from the top of an Oldershaw distillation column having a diameter of 5 cm and equipped with 30 orifice plates to the first tray, and metering was started, A stream of acetic acid is fed at its bottom. The flow rates of the two feeds were 1040 and 550 mL / h, respectively. The overhead pressure was 50 Torr and the reflux ratio was 1.

[0097] The distillate flow rate was 550 mL / h. The top product contained only water and traces of acetic acid, while the composition (% by weight) of the product from the bottom of the column was as follows:

[0098] Table 1

[0099] components weight% lactic acid 40.0 Lactic acid dimer 3.9 (S)-2-Acetoxypropionic acid 0.5 (S)-2-Acetoxypropionic acid dimer 0.3 water 2.8 Acetic acid 51.6

Embodiment 2

[0100] Example 2: Acetylation of Lactic Acid

[0101] a. Homogeneous catalysis

[0102] A lactic acid solution in acetic acid, containing 51.1% lactic acid and 5.9% oligomers, with an oligomer / lactic acid ratio equal to 0.11, was fed to a tubular reactor with a volume of 2.6 L and a diameter of 2 cm. The reactor was equipped with a thermostatic jacket. Inside the reactor, the fluid temperature was maintained at 57°C. The solution was fed into the reactor together with a stream of acetic anhydride containing sulfuric acid such that the molar ratio between acetic anhydride and lactic acid was a flow rate of 1.3 / 1. The concentration of sulfuric acid in the reaction mixture was 0.5% by weight. The residence time inside the reactor was 89 minutes, and the obtained conversions (%) are shown in Table 2. The effluent from the reactor was led continuously to an evaporator with a reboiler volume of 2 L, operated at 8 mbar, in which most of the acetic acid was removed by distillati...

Embodiment 3

[0117] Example 3: Chlorination of Acetoxypropionic Acid

[0118] 3.1 Preparation with 3 reactors and a condensing unit

[0119](S)-2-Acetoxypropionic acid, obtained from the bottom of the evaporator described in Example 1, was fed together with thionyl chloride into a continuous stirred reactor with reflux condensation unit and two horizontal tube reactions In a series of reactors (PFR1 and PFR2) formed in series, the reaction gases of which are directed to the condensation unit of the first stirred reactor. The condensate from each condensation unit is completely redirected to the first stirred reactor. The effective volumes of the three reactors are 586, 1380 and 1480 mL respectively, and the total volume is 3446 mL.

[0120] In addition to the acid itself, the acetoxypropionic acid solution contained 2% by weight of acetic acid, 6% by weight of acetylated dimer and about 2% of other products. The feed flow rate of the solution to the first reactor was 524.7 g / h, corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com