Chitosan derivative, preparation method and application thereof

A technology of chitosan derivatives and chitosan, which is applied in the direction of analysis by chemical reaction of materials and material analysis by observing the influence on chemical indicators, can solve the problems of cumbersome and time-consuming operation process, etc. Achieve good recognition effect and achieve highly specific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method step of chitosan derivative that the present invention proposes is as follows:

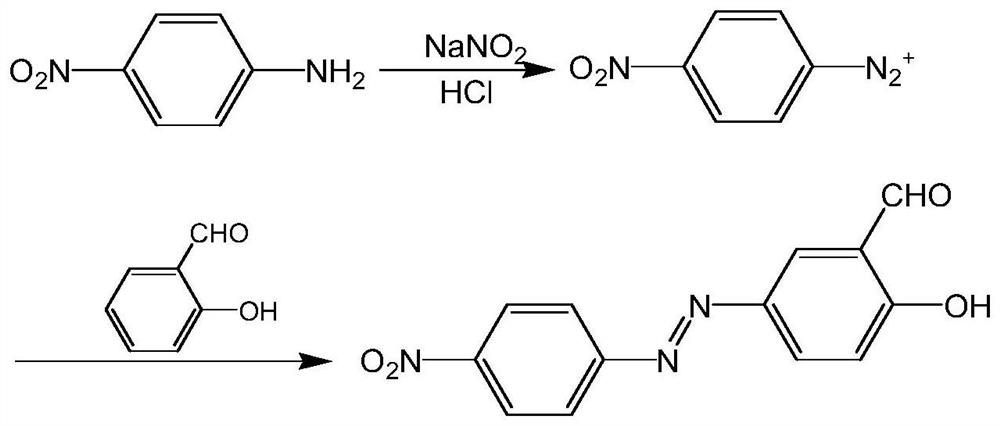

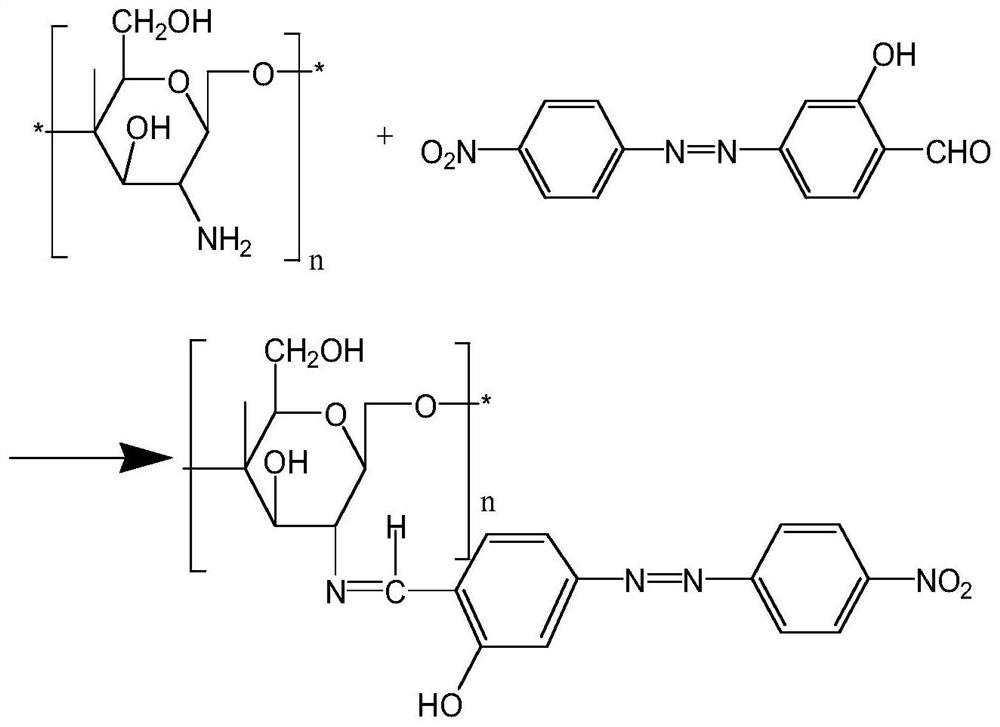

[0040] S1: Synthesis of 4-(p-nitrobenzene)-azosalicylaldehyde, its synthetic route reference figure 1 ;

[0041] S2: Degradation of chitosan: Dissolve chitosan in acetic acid solution, stir at room temperature for 1 hour to completely dissolve chitosan, adjust pH to 8 with sodium hydroxide solution, obtain flocculent chitosan precipitate, and let the precipitate stand Suction filtration after 1 hour, and repeated washing twice, and drying in a vacuum oven at 40°C for 10 hours to obtain degraded chitosan, which was finely ground for later use;

[0042] S3: Modification of Chitosan:

[0043] (1) Dissolve the degraded chitosan in the S2 in absolute ethanol, stir and swell at room temperature for 20h, and record it as solution A,

[0044] (2) 4-(p-nitrobenzene)-azosalicylaldehyde of the S1 is dissolved in absolute ethanol, and then mixed with solution A, which is recor...

Embodiment 2

[0072] The preparation method step of chitosan derivative that the present invention proposes is as follows:

[0073] S1: Synthesis of 4-(p-nitrobenzene)-azosalicylaldehyde;

[0074] S2: Degradation of chitosan: Dissolve chitosan in acetic acid solution, stir at room temperature for 3 hours to completely dissolve chitosan, adjust pH to 9 with sodium hydroxide solution, obtain flocculent chitosan precipitate, and let the precipitate stand Suction filtration after 3 hours, and repeated washing 4 times, drying in a vacuum oven at 80°C for 14 hours to obtain degraded chitosan, which was finely ground for later use;

[0075] S3: Modification of chitosan:

[0076] (1) Dissolve the degraded chitosan in S2 in absolute ethanol, stir and swell at room temperature for 28h, and record it as solution A,

[0077] (2) 4-(p-nitrobenzene)-azosalicylaldehyde of the S1 is dissolved in absolute ethanol, and then mixed with solution A, which is recorded as solution B,

[0078] (3) Solution B wa...

Embodiment 3

[0091] The preparation method step of chitosan derivative that the present invention proposes is as follows:

[0092] S1: Synthesis of 4-(p-nitrobenzene)-azosalicylaldehyde;

[0093] S2: Degradation of chitosan: Dissolve chitosan in acetic acid solution, stir at room temperature for 2 hours to completely dissolve chitosan, adjust pH to 8.5 with sodium hydroxide solution, obtain flocculent chitosan precipitate, and let the precipitate stand Suction filtration after 2 hours, and repeated washing for 3 times, drying in a vacuum oven at 60°C for 12 hours to obtain degraded chitosan, which was finely ground for later use;

[0094] S3: Modification of chitosan:

[0095] (1) Dissolve the degraded chitosan in S2 in absolute ethanol, stir and swell at room temperature for 24h, and record it as solution A,

[0096] (2) 4-(p-nitrobenzene)-azosalicylaldehyde of the S1 is dissolved in absolute ethanol, and then mixed with solution A, which is recorded as solution B,

[0097] (3) Solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com