Ultralight/overweight non-silicon release film and preparation method thereof

A non-silicon release and release film technology, applied in the direction of film/sheet release liner, film/sheet adhesive, conductive coating, etc., can solve the silicon pollution of materials, silicon pollution of products, transfer to Protect the surface of the film glue and other problems, to achieve the effect of improving adhesion, aging release force stability, and high residual adhesion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of the above-mentioned ultra-light / ultra-heavy non-silicon release film, comprising the following steps:

[0041] Coat the antistatic primer on the substrate, and form an antistatic primer after baking;

[0042] 500-1000 parts of ester solvent, 50-500 parts of ketone solvent, 50-300 parts of amino-modified acrylic resin, 0-300 parts of hydroxyl-containing acrylic resin, and 5-50 parts of curing agent are configured into a coating liquid;

[0043] Coating the coating liquid on the antistatic primer layer, and forming a non-silicon release coating after baking;

[0044] After aging the semi-finished product obtained above, the finished non-silicon release film is obtained.

[0045] In the present invention, the antistatic primer layer is coated by dimple coating, extrusion coating or screen roll coating, and the wet coating amount is 6-10g / m 2 , The baking temperature after coating is 80-120°C, and the baking time...

Embodiment 1

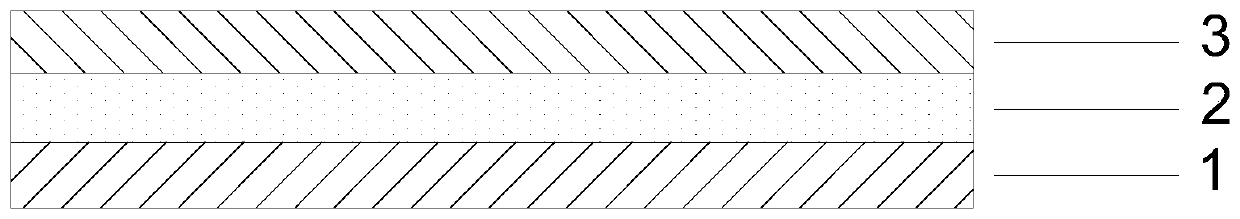

[0050] This embodiment provides a non-silicon release film resistant to high temperature and high humidity, including a substrate layer, an antistatic primer layer and a non-silicon release coating.

[0051] The formulation of the antistatic base coat is:

[0052] 5% polythiophene aqueous solution 100 parts

[0053] 10 parts of melamine curing agent

[0054] The above components are configured as an antistatic primer, and coated on a 50um PET substrate by using a dimple coating method, and the coating moisture is 6g / m 2 , baked in an oven after coating, the baking temperature is 105°C, and the baking time is 20 seconds to obtain an antistatic primer layer.

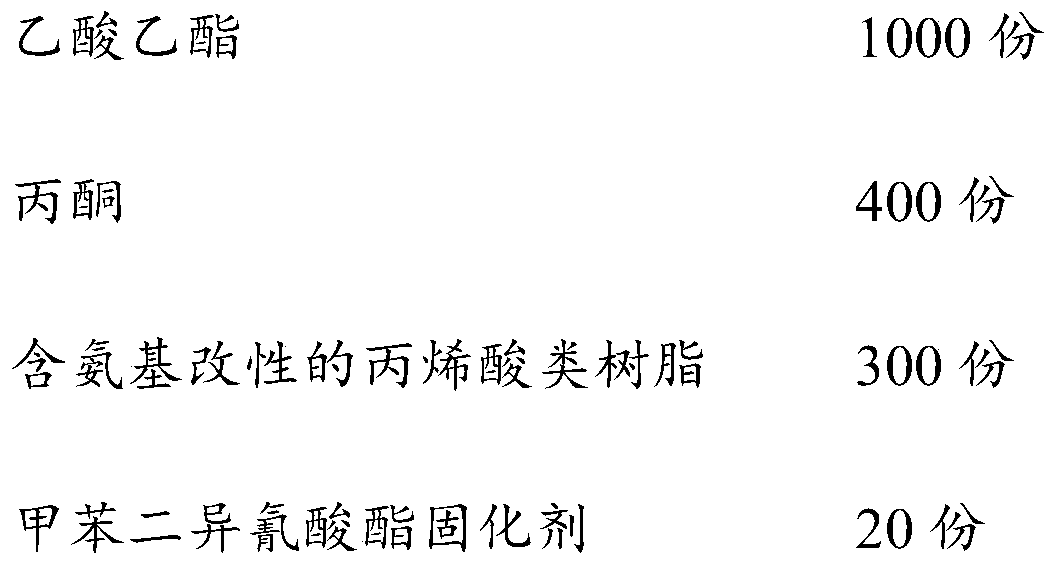

[0055] The formulation of the non-silicon release coating is:

