A kind of bismuth-containing ultrafine copper-based pre-alloyed powder and its preparation method and application

A pre-alloyed powder and copper-based technology, which is applied in the field of bismuth-containing ultra-fine copper-based pre-alloyed powder and its preparation, can solve the problems of fine-grained diamonds that cannot be cut out of the blade height, cannot use metal binders, and have short service life. Green and environmental protection processing technology, easy and rapid self-sharpening wear, high sintering density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

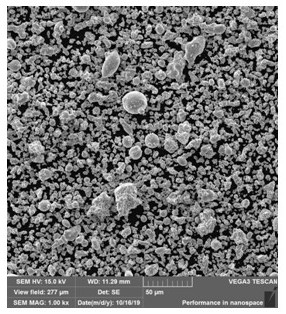

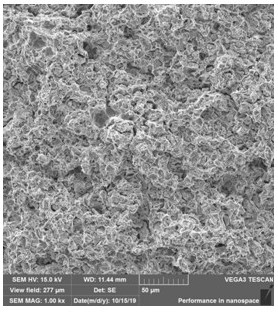

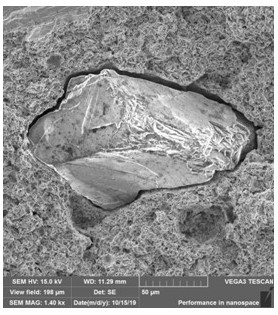

Image

Examples

Embodiment 1

[0031] A bismuth-containing ultrafine copper-based pre-alloyed powder, which comprises the following components by weight ratio: 7% Sn, 8% Bi, 1% P, and 84% Cu, which uses 250kg furnace capacity and furnace lining material It is an intermediate frequency induction smelting furnace for magnesia, and it is prepared by water mist process.

[0032] The specific raw materials and weight are as follows:

[0033]

[0034] Among them, in the P-Cu block, the content of P is 14%.

[0035] Specific steps are as follows:

[0036] Add Cu, Sn, Bi, P into the medium frequency induction furnace in turn, energize to melt and refine, deoxidize by adding carbon powder, adjust the superheat of the melt to 150-200°C, pour it into the tundish, and the melt passes through After the bottom of the bag leaks, it is crushed by high-pressure water and atomized into powder in an atomizing barrel filled with nitrogen protection. After atomization, the powder is fully dehydrated by vacuum filtration, ...

Embodiment 2

[0040] A bismuth-containing ultrafine copper-based pre-alloyed powder, which comprises the following components by weight ratio: 15% Sn, 15% Bi, 3% P, 67% Cu, which uses 250kg furnace capacity and furnace lining material It is an intermediate frequency induction smelting furnace for magnesia, and it is prepared by water mist process.

[0041] Raw materials and weight are as follows:

[0042]

[0043] Among them, in the P-Cu block, the content of P is 14%.

[0044]The specific steps are as follows: sequentially add Cu, Sn, Bi, P into the medium frequency induction furnace, energize, melt and refine, deoxidize by adding carbon powder, adjust the superheat of the melt to 150-200°C, and pour it into the tundish , After the melt passes through the leakage hole at the bottom of the bag, it is crushed by high-pressure water, and atomized into powder in the atomizing barrel filled with nitrogen protection. After atomization, the powder is fully dehydrated by vacuum filtration, pu...

Embodiment 3

[0048] A bismuth-containing ultrafine copper-based pre-alloyed powder, which comprises the following components by weight ratio: 20% Sn, 20% Bi, 3% P, and 57% Cu, which uses 250kg furnace capacity and furnace lining material It is an intermediate frequency induction smelting furnace for magnesia, and it is prepared by water mist process.

[0049] Raw materials and weight are as follows:

[0050]

[0051] Among them, in the P-Cu block, the content of P is 14%.

[0052] The specific steps are as follows: sequentially add Cu, Sn, Bi, P into the medium frequency induction furnace, energize, melt and refine, deoxidize by adding carbon powder, adjust the superheat of the melt to 150-200°C, and pour it into the tundish , After the melt passes through the leakage hole at the bottom of the bag, it is crushed by high-pressure water, and atomized into powder in the atomizing barrel filled with nitrogen protection. After atomization, the powder is fully dehydrated by vacuum filtratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| laser granularity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com