A kind of negative electrode material and its preparation method and application

A technology of negative electrode material and solution, applied in the field of negative electrode material and its preparation, can solve problems such as poor discharge performance at low temperature, and achieve the effects of improving mechanical strength, reducing resistance, and enriching in and out channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

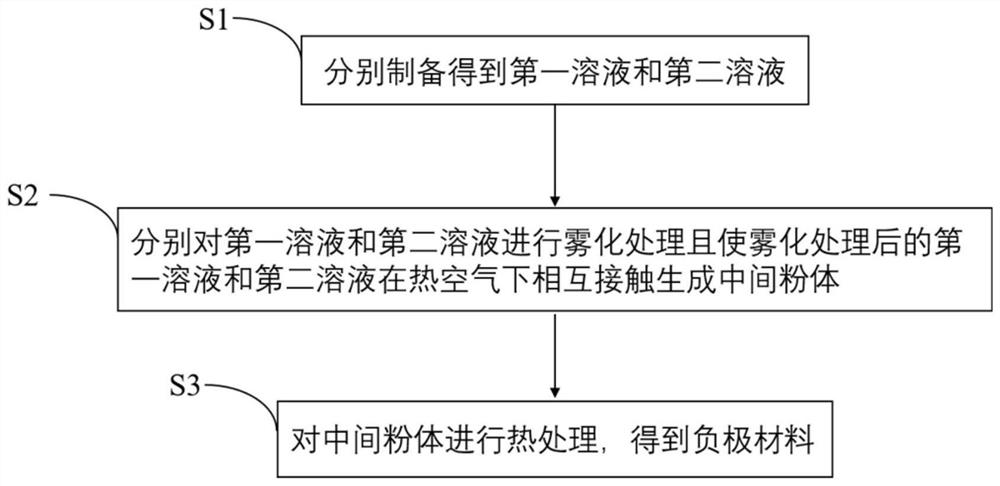

Method used

Image

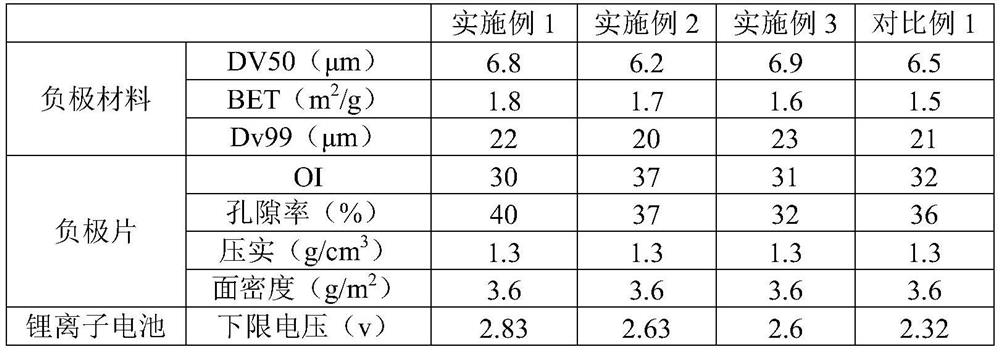

Examples

Embodiment 1

[0073] The negative electrode material provided in this example is prepared by the following preparation method:

[0074] 1. Under the protection of an inert atmosphere, 97 parts of mosaic coke were graphitized at 3000°C for 48 hours to obtain graphite particles, wherein the particle size range of mosaic coke was 1-3 μm;

[0075] 2. Disperse 2 parts of asphalt into tetrahydrofuran, stir evenly, add the graphite particles obtained in step 1, and obtain the first solution after carbonization, wherein the solid content of the first solution is 30%;

[0076] 3. Disperse 1 part of multi-walled carbon nanotubes in tetrahydrofuran and stir evenly to obtain a second solution, wherein the solid content of the second solution is 0.5%;