[0056]

[0057] The above components are configured into a coating solution, which is coated on the antistatic primer layer by means of dimple coating, and the wet coating amount is 10g / m 2 , baked in an oven after coating, the baking temperature is 120...

Embodiment 2

[0059] This embodiment provides a non-silicon release film resistant to high temperature and high humidity, including a substrate layer, an antistatic primer layer and a non-silicon release coating.

[0060] The formulation of the antistatic base coat is:

[0061] 5% polythiophene aqueous solution 100 parts

[0062] 10 parts of melamine curing agent

[0063] The above components are configured as an antistatic primer, and coated on a 50um PET substrate by using a dimple coating method, and the coating moisture is 6g / m 2 , baked in an oven after coating, the baking temperature is 105°C, and the baking time is 20 seconds to obtain an antistatic primer layer.

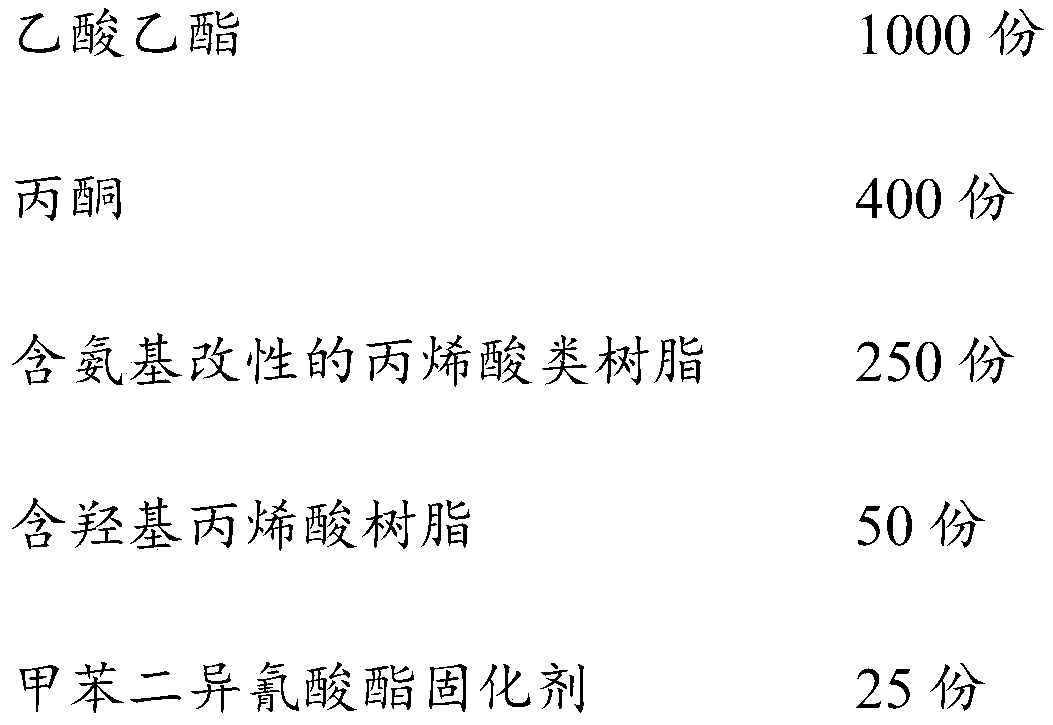

[0064] The formulation of the non-silicon release coating is:

[0065]

[0066] The above components are configured into a coating solution, which is coated on the antistatic primer layer by means of dimple coating, and the wet coating amount is 10g / m 2 , baked in an oven after coating, the baking temperature is 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com