Robot capable of adjusting welding height through arc voltage heightening system and welding method

A technology of arc voltage and welding method, which is applied in the field of robot welding, can solve problems such as uneven weld seam, poor forming, and difficulty in meeting welding requirements, and achieve satisfactory welding effect, good welding quality, and stable and consistent arc voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the accompanying drawings.

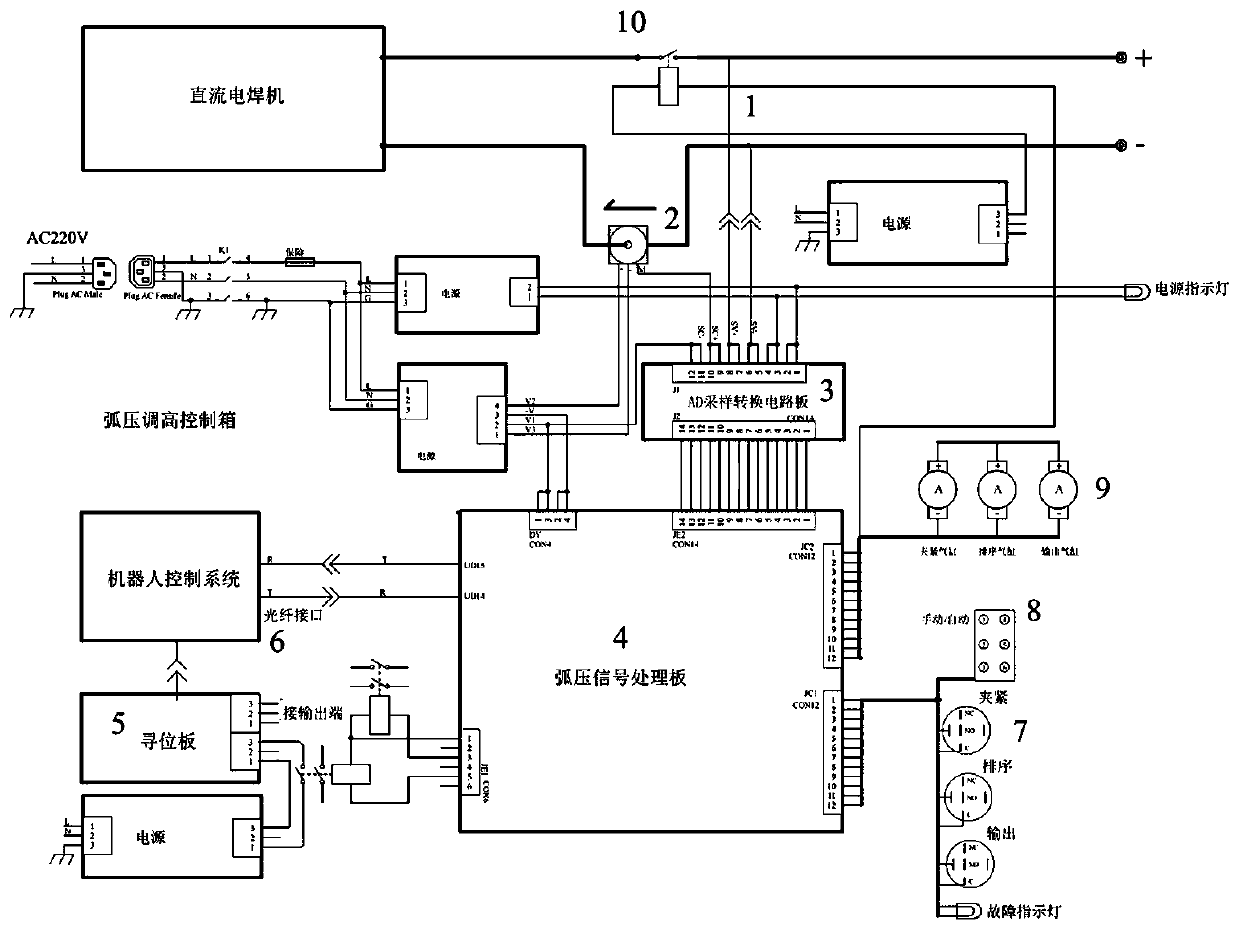

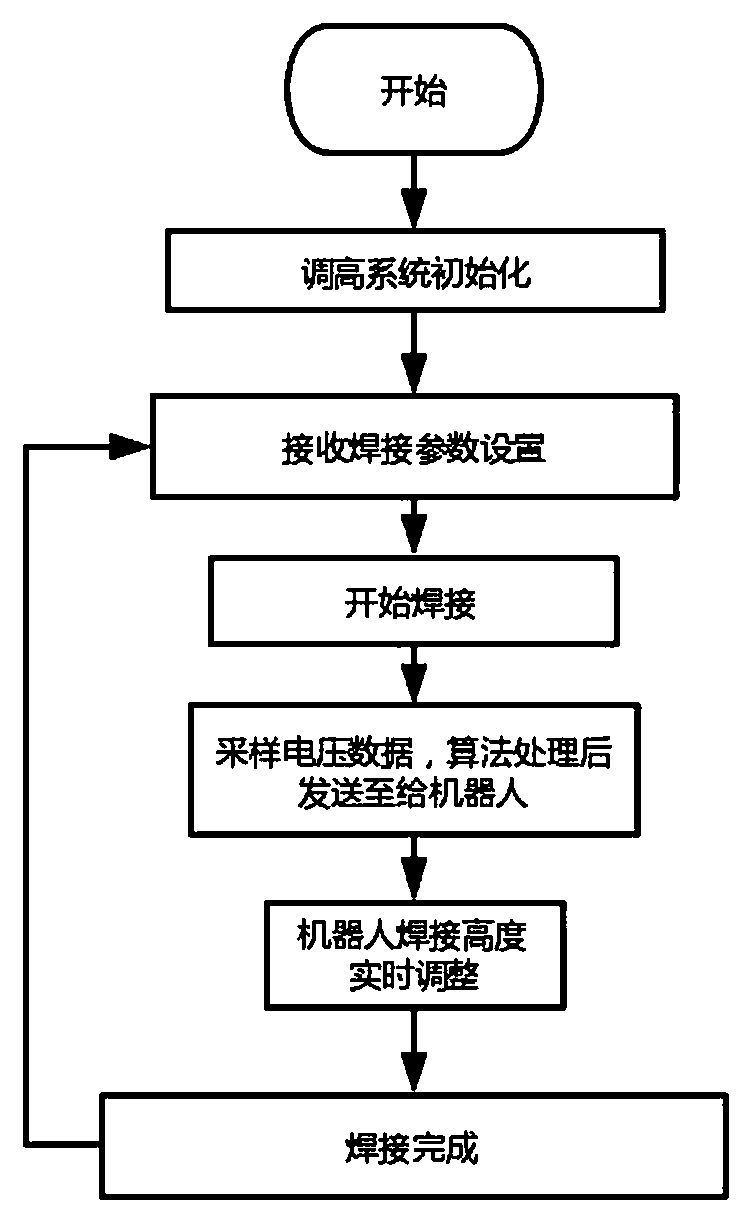

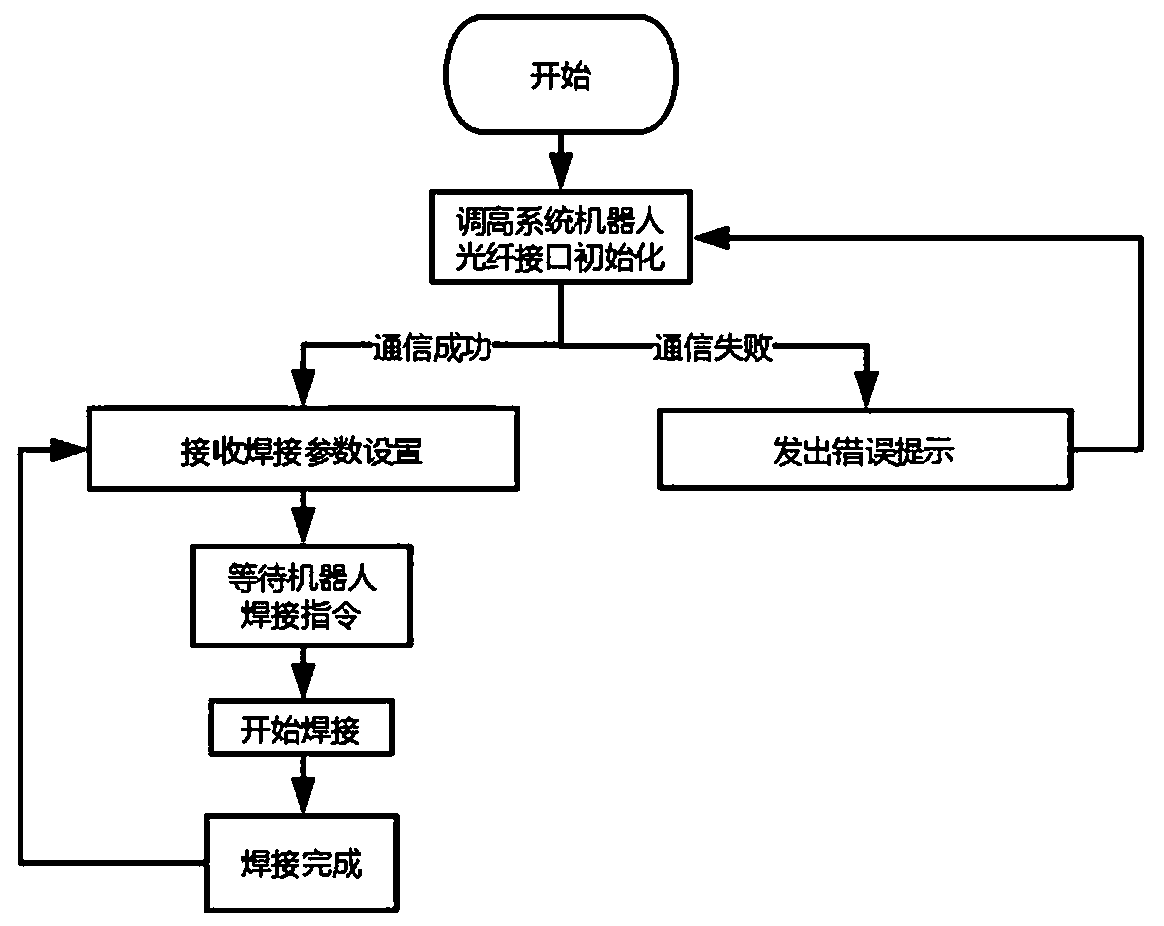

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a robot that adjusts the welding height through the arc voltage height adjustment system includes: a robot equipped with a welding machine; a workpiece to be welded; a robot positioning module for positioning the robot; a high-voltage contactor module for controlling On-off of the main circuit of the welding machine;

[0035] The robot also includes a welding arc voltage adjustment system and a robot control module, which are used to accurately sample the arc voltage of the welding machine and perform digital algorithm processing, and then upload appropriate arc voltage data to the robot control module for action;

[0036] The welding arc voltage adjustment system includes a voltage acquisition circuit,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com