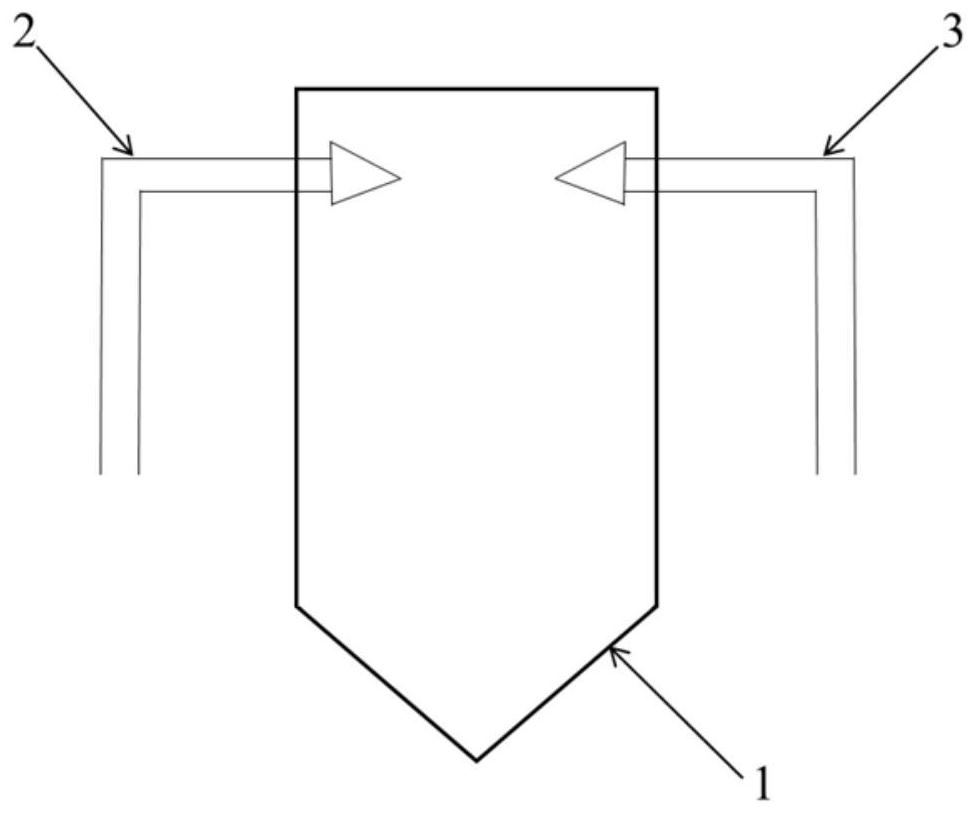

[0077] 4. Send the first solution into the spray drying chamber through the first solution injection gun, and send the second solution into the spray drying chamber from the second solution injection gun, so that the first solution and the second solution ...

Embodiment 2

[0086] The negative electrode material provided in this example is prepared by the following preparation method:

[0087] 1. Under the protection of an inert atmosphere, 97 parts of mosaic coke were graphitized at 3000°C for 48 hours to obtain graphite particles, wherein the particle size range of mosaic coke was 1-3 μm;

[0088] 2. Disperse 2 parts of asphalt into tetrahydrofuran, stir evenly, add the graphite particles obtained in step 1, and obtain the first solution after carbonization, wherein the solid content of the first solution is 30%;

[0089] 3. Disperse 1 part of multi-walled carbon nanotubes into tetrahydrofuran and stir evenly to obtain a second solution, wherein the solid content of the second solution is 0.3%;

[0090] 4. Send the first solution into the spray drying chamber through the first solution injection spray gun, and send the second solution into the spray drying chamber from the first solution injection spray gun, so that the first solution and the s...

Embodiment 3

[0094] The negative electrode material provided in this example is prepared by the following preparation method:

[0095] 1. Under the protection of an inert atmosphere, 97 parts of pitch coke were graphitized at 3000°C for 48 hours to obtain graphite particles, wherein the particle size range of pitch coke was 1-3 μm;

[0096] 2. Disperse 2 parts of asphalt into tetrahydrofuran, stir evenly, add the graphite particles obtained in step 1, and obtain the first solution after carbonization, wherein the solid content of the first solution is 30%;

[0097] 3. Disperse 1 part of multi-walled carbon nanotubes in tetrahydrofuran and stir evenly to obtain a second solution, wherein the solid content of the second solution is 0.5%;

[0098] 4. Send the first solution into the spray drying chamber through the first solution injection gun, and send the second solution into the spray drying chamber from the second solution injection gun, so that the first solution and the second solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com