Preparation method for preparing corn peptide by heat treatment assisted enzyme method

A technology of corn peptide and auxiliary enzyme, which is applied in the direction of fermentation, etc., can solve the problems of high molecular weight of corn peptide and different product quality, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

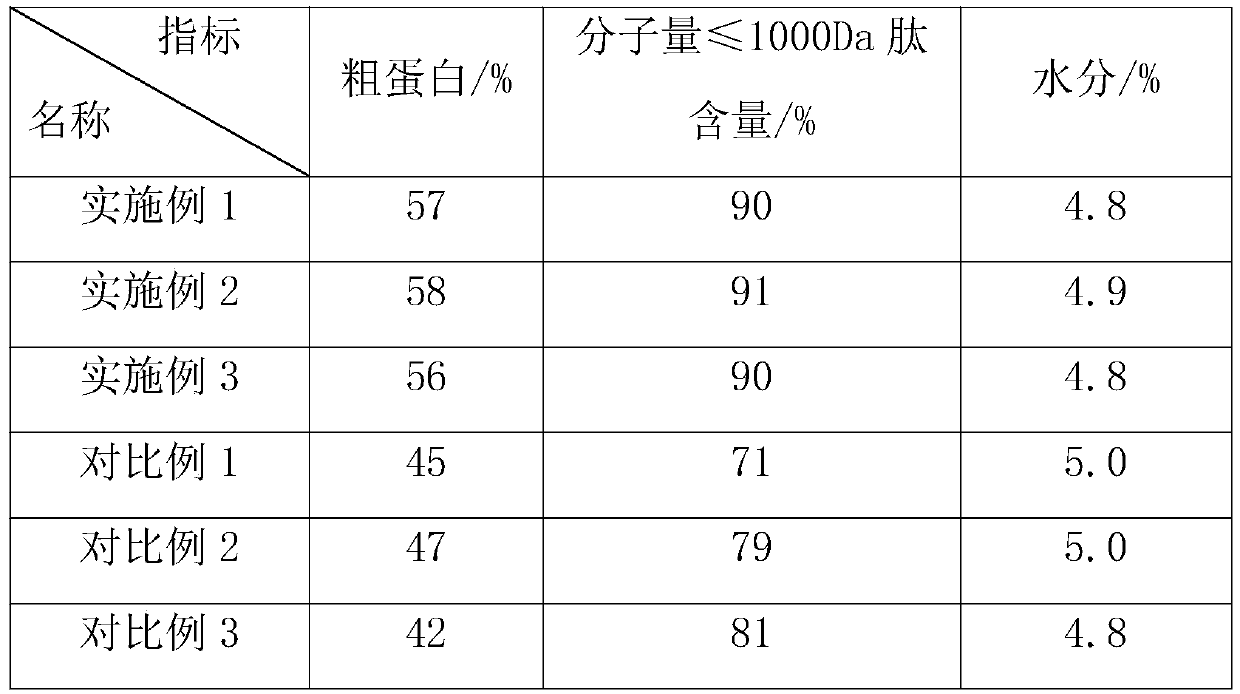

Examples

Embodiment 1

[0018] Step 1: Weigh 100g of corn gluten powder, crush and refine it, pass through a 40-mesh sieve for later use, and continue crushing particles with a particle size larger than 40-mesh sieve until all of them pass through a 40-mesh sieve, then add the crushed corn gluten powder to 733.3ml of distilled water Mix fully and evenly in the mixture to form a corn gluten powder solution with a solid content of corn gluten powder of 12%;

[0019] Step 2: Heat the corn gluten powder solution obtained in Step 1 to 115°C and keep it warm for 30 minutes;

[0020] Step 3: After heating in step 2, cool down to 55°C, add 0.8g of alkaline protease, 0.8g of neutral protease, and 0.8g of flavor protease, and perform enzymolysis reaction for 7 hours under stirring conditions;

[0021] Step 4: Dry the mixed liquid after the enzymolysis reaction in Step 3 at a temperature of 135° C. for 2.7 hours to obtain the corn peptide product.

Embodiment 2

[0023] Step 1: Weigh 100g of corn gluten powder, crush and refine it, pass through a 40-mesh sieve for later use, and continue crushing particles with a particle size larger than 40-mesh sieve until all of them pass through a 40-mesh sieve, then add the crushed corn gluten powder to 566.7ml of distilled water Mix well and evenly to form a corn gluten powder solution with a solid content of corn gluten powder of 15%;

[0024] Step 2: Heat the corn gluten powder solution obtained in Step 1 to 115°C and keep it warm for 40 minutes;

[0025] Step 3: After heating in step 2, cool down to 55°C, add 0.8g of alkaline protease, 0.8g of neutral protease, and 0.8g of flavor protease, and perform enzymolysis reaction for 8 hours under stirring conditions;

[0026] Step 4: Dry the mixed solution after the enzymolysis reaction in Step 3 at a temperature of 135° C. for 2 hours to obtain the corn peptide product.

Embodiment 3

[0028] Step 1: Weigh 100g of corn gluten powder, crush and refine it, pass it through a 40-mesh sieve for later use, and continue crushing particles with a particle size larger than 40 mesh sieve until all of them pass through a 40-mesh sieve, then add the crushed corn gluten powder to 900ml of distilled water to fully evenly Mixing and being configured into corn gluten powder solution with a solid content of corn gluten powder of 10%;

[0029] Step 2: Heat the corn gluten powder solution obtained in Step 1 to 115°C and keep it warm for 25 minutes;

[0030] Step 3: After heating in step 2, cool down to 55°C, add 0.6g of alkaline protease, 0.6g of neutral protease, and 0.6g of flavor protease, and perform enzymolysis reaction for 7 hours under stirring conditions;

[0031] Step 4: Dry the mixed liquid after the enzymolysis reaction in Step 3 at a temperature of 135° C. for 2.5 hours to obtain the corn peptide product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com