Catalyst for methane carbon dioxide dry reforming reaction and its preparation method and application

A carbon dioxide and catalyst technology, applied in the field of Ni-MO@Silicalite-1 catalyst and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

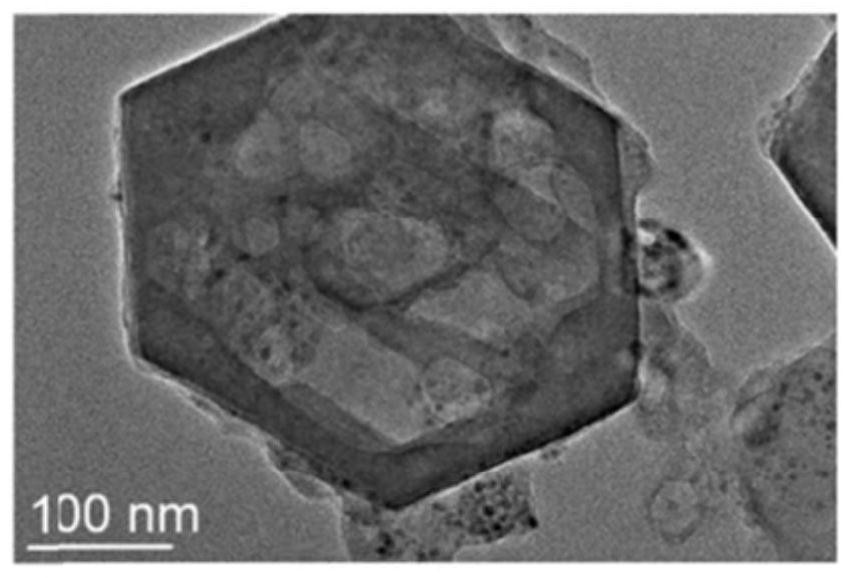

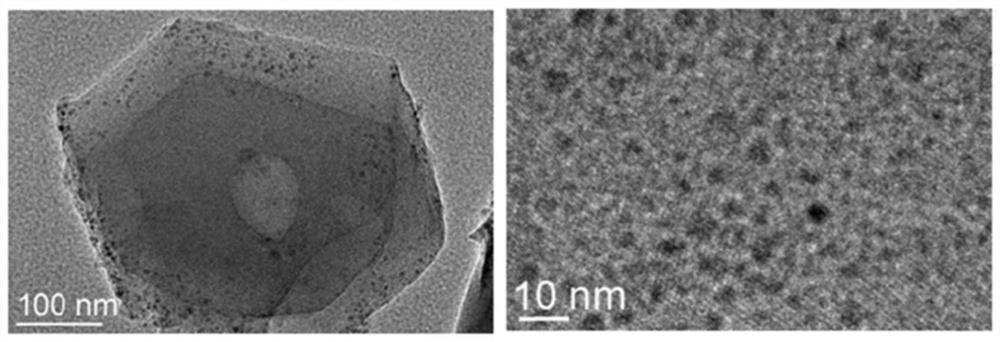

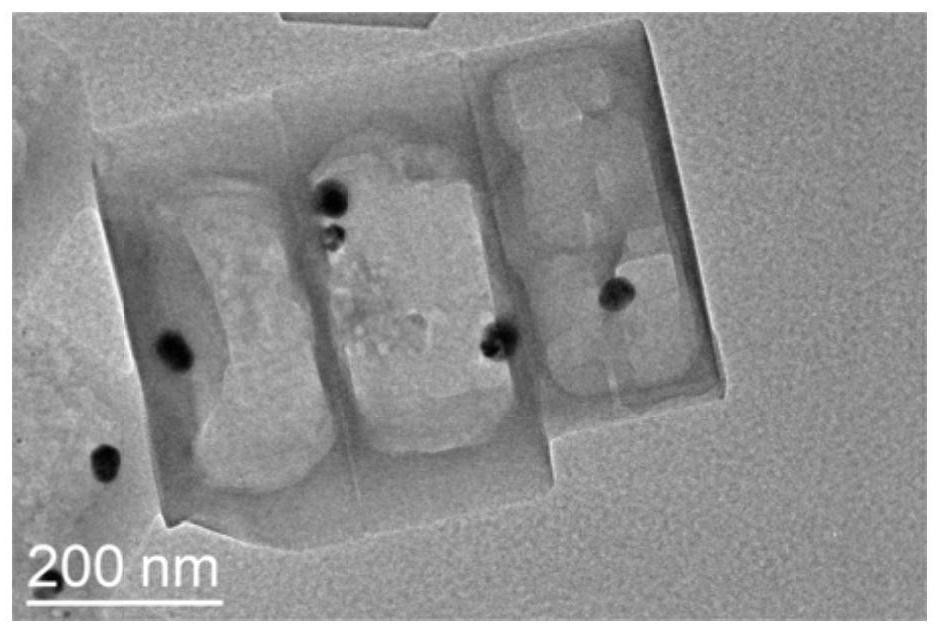

Image

Examples

preparation example Construction

[0033]Preparation of Silicalite-1 molecular sieve:

[0034] 45.83g of ethyl orthosilicate, 48.32g of tetrapropylammonium hydroxide (25wt.%), 40.54g of absolute ethanol and 145.92g of deionized water were uniformly mixed and stirred at 25°C for 5 hours. The resulting mixed liquid was poured into a hydrothermal kettle for hydrothermal crystallization at 170° C. for 72 hours. The resulting solid was dried by centrifugation and calcined in air at 540°C for 4 hours to obtain the Silicalite-1 parent molecular sieve.

Embodiment 1

[0036] 7.69g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 12 mL of deionized water. Then 6 grams of Silicalite-1 parent molecular sieve obtained by the above-mentioned Silicalite-1 molecular sieve preparation method was added thereto, stirred at 50° C. until dry, and ground into powder. Then the obtained powder was mixed with 58.6g of tetrapropylammonium hydroxide with a concentration of 25wt.% and 181.4g of deionized water, and poured into a hydrothermal kettle for hydrothermal crystallization at 170°C for 72 hours. After centrifugation, the resulting solid was dried and calcined in air at 540°C for 4 hours.

Embodiment 2

[0038] With 5.43g Ni(NO 3 ) 2 ·6H 2 O replaces 7.69g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 12 milliliters of deionized water, and other treatments were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com