A kind of CO2 prevention for tight oil reservoirs 2 Gas channeling responsive interpenetrating network gel particles and preparation method thereof

A gel particle, interpenetrating network technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as difficulty in starting the matrix, excessive permeability difference, etc., achieve good response reversibility, increase regulation Intensity, the effect of increasing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Dissolve 48g of acrylamide, 6g of methacryloyl chloride-modified alkylphenol polyoxyethylene ether and 0.2g of N,N-methylenebisacrylamide into 150mL of distilled water using ultrasound;

[0037] (2) Slowly add 0.01 g of ammonium persulfate into the system, blow N2 for 30 minutes to remove oxygen in the system, raise the temperature to 50°C, and react for 4 hours to obtain a pre-crosslinked gel.

[0038] (3) The obtained gel is granulated, dried at 70° C., and then pulverized to obtain pre-crosslinked gel particles (ASSAP).

[0039] (4) Add the pre-cross-linked gel particles obtained in step (3) to the solution of 10g dimethylaminoethyl methacrylate, 0.03g 4,4'-azobis(4-cyanopentyl) under stirring condition acid) and 0.2g of N,N-methylenebisacrylamide in 100ml of deionized aqueous solution, let the mixture absorb water to swell for 24 hours, then raise the temperature to 70°C again, and react for 4 hours to obtain it.

[0040] (5) The obtained gel is granulated, dri...

Embodiment 2

[0044] Preparation of CO 2 The method of the responsive interpenetrating network gel particle is the same as that of Example 1, the only change is that in step (2), 0.1 g of ammonium persulfate is changed to 0.08 g of azobisisobutylamidine hydrochloride.

Embodiment 3

[0046]Preparation of CO 2 The method of the responsive interpenetrating network gel particle is the same as that in Example 1, the only change is that in step (4), dimethylaminoethyl methacrylate is replaced with dimethylaminopropyl methacrylamide.

[0047] (2) Performance test:

[0048] 1. CO 2 Responsive performance testing

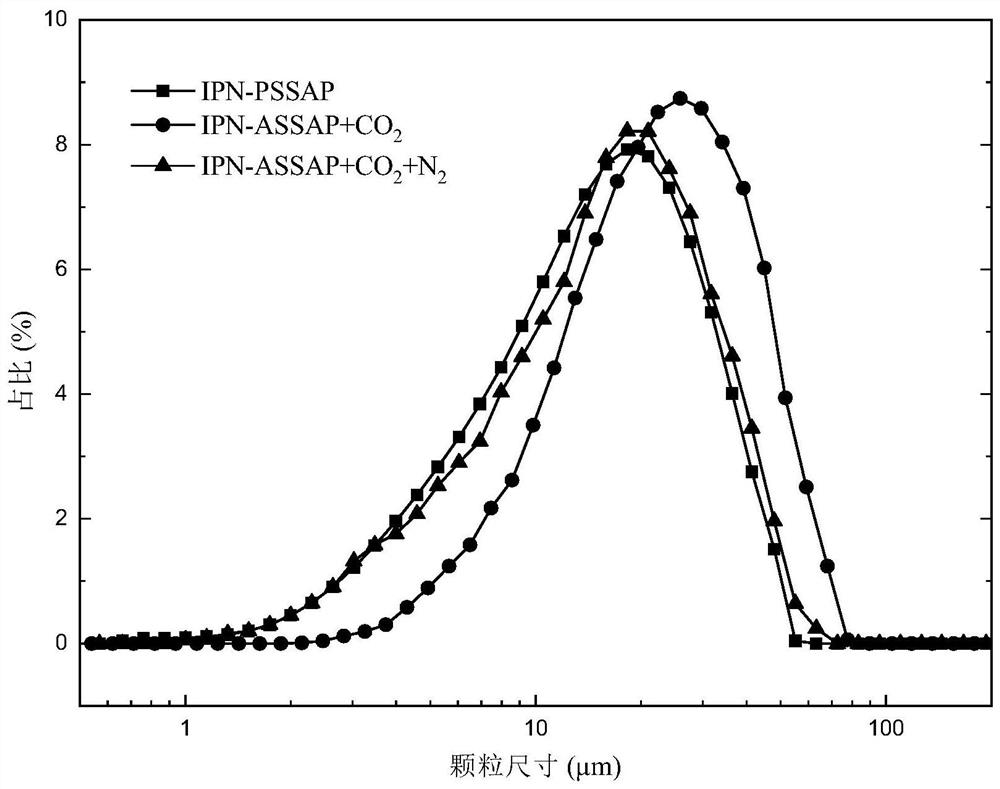

[0049] In order to test the CO of the present invention 2 Responsive interpenetrating network gel particles for CO 2 Responsiveness, take the CO in Example 1 2 Responsive interpenetrating network gel particles, using a laser particle size analyzer to measure CO influx into gel particles 2 The size distribution before and after is measured, and the specific test results are as follows figure 1 shown.

[0050] From figure 1 It can be seen that the CO 2 Before, the size distribution of the gel particles was 0.6 μm to 55 μm, and the median particle size was 18.24 μm; CO was introduced at a rate of 10ml / min 2 After 30 minutes, the size distribution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com