Ceramic riving knife, surface roughening treatment method thereof, and semiconductor packaging method

A surface roughening and treatment method technology, applied in the field of ceramic materials, can solve problems such as reducing the service life of welding wires, and achieve the effect of eliminating internal stress and high service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

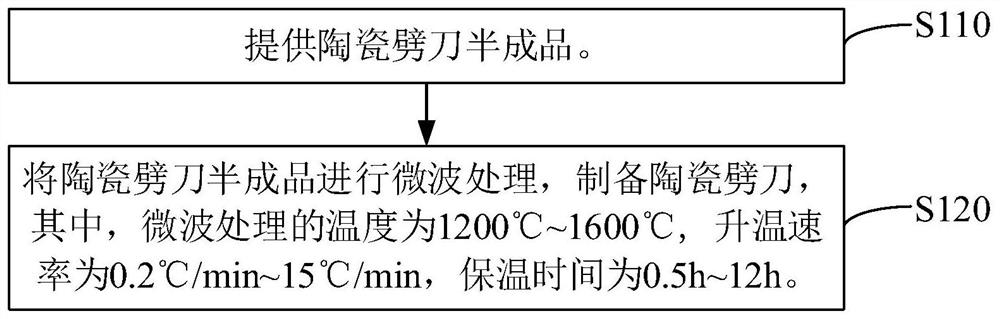

Method used

Image

Examples

Embodiment 1

[0043] The manufacture process of the ceramic riving knife of the present embodiment is specifically as follows:

[0044] Put the semi-finished alumina ceramic rivet in a microwave processing equipment, set the heating rate at 3°C / min, raise the temperature to 1450°C, and keep it warm for 3.5 hours to obtain the ceramic rivet of this embodiment.

Embodiment 2

[0046] The manufacture process of the ceramic riving knife of the present embodiment is specifically as follows:

[0047] Put the semi-finished alumina ceramic rivet in a microwave processing equipment, set the heating rate at 2°C / min, raise the temperature to 1400°C, and then keep it warm for 4 hours to obtain the ceramic rivet of this embodiment.

Embodiment 3

[0049] The manufacture process of the ceramic riving knife of the present embodiment is specifically as follows:

[0050] Put the semi-finished alumina ceramic rivet in a microwave processing equipment, set the heating rate at 5°C / min, raise the temperature to 1500°C, and then keep it warm for 3 hours to obtain the ceramic rivet of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com