Method for operating a fuel system, control unit and fuel system

A fuel system and control unit technology, applied in fuel injection control, charging system, electrical control, etc., can solve the problem of slow gas pressure adjustment, achieve the effects of optimizing vibration performance, simplifying structure, and simplifying the fuel system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

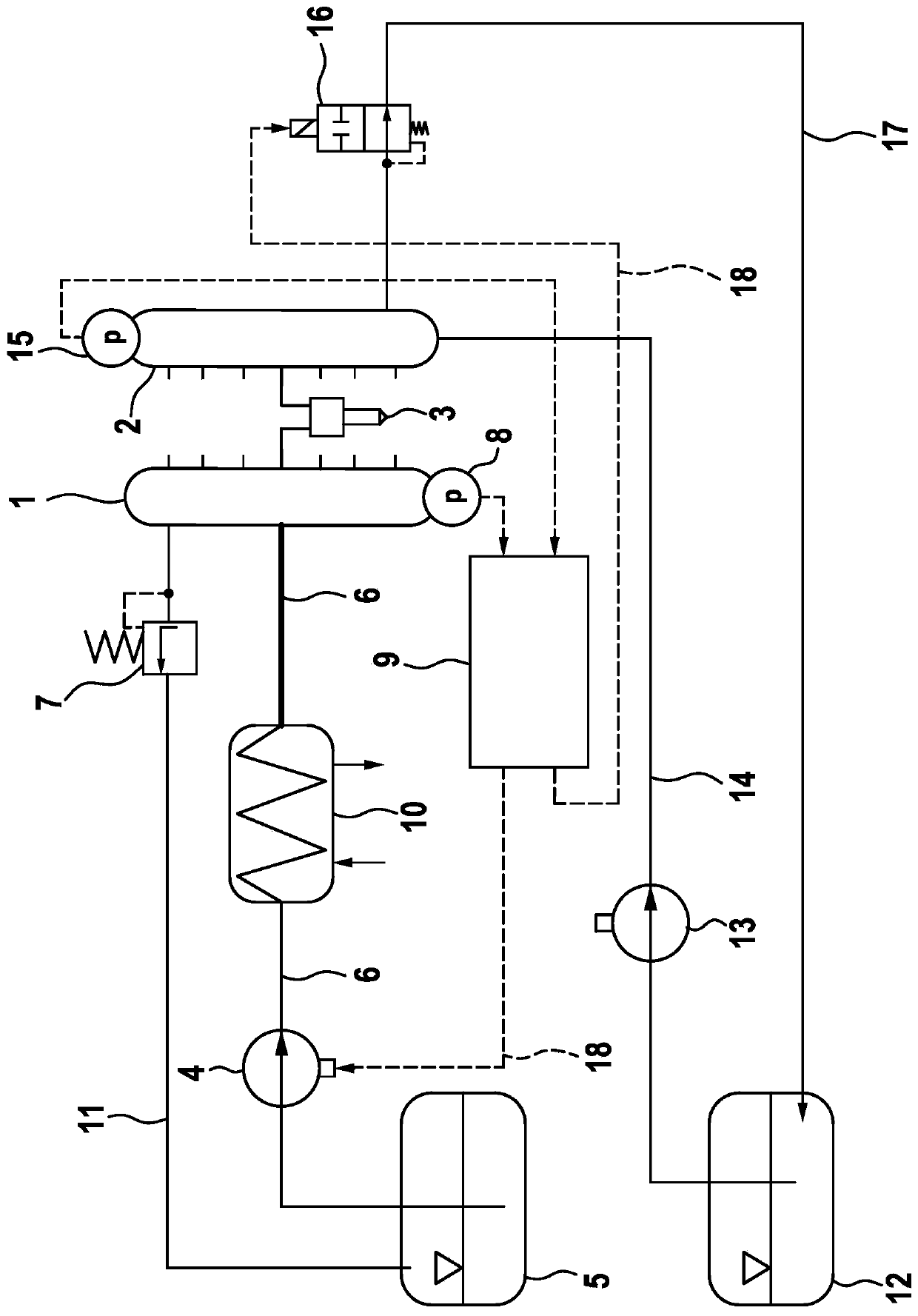

[0026] exist figure 1 The fuel system shown in is used to supply an internal combustion engine with a first gaseous fuel (such as natural gas) and a second liquid fuel (such as diesel fuel). The fuel is blown or injected into the combustion chamber of the internal combustion engine by means of at least one dual-mass injector 3 . At least one dual-mass injector 3 is supplied with both fuels via a gaseous rail 1 and a liquid fuel rail 2 , wherein the liquid fuel simultaneously serves as the control medium.

[0027] The fuel system shown comprises on the gas side a tank 5 which is connected to the gas rail via a gas supply line 6 and a fuel pump 4 by which gaseous fuel from the tank 5 can be supplied to the gas rail 1 . Furthermore, a heat exchanger 10 is arranged in the gas supply line 6 between the fuel pump 4 and the gas rail 1 . The section of the gas supply line 6 which connects the heat exchanger 10 to the gas rail 1 now has an increased flow diameter which leads to an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